|

|||||||||||

|

|

|||||||||||

|

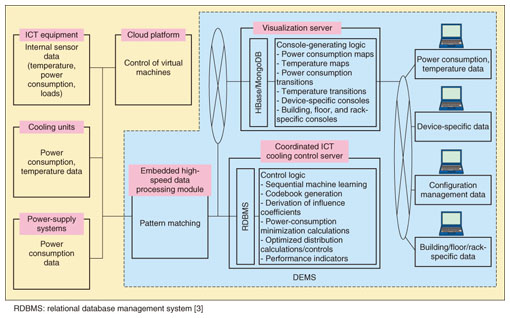

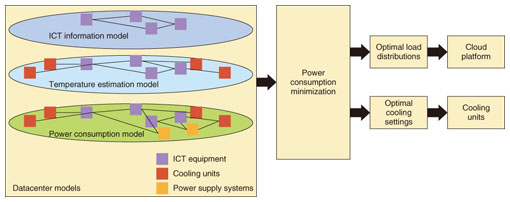

Feature Articles: Environmental and Energy Technologies for ICT Society Vol. 11, No. 1, pp. 10–16, Jan. 2013. https://doi.org/10.53829/ntr201301fa2 Reducing Datacenter Energy Consumption Using Coordinated ICT-cooling Control Technology of Datacenter Energy Management SystemAbstractThis article describes research efforts underway in NTT Energy and Environment Systems Laboratories in the area of datacenter energy management systems (DEMSs), which are systems designed to reduce energy consumption in datacenters and other telecommunication buildings. We present a new energy-saving system that comprises coordinated control of multiple cooling systems to minimize cooling power consumption, integration with information and communications technology (ICT) equipment to extend the benefits of the cooling-system controls, and high-speed data processing that can be adapted to large-scale datacenters. 1. IntroductionEnergy consumption in datacenters has been increasing annually in recent years, driven by the rapid growth of cloud services. Information and communications technology (ICT) equipment, cooling units, and power supply systems account for the majority of energy consumed in datacenters. The energy use breakdown in one example revealed that 45% of the total energy was consumed by ICT equipment, 30% by cooling units, and 18% by power supply systems [1]. NTT has been researching and developing datacenter energy management systems (DEMSs) as a technology to cut energy consumption in datacenters and telecommunication buildings [2]. Our research has led to advances in coordinated ICT-cooling control technology that links multiple cooling units and regulates load distributions among ICT equipment to lower the total energy costs of ICT equipment, power supply systems, and cooling units. We have also examined high-speed data processing technology designed to process the large amounts of device information within a datacenter. A block diagram of the DEMS-coordinated ICT-cooling control architecture is shown in Fig. 1. The DEMS consists of a visualization server that enables operators to view temperatures and power consumption within the datacenter, a coordinated ICT-cooling control server, and an embedded high-speed data processing module. The visualization server collects temperature, power consumption, and load data using sensors inside ICT equipment rather than external sensors. It then provides fine distributions of the temperatures and power consumption of all the devices within the datacenter. The coordinated ICT-cooling control server takes the visualization server's sensor data and calculates the optimal cooling settings and ICT equipment load distributions to minimize the power consumption of cooling units and ICT equipment. The server then accordingly adjusts the cooling controls and controls the ICT equipment's virtual machines and power supply systems via a cloud platform. The embedded high-speed data processing module quickly implements the optimized cooling settings and load distributions. It does this not by recalculating optimized values but by implementing pattern matching of sensor data using a codebook of optimal cooling settings and optimal load distributions calculated by the coordinated ICT-cooling control server.

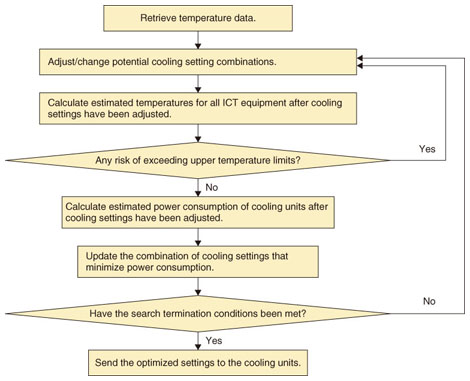

2. Coordinated ICT-cooling control technologyCooling unit assets located in datacenters and telecommunication buildings have conventionally been operated independently of other control systems. NTT Energy and Environment Systems Laboratories in partnership with NTT Facilities, Inc., has been working to raise cooling efficiency by unifying the controls that manage ICT equipment and multiple cooling units. An optimization problem can be formulated to find the combination of cooling settings that 1) ensure ICT equipment does not exceed its upper temperature limits and 2) minimize the overall power consumption. A flowchart governing the coordinated control of multiple cooling units is shown in Fig. 2.

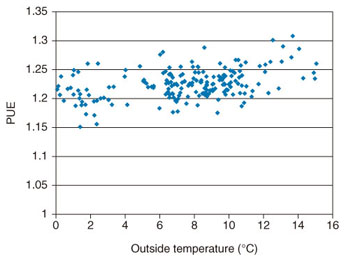

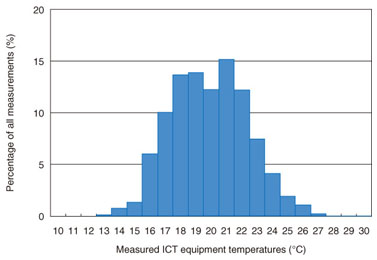

The first step necessary in implementing such controls is to develop a technique to estimate ICT equipment temperatures in response to changes in cooling unit settings. A temperature estimation equation can be found by analyzing data obtained during actual datacenter operation for the correlation between cooling-unit temperature changes and ICT equipment temperature changes. A model of power consumption by cooling units is also necessary. The problem is the difficulty and calculation cost of deriving an accurate model, since cooling-unit power consumption is affected by multiple parameters. To test and demonstrate the savings in cooling energy using the control flowchart mentioned above, we decided to use as our test case a linear model of cooling temperature settings for temperature estimates and cooling-unit power consumption. An automatic control system using prototype software was constructed in a server room containing 9 cooling units and over 1000 operating servers. The test results are shown in Figs. 3 and 4. The test system obtained an average power usage effectiveness (PUE) [4] of 1.225 while maintaining ICT equipment temperatures at proper levels (at or under 27°C). Although the trials were done in an environment conducive to favorable PUE values, as aisle capping* was implemented in a season with low external temperatures, the system did demonstrate that practical results could be achieved even with a linear model for temperature estimates and power consumption.

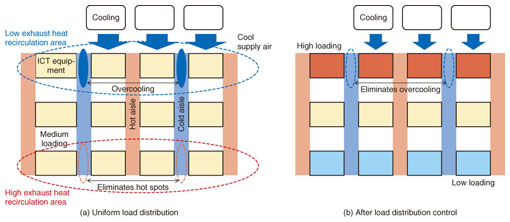

We believe that in addition to balanced control of multiple cooling units, coordinated ICT-cooling controls that regulate ICT equipment loads can further reduce datacenter energy consumption. Controlling ICT equipment via cloud platforms can reduce the number of pieces of equipment in operation and consequently reduce the load on the cooling system. Additionally, further controls of the loads placed on working ICT equipment can be added to raise the cooling system's efficiency. In this way, coordinated ICT-cooling control technology can cut the overall power consumption of ICT equipment while simultaneously reducing the cooling system's energy costs. This leads to the problem of determining which ICT equipment to run and how to distribute the load. At a typical datacenter, warm exhaust air of ICT equipment is recirculated with the cold supply air to other ICT equipment, and this lowers the cooling system's efficiency. Thus, governing loads in such a way as to minimize the recirculation of exhaust air is an effective means of reducing cooling power consumption. The DEMS uses a temperature estimation model that includes the temperature relationship between cooling and ICT equipment to forecast ICT equipment temperatures for a given load situation. Next, the DEMS sets limiting conditions on load distributions to implement the required cloud services with an ICT information model. This model, provided from a cloud platform, describes the relationship between cloud services and the ICT equipment necessary to deliver the cloud services. The DEMS finds a power consumption model for the ICT equipment, power supply systems, and cooling units and calculates cooling settings and load distributions that will minimize power consumption while meeting temperature conditions and load distribution constraints derived from the temperature estimation model and the ICT information model. The calculated load distribution is sent to a cloud platform, which adjusts the ICT equipment and the power supply systems. Cooling units are controlled following the calculated cooling settings (Fig. 5).

In datacenters that have areas with high and low volumes of recirculated heat from ICT equipment, hot spots—where ICT equipment near high recirculation areas runs hotter than that near low recirculation areas—will form if loads are distributed uniformly. In these cases, the cooling system works to eliminate the hot spots so that no ICT equipment operates above their upper temperature limits. Unfortunately, this results in overcooling of ICT equipment near low-recirculation areas. Without proper load distribution controls, the existence of excessively cooled ICT equipment means the cooling system is using more energy than necessary. The DEMS, however, implements load distribution controls to allocate larger loads to ICT equipment near low-recirculation areas and lighter loads to that near high-recirculation areas and, thus, equalizes temperatures between devices. The DEMS combines load controls with coordinated cooling unit controls to calculate optimal cooling settings and eliminate overcooling conditions (Fig. 6). In the actual system, the relative amount of heat recirculation is accounted for in the temperature estimation model that describes the temperature relationship between cooling and ICT equipment. In the model, the ICT equipment temperature is given as a function of the cooling settings and the load distribution. The DEMS then calculates the combination of cooling settings and load distributions that both meets ICT equipment maximum temperature limits and minimizes cooling power consumption. This optimization uses mathematical programming and other techniques.

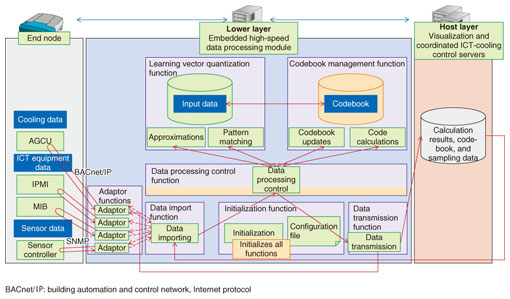

3. High-speed processing technology for time-series numerical dataWhen the DEMS must collect data from thousands of pieces of ICT equipment in a datacenter or telecommunication building, and thousands of external sensors are installed to collect temperature and power consumption data, the sensor maintenance operations become exceedingly complex, and the cost is prohibitive. To overcome these problems, we investigated the possibility of collecting temperature, power consumption, and other data of ICT equipment using standard protocols, for example, the simple network management protocol (SNMP) or the Intelligent Platform Management Interface (IPMI), to construct a highly reliable, inexpensive, sensor-less system. Another issue we faced was how to process data inexpensively and energy-efficiently when calculating the optimal settings for multiple cooling units and the optimal load distribution among hundreds of pieces of ICT equipment from large data sets. Ordinary hardware solutions that scale up to meet increased calculation costs (i.e., distributing the processing load over additional servers) result in greater power consumption and higher costs. Our solution was to focus on a scalable architecture that contributes to reducing power consumption. In the DEMS data collection layer (lower layer), we implemented a high-speed processing module specialized for time-series numeric data that has interfaces to collect data from SNMP management information bases (MIBs) and from IPMIs. This module makes rapid adjustments to cooling unit controls and ICT equipment load distributions based on the collected data to minimize overall power consumption (Fig. 7).

The module collects cooling data, ICT equipment data, and other external sensor data through interface adaptors with air-conditioner group control units (AGCUs), MIBs, and IPMIs. The module manages a codebook generated from optimization calculations run by the host server and from input data in order to effect cooling controls and ICT equipment load distributions. Learning vector quantization is used for codebook pattern matching with sensor data as the input. In this way, quasi-optimal cooling settings and load distributions are found without redoing the optimization calculations, which would require significant calculation costs. The quasi-optimal settings are sent to the cooling system and cloud platforms via interface adaptors to control the actual cooling units and ICT equipment. The module is capable of very high-speed processing because it is done in memory without any database access. We also believe the module can be implemented with inexpensive hardware because the approach uses quasi-optimal solutions instead of combinatorial computing and other costly optimization calculations. 4. Future research directionsNTT is moving ahead with energy-efficient datacenter trials in which the cooling and ICT control technology discussed in this article will be linked with cloud platforms. References

|

|||||||||||