|

|||||||||||

|

|

|||||||||||

|

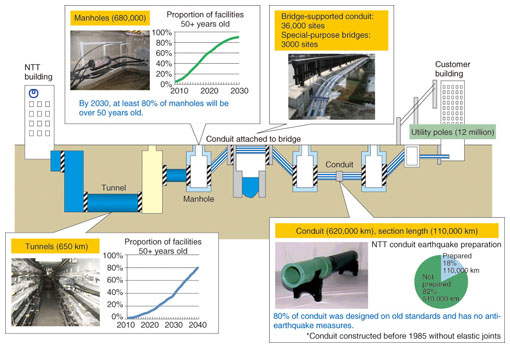

Feature Articles: R&D on Maintenance and Management Technologies for Telecommunication Infrastructure Vol. 12, No. 10, pp. 5–10, Oct. 2014. https://doi.org/10.53829/ntr201410fa1 Maintenance and Management Technology for Safe, Secure, and Economical Operation of Telecommunication Infrastructure FacilitiesAbstractThe conduits, manholes, tunnels, and other telecommunication infrastructure facilities that support optical access networks are aging rapidly, just as roads, bridges, and other elements of the social infrastructure are. The ability of these facilities to withstand large-scale earthquakes is also a major concern. These Feature Articles describe the latest technical trends in facilities management, inspection and diagnosis, repair and reinforcement, and technology for making facilities resistant to earthquake damage as part of efforts to achieve safe and secure telecommunication infrastructure facilities as well as economical maintenance. Keywords: telecommunication infrastructure facilities, maintenance and management, age deterioration 1. IntroductionThe aging of roads, bridges, tunnels, and other elements of the social infrastructure is becoming a severe social problem. Dealing with this problem is an urgent matter for governments at the national and local levels and the enterprises that manage infrastructure facilities. However, the huge cost and insufficient number of technicians are hindering an early solution. Furthermore, there is no systematic knowledge or standard technology for dealing with aging infrastructure facilities, so managers of the facilities are left to devise measures individually. Accordingly, there is a growing expectation by governments and society as a whole for the development of technology to address the problem. Another equally important problem is the need to strengthen facilities against major earthquakes. The probability of a Nankai Trough earthquake or an earthquake directly beneath the Tokyo area is high, and the resulting damage to infrastructure facilities, especially facilities deteriorated by age, would be immeasurable. NTT telecommunication infrastructure facilities, including conduits, manholes, and tunnels, would not escape that damage. For example, about 80% of the manholes will be over 50 years old (the service life for such facilities) by 2030 (Fig. 1). Currently, 80% of the existing conduit is not equipped with earthquake resistance measures, and the problems that require solutions are mounting. In developing new business on the B2B2C (Business-to-Business-to-Consumer) model, NTT is pressing forward with the expansion of optical access systems, and having safe and secure telecommunication infrastructure facilities is important in order to provide stable support of such NTT services.

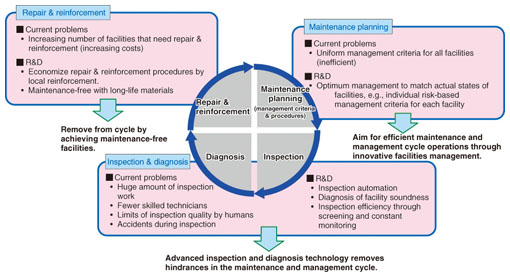

Research on telecommunication infrastructure facilities at the NTT Access Network Service Systems Laboratories has spanned many years, and we are applying the technology and research expertise we have developed while gathering knowledge acquired by other NTT laboratories and other companies to solve such problems. 2. Direction of research and development (R&D) related to telecommunication infrastructure facilitiesThe NTT Access Network Service Systems Laboratories is concentrating on developing maintenance and management technology for safe, secure, and economical maintenance of telecommunication infrastructure facilities. By making the results of that work widely applicable to infrastructure facilities in Japan and other countries, rather than only within NTT, we hope to contribute, if only to a small degree, to solving a problem faced by society in general. In our R&D on maintenance and management technology, we are going beyond the conventional research topics such as repair procedures and tools for inspection and diagnosis, by taking an overall view of the maintenance and management performed by NTT business companies and working on more innovative management strategies. We cannot keep up with the rapid aging of a huge number of facilities by increasing the efficiency of individual inspection and repair tasks alone. We can see by looking at the maintenance and management cycle (Fig. 2) that a radical change is needed. We are focusing on this challenge from the three viewpoints described below.

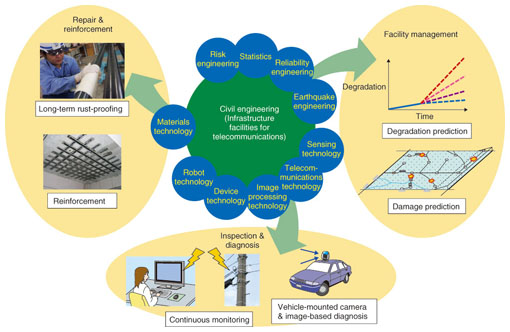

2.1 Facility-specific management techniques based on prediction of degradation and damageThe plan used to manage the entire maintenance and management cycle is based on facility management criteria such as inspection interval, inspection items, confirmation of degradation, and the timing of repair and reinforcement work. However, most of those criteria were set with reference to general structures that existed at the time the telecommunication infrastructure facilities were constructed, a time when awareness of maintenance and management was relatively low. The criteria are even ambiguous as a basis for engineering. The NTT Access Network Service Systems Laboratories is proceeding with R&D on facilities management technology for revising such management criteria for NTT facilities to match current maintenance needs. For example, even for facilities that were constructed with specifications that are nationally uniform, the degree of deterioration from aging, the earthquake damage rate, and the impact of facility failure can all vary with the facility environment. Our objective, therefore, is to create a more efficient maintenance and management cycle achieved by using detailed criteria that take the conditions of individual facilities into account instead of using uniform criteria for all facilities. Achieving that objective requires technology for evaluating the states of individual facilities and for predicting degradation and damage. Such predictions can be made by understanding the mechanism of deterioration with age, identifying points that are weak against earthquake damage, and analyzing the enormous amount of accumulated inspection data. Doing so would make it possible to set priorities and optimize timing for facility inspection, repair, and implementation of earthquake countermeasures. It would also become possible to examine the inspection items and procedures for each facility in more detail. When all facilities are new, the total repair cost can be effectively held down by considering the life cycle cost and inspecting all of the facilities uniformly, and by repairing facilities whenever slight degradation was found. However, under conditions where all facilities are aging, such as the conditions that exist now, facilities management must consider the risk of facility failure as well as the total repair cost. The objective of the NTT Access Network Service Systems Laboratories is to establish a management method that takes the probability of facility failure and the effects of a failure into consideration [1] [2]. 2.2 Inspection and diagnosis automation with images and sensorsThe aspect of maintenance and management that most requires skilled technicians is facility inspection. Inspection is difficult because the number of facilities is immense, facilities are spread widely across the country, and they are installed under roads and on bridges. With the declining number of skilled technicians, inspection has become the primary cause of delays in the maintenance and management cycle. Also, the ceiling collapse in the Sasago Tunnel spurred a move toward stricter inspection of the nation’s facilities. As a result, NTT business companies now regard improvement of inspection efficiency and quality as the most important problem in terms of maintenance and management. We are working on ways to solve that problem by developing technology for automating the inspection work that is now performed using human vision and touch. This technology includes the use of image processing, sensors, and robots. In addition to the obvious objective of higher efficiency, we are also targeting inspection results that are more accurate without depending on the skill of the technician, inspection of parts that cannot be seen by human inspectors, and diagnosis of facility soundness using ways that cannot be done by human inspectors. Inspection automation can also effectively increase worker safety by reducing the work done by humans at dangerous sites such as on roadways or in high places. On the other hand, however, simply automating the work will not lead to a radical solution from the viewpoint of efficiency. Achieving efficiency of maintenance and management cycles more quickly requires inspection by using facility screening as well as inspection technology that is suited to screening. Rather than carrying out detailed inspections of the huge number of facilities one by one, we can analyze data collected from sensors installed in facilities and image data from vehicle-mounted cameras in order to identify facilities that should be thoroughly inspected. Doing so can avoid risk and greatly reduce the number of inspections that take place. While moving forward with this R&D, we are also looking towards the future challenge of realizing technology for ‘unconscious inspection’ by continuous monitoring, in which the facilities themselves transmit data [3]. 2.3 Economical repair and reinforcement technology for extending service lifeNTT’s basic stance is to extend the service life of aged telecommunication infrastructure facilities without having to renovate them. To more economically perform the increasing amount of repair and reinforcement work, and to extend the service life of facilities, we are moving forward with R&D on technology that takes the special features of NTT facilities into consideration. Examples include technology for repairing conduit with telecommunication cable in place and without interrupting service, and methods for accurately determining age deterioration, weak points susceptible to earthquake damage, and the residual strength of each facility part by part so that repairs can be completed with the minimum necessary local reinforcement. Another objective is to ultimately break free from the maintenance and management cycle itself by taking measures to control degradation when repair and reinforcement work is done and achieve maintenance-free facilities that have a perpetual service life. Although there is currently very little construction of new conduit and manholes, it is assumed that the relocation work will increase when age-deteriorated roads and bridges attached to NTT conduit and manholes are repaired or renovated. To reduce the cost of any new construction that is required, we are also investigating facilities for which there is no concern for age deterioration and which require no inspection, and simple, economical facilities that are limited to optical cables, with a view to the future all-optical network [4] [5]. 3. Future developmentTelecommunication infrastructure facility construction technology has developed around what is known as civil engineering technology. However, the maintenance and management technology described in this article essentially requires certain application technologies from other fields as well as combined use of various technologies. Those fields include materials technology, device technology, image processing technology, and wireless and other telecommunication technology, as shown in Fig. 3. In that respect, a major strength of the NTT laboratories is the advanced research in diverse fields centered around telecommunications technology. The NTT Access Network Service Systems Laboratories is proceeding with R&D in cooperation with the NTT Energy and Environment Systems Laboratories, NTT Device Technology Laboratories, and NTT Media Intelligence Laboratories. We will aim for innovative technology by further strengthening and expanding this cooperation between laboratories and applying the strengths of the NTT laboratories in our future work. Beyond NTT R&D, we are also aiming for technology that can be applied to facilities around the world and the development of new services and business opportunities that apply that technology. We will work to achieve those goals by deepening cooperation with universities and other sources of expertise and exchanging ideas with other infrastructure enterprises that face the same problems, while making continued efforts to extend our knowledge of industrial fields other than those related to infrastructure. Currently, aging and the lack of resistance to earthquake damage are important problems for social infrastructure facilities, including NTT facilities. The NTT laboratories will address that problem head-on and continue to conduct R&D that can contribute to society in general as well as meet the expectations of NTT business companies and NTT Group companies.

References

|

|||||||||||