|

|||||||||

|

|

|||||||||

|

Regular Articles Vol. 12, No. 6, pp. 50–56, June 2014. https://doi.org/10.53829/ntr201406ra1 Inspection Prioritizing Technique for Early Discovery of Defective Facilities––Manhole Facility Inspection PrioritizationAbstractThere are approximately 680,000 manholes throughout Japan, and as most of these facilities were built more than 30 years ago, aging-related problems have begun to appear. Consequently, the maintenance and management of communications-infrastructure facilities carried out from this point on will become increasingly important and will have to be done in a more efficient manner. In this article, we introduce a technique for analyzing data previously collected during facility inspections and for giving priority to inspecting facilities with a high probability of deterioration in order to achieve early discovery of defective manholes. Keywords: manholes, communications infrastructure facilities, deterioration 1. IntroductionCommunications infrastructure facilities constitute a vitally important social infrastructure for accommodating the underground communication cables that support our advanced information society. Most of these facilities, which include conduits, manholes, and tunnels, were built in the 15-year period from the latter half of the 1960s to the end of the 1970s, which means that about 80% of them are now more than 30 years old. Left as such, these facilities will be more than 50 years old in about 20 years time and will begin to age in earnest (Fig. 1). Concrete structures such as manholes can weaken with age as a result of cracks, peeling, corrosion of reinforcing bars, and other problems.

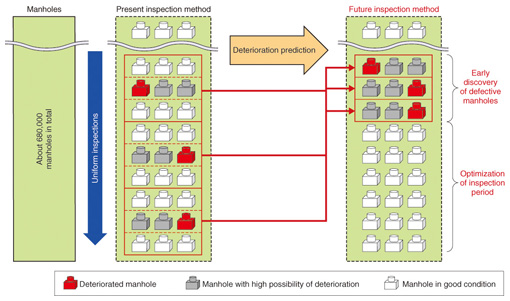

The ideal way of dealing with aging facilities would be to renovate them in a systematic manner. However, renovating a huge number of underground manholes would be costly and time-consuming and is therefore unrealistic for all practical purposes. In addition, digging up roads is obviously troublesome for the surrounding environment. For these reasons, there is a need to conduct appropriate maintenance without having to carry out complete renovation so that such facilities can continue to be used for a long period of time. At present, the inspection of a manhole located under a road requires that approval be obtained for using that road and that safety measures be put into place. It also requires considerable labor such as ventilating the manhole, performing a toxic-gas check, and pumping out standing water before inspectors can enter the manhole and begin the inspection. The current system, moreover, involves inspecting all manhole facilities in a uniform and exhaustive manner on an area-by-area basis. From here on, defective manholes*1 must be discovered early from the huge number of aging facilities and repaired accordingly, and inspections must be tailored to the conditions of individual facilities. With this in mind, we have been developing a condition-based maintenance and management technique that enables us to predict the deterioration of a manhole from its installation environment and facility structure (Fig. 2).

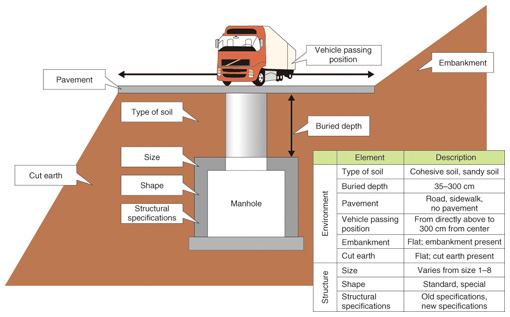

2. Overview of inspection prioritizing techniqueCauses of manhole deterioration can be broadly divided into external and internal factors. The former consists of external forces such as soil pressure and vehicle loads, and the latter refers to material deterioration such as the corrosion of reinforcing bars and neutralization of concrete. In our research, we first clarified the relationship between the generation of cracks—a form of deterioration caused by external factors—and the installation environment. Then, we analyzed past manhole inspection data taking those factors of crack generation into consideration. We used the results to develop an inspection prioritizing technique for extracting facilities likely to be in a state of deterioration and prioritizing them for repair. 3. Relationship between cracks caused by external forces and installation environmentTwo types of forces act on manholes buried underground: soil pressure and the load from vehicles passing on the road above. However, the impact on the manhole does not depend solely on the magnitude of those two forces; it will depend greatly on the installation environment such as the type of soil, underground depth, and thickness of the road pavement as well as on the size and shape of the manhole itself. We reproduced these diverse conditions using finite element method (FEM) analysis*2. In creating a FEM model for manholes, we examined the behavior of actual manholes when subjected to realistic conditions by conducting a pressure-application test using a full-size test specimen, and we verified the reproducibility of that behavior (Figs. 3 and 4). We also narrowed down variables of concern in the installation environment to nine items that have a major affect on the external forces acting on the manhole. We combined those items with data on the facility structure and analyzed about 300 patterns of manhole installation states (Fig. 5). Here, on the basis of knowledge obtained through past experiments with concrete specimens that a crack will be generated at a tensile strain of 100 με, we set the threshold for crack generation to be the value obtained by multiplying the above value of tensile strain by a safety factor. This factor takes into account an impact coefficient related to the difference in grade level between the road and the manhole cover, and repeated loading, as obtained from wheel-load experiments.

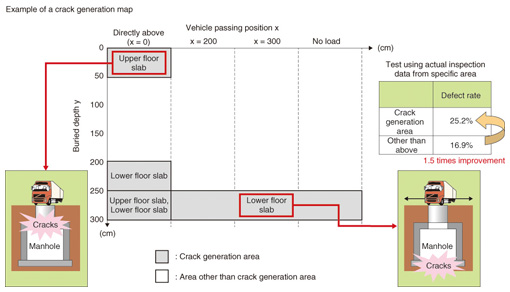

The results of analysis revealed that the threshold for crack generation set as described above would be exceeded for certain combinations of the underground depth of the manhole, referred to as the manhole buried depth, and the vehicle passing position. To easily determine those combinations, we created a crack generation map with one axis assigned to the buried depth and the other to the vehicle passing position (Fig. 6). This map revealed that, in general, a shallowly buried manhole receives the load of a vehicle passing directly above and that its upper floor slab (ceiling portion of the manhole interior) experiences a large amount of strain. It also revealed that a deeply buried manhole suffers from the effects of soil pressure and that its lower floor slab (floor portion of the manhole interior) experiences a large amount of strain regardless of the vehicle passing position. We tested these analysis results using actual manhole inspection data from a certain area and found that the defect rate of manholes corresponding to the crack generation areas of this map was indeed 1.5 times greater than that of other manholes.

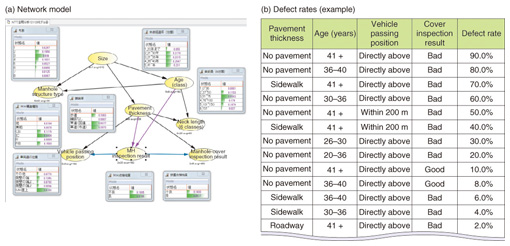

4. Analysis of inspection dataAt first, we analyzed inspection data using only inspection items and the facility information, but identifying the inspection items that had a high possibility of influencing a defective inspection result proved difficult. We therefore decided to focus our attention on items such as vehicle passing position and defects in manhole cover and peripheral pavement, which were found to have a relationship with external forces from the FEM analysis. We then performed data mining. Here, we adopted the Bayesian network technique*3, which makes it possible to visualize dependency relationships among data items and flexibly incorporate tacit knowledge of experienced inspectors in the model-creation process. In this way, we first prepared a network model showing defective inspection results and the dependency relationship among data items. We then improved the acceptance of this model by holding discussions with local maintenance departments and making modifications as needed, and we checked the validity of the defect rates in this network model through a process of trial and error (Fig. 7). In the end, we identified four items having a dependency relationship with an inspection result of defective (that is, features common to a defective manhole). These items are thickness of pavement, age of manhole, result of inspecting manhole cover (has the manhole cover been defective in the past?), and vehicle passing position, the last of which also played a role in the FEM analysis. These items included those that had not been obtained as inspection data in the past, and we adjusted for their future acquisition with the NTT business companies of concern.

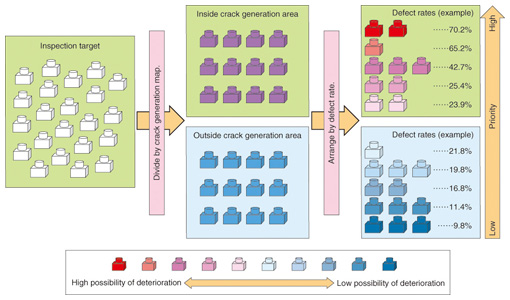

5. Inspection prioritizing techniqueInspection prioritizing begins by dividing up the manholes targeted for inspection according to whether a manhole falls within a crack generation area in the crack generation map prepared by FEM analysis. This step gives priority to manholes that are heavily affected by external forces. Next, we take the four items found to be common to defective facilities in the analysis of actual inspection data, classify each manhole according to a certain combination of those items, and sort the manholes according to the defect rates previously calculated for those combinations. In this way, priority can be given to inspecting those manholes that are heavily affected by external forces and that have a high defect rate (Fig. 8).

We conducted a case study using about 9000 sets of manhole data. Assuming that about 20% of all manholes can be inspected in one year, we prioritized their inspection using the technique described above. Compared to the conventional inspection method, the proposed technique improved the discovery rate of defective manholes by up to two times in the first year, and by the third year, we were able to discover 80% of the defective manholes. In fiscal year 2013, we used this technique to prioritize facilities targeted for inspection in a certain area and conducted manhole inspections. At first, we were concerned that inspection efficiency would decrease since the manholes targeted for inspection were extracted without regard to contiguous installation locations and were consequently scattered in various areas. However, since many causes of manhole deterioration originate in the characteristics of roads, the facilities extracted using the proposed technique tended to be located along the same routes. Although only half the number of targeted manholes has so far been inspected in that area, the discovery rate of defective manholes is running at about twice that of the conventional method. These results demonstrate that the proposed technique is practical and effective for early discovery of defective manholes.

6. Future plansAt present, we are focusing our studies on the speed of corrosion in concrete reinforcing bars as a type of deterioration caused by internal factors. Our objective here is to set an optimal inspection period based on the progression of deterioration. We will continue to research and develop techniques for appropriately maintaining and managing infrastructure facilities at low cost with the aim of contributing to enhanced operations in the NTT Group. Reference

|

|||||||||