|

|||||||||||||||||||||||

|

|

|||||||||||||||||||||||

|

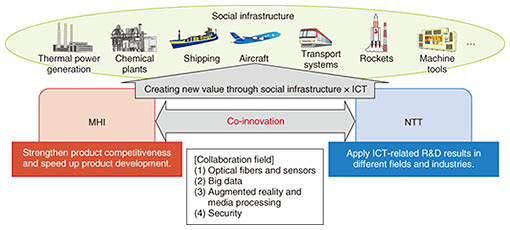

Feature Articles: New Value Creation through Collaboration with B2B2X Partners Vol. 17, No. 1, pp. 5–10, Jan. 2019. https://doi.org/10.53829/ntr201901fa2 Creation of New Value in Collaboration with Mitsubishi Heavy IndustriesAbstractIn collaboration with partner companies and organizations, the NTT Group is accelerating its efforts to promote the B2B2X (business-to-business-to-X) business model and thereby support the digital transformation of our corporate customers. This article describes a collaboration between NTT and our partner company Mitsubishi Heavy Industries, Ltd. (MHI). In particular, it explains how we are applying the results of research and development (R&D) done by the NTT laboratories in the information and communication technology (ICT) field to MHI’s social infrastructure products such as those for the energy and environment fields and the transportation and shipping industries and also to MHI’s factories and work sites in Japan and abroad. This partnership is aimed at rapidly creating new value through social infrastructure × ICT and utilizing R&D results in solutions to solve our customers’ problems as well as social problems. Keywords: digital transformation, photonic-crystal optical fiber, security technology for industrial control systems 1. Research and development collaboration on social infrastructure × ICTWith the joint aim of creating new value by integrating social infrastructure and information and communication technology (ICT), NTT and Mitsubishi Heavy Industries, Ltd. (MHI hereafter) started collaborating in April 2014 on research and development (R&D) focused on the following three themes (Fig. 1) [1].

Studies are underway on the applicability of NTT’s optical-fiber and laser technology and radiowave measurement technology cultivated in the field of telecommunications as well as biometric-information measurement technology to maintenance operations and manufacturing sites of MHI’s products. Field (2): big dataThe two companies are examining the applicability of NTT’s big-data processing and analysis technology to MHI’s big data such as operational statuses of products and customers’ opinions recorded at call centers. Field (3): augmented reality and media processingA study is being done on the applicability of NTT’s augmented reality technology and media processing technology such as video and audio to improve remote communication and work efficiency between support staff and workers at MHI’s domestic and overseas factories as well as at construction sites. The security field was added in March 2016 as a fourth theme. Thus, as of September 1, 2018, we have been working on new initiatives with MHI in four collaboration fields. Field (4): securitySecurity technologies for industrial control systems—combining control technology attaining high reliability and safety cultivated by MHI in the defense and space fields and NTT’s state-of-the-art security technology—are being investigated. This article introduces two collaborations. The first involves collaboration on R&D in the optical fiber and sensor field. Specifically, we introduce our R&D efforts concerning technology enabling transmission of a high-power single-mode laser beam over a longer distance, which was once considered impossible in the industry, while maintaining transmission quality suitable for laser processing [2]. This is enabled by fusing NTT’s optical fiber technology and MHI’s high-power laser processing technology. The second collaboration is in the security field. We introduce the cybersecurity technology called InteRSePT®*1 for industrial control systems and outline our efforts to commercialize it [3–5].

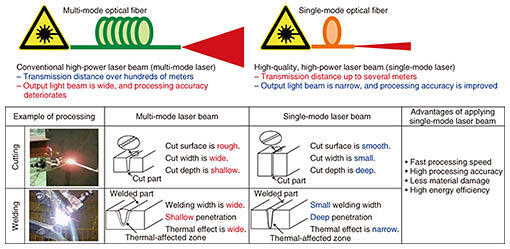

2. Collaborative research on optical fiber technology for transmitting high-quality laser beam processingOptical fiber is an essential part of today’s information and communication networks and is in wide use throughout the world. Applications of optical fiber range from endoscopes and gyros to transmission of laser beams for processing. With laser processing, it is necessary to transmit high-power laser beams with an output power more than 10,000 times stronger than that of the light used for normal optical communications. However, a nonlinear optical phenomenon imposes physical limits on the optical output and the distance that light can be transmitted by the optical fiber. The current widely used laser beam (multi-mode laser beam) can be transmitted over several hundred meters by using existing optical fiber (multi-mode optical fiber). However, the multi-mode laser beam has been unsuitable for applications requiring higher processing accuracy. Meanwhile, a high-power (10-kW class) laser beam (single-mode laser beam) suitable for more precise laser processing can only be transmitted several meters with existing optical fiber (single-mode optical fiber). Therefore, it is not suitable for application to actual laser processing requiring optical fiber transmission of several dozen meters (Fig. 2).

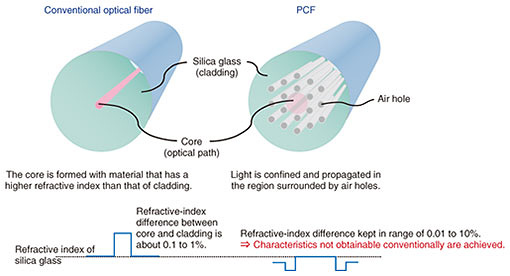

Photonic-crystal optical fiber (PCF: photonic crystal fiber)*2 [6, 7] technology previously developed by NTT was used in this collaborative research. In this technology, the light is confined to a region surrounded by an array of air holes and then propagated. NTT designed and developed a novel PCF optimized for transmission of a high-power single-mode laser beam, and NTT and MHI jointly demonstrated its high-power transmission capability [8] (Fig. 3). The results of this research were reported at the 89th Lecture Meeting of the Japan Laser Processing Society [9] held at Osaka University on May 23 and 24, 2018.

This technology can be applied to remote processing, remote welding, and thick plate cutting in the manufacture of existing automobiles, aircraft, and ships. It is also expected to contribute to expanding the application field of laser processing technology to various social infrastructure industries and thereby dynamically change the concept of manufacturing. While MHI continues to develop application technology for punching and welding of heat-resistant alloys, it aims to put this laser processing technology using PCF into practical use starting in 2019. In addition to developing optical fibers, we will promote collaborative R&D on potassium tantalate niobate (KTN: KTa1-xNbxO3) deflection elements and diffractive optical elements as basic technologies necessary for laser processing.

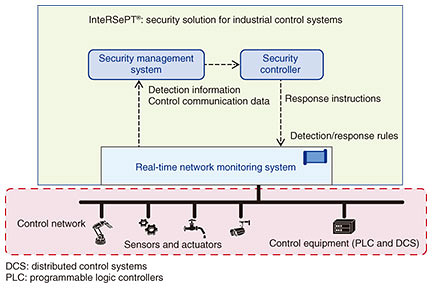

3. Cybersecurity technology for industrial control systems and efforts toward commercializationCybersecurity for industrial control systems is an important area requiring continued research. We report some key issues concerning cybersecurity for industrial control systems in this section. 3.1 Problems facing security of industrial control systemsAs the era of the Internet of Things progresses, the threat of cyber-attacks on industrial control systems of critical infrastructures such as factory facilities and electric power systems is ever increasing. Critical infrastructures such as factories, power/energy systems, and transportation systems consist of both information systems and industrial control systems. As mentioned above, ensuring the security of industrial control systems is just as important as ensuring the security of information systems. The following challenges arise with industrial control systems that need to be addressed with certain countermeasures. 1) Handling problems without causing frequent stops: Since factory equipment and power-system facilities cannot be stopped easily, it is difficult to handle problems (such as application of security patches) involving stops and restarts like those commonly carried out for information systems. 2) Handling long-term renewal cycle of industrial control system equipment: The renewal cycle of industrial control system equipment can cover long periods of more than ten years. Meanwhile, the supported period of information system equipment is often shorter than that and does not match the renewal cycle of industrial control system equipment. Moreover, it often happens that new equipment and old equipment are used at the same time. 3) Handling real-time control: Delays in exchanging control signals may be directly related to a control malfunction, and any transmission delays must be smaller than the allowable level. 4) Lack of security engineers: Since security is often managed by departments other than the information systems department, and there tends to be less distribution of security know-how related to industrial control systems, there is often a shortage of engineers familiar with the security of industrial control systems. 3.2 Concept of InteRSePT®In response to the four issues described above, MHI and NTT have developed a security solution for industrial control systems called InteRSePT®. InteRSePT consists of a security management system that monitors and responds to threats in an integrated manner and a real-time network monitoring system that detects unauthorized communications flowing through the network and implements interruptions of packets and other security measures as necessary (Fig. 4).

The function of each component is summarized below.

By carrying out this security processing on the InteRSePT side, we are providing the following solutions to the above-mentioned problems. 1) Downtime caused by the updates required for security measures is minimized. 2) Since the facility equipment (sensor and control equipment), which is the endpoint of the industrial control system, is not modified, the effect of security updates on the update cycle of the equipment can be minimized. 3) Equipment that can handle high-speed processing with low delay is adopted, and real-time control is supported. 4) It is possible to reduce the burden of security measures on engineers in charge of the industrial control system. 3.3 Expansion of InteRSePTThe NTT Group and MHI are currently collaborating on sales of security solutions using InteRSePT. Furthermore, we aim to respond to various requirements of industrial control systems and are therefore planning to strengthen InteRSePT as outlined below.

4. Future developmentIn the future, we will continue to create technologies that will help solve common problems concerning social infrastructure through collaboration between NTT and MHI as well as through new research efforts. Moreover, we aim to apply developed technologies in various industries by promoting collaboration with MHI along with the NTT operating companies. We also plan to share acquired knowledge within the NTT Group. References

Trademark notesAll brand names, product names, and company/organization names that appear in this article are trademarks or registered trademarks of their respective owners. |

|||||||||||||||||||||||