|

|||||||

|

|

|||||||

|

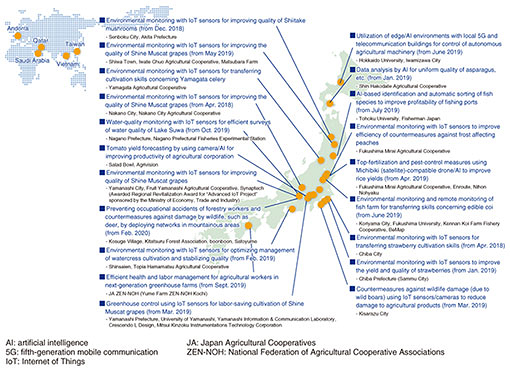

Feature Articles: NTT Group’s Initiatives in Food and Agriculture Vol. 18, No. 6, pp. 33–39, June 2020. https://doi.org/10.53829/ntr202006fa5 Community Revitalization by Utilizing ICT and AgricultureAbstractNTT AgriTechnology is the only agricultural company in the NTT Group and is implementing advanced technology in the food and agriculture supply chain as an agricultural-production corporation. In cooperation with domestic and overseas producers, Japan Agricultural Cooperatives (JA), local governments, the National Agriculture and Food Research Organization, agricultural-related companies, and other organizations, we are creating a new form of agriculture, which is a major industry in rural Japan, by operating a large-scale greenhouse using the latest technology. Our dedicated efforts to promote profitable agriculture as well as develop communities and nurture human resources through the food and agriculture business are introduced in this article. Keywords: high-tech greenhouse, data-driven horticulture, food value chain 1. Projects that spread nationwideThanks to being the sole agricultural corporation of the NTT Group, NTT AgriTechnology is receiving inquiries from both domestic and overseas producers, all types of businesses, and NTT Group companies [1–3]. We believe that food and agriculture are the backbone of our society and a major industry that supports the Japanese regional economy and community. Against this backdrop, an increasing number of producers and regions are practicing profitable agriculture to address issues such as a declining birthrate, aging population, improving productivity, and adding value (i.e., increasing income) (Fig. 1).

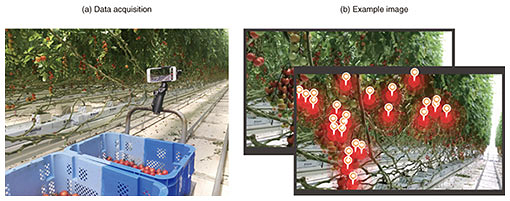

When it comes to agriculture, we tend to focus on production sites. However, it is important to accurately grasp the flow of information from production to consumption and manage the agriculture process on the basis of that information while adding value at each point such as distribution, processing, and sales. In this process, when information (data) is connected and forms a circle, that is, when it functions as a food value chain, many things become possible. The projects introduced in this article are not examples of individual solutions; on the contrary, they are all organically connected. We are responding to social needs through our efforts of effectively using our three approaches, “value chain from production to sales,” “large-scale to small-medium-scale farmers,” and “demonstration to implementation.” 2. Initiatives with Salad Bowl GroupSalad Bowl has attracted attention as a pioneering agricultural corporation. AgriVision, a group company of Salad Bowl, produces and sells high-quality tomatoes cultivated in a vast greenhouse covering about 3 ha by using advanced technologies such as automatic environmental control. The bottleneck in that process is the fluctuation in yield prediction. Up until now, yield predictions depended on grower’s observations and empirical rules, so there was fluctuation between each grower in charge at a particular time. To solve this problem, we developed and introduced a yield-prediction system. With this system, a smartphone is fixed on a trolley used for harvesting work, the tomatoes to be harvested are photographed, and the images are stored on the cloud via an optical fiber line connected to Wi-Fi in the greenhouse. The data are used to analyze the color, size, and number of tomatoes, select those that are ready for harvesting the next day, and predict the yield (Figs. 2(a), (b)).

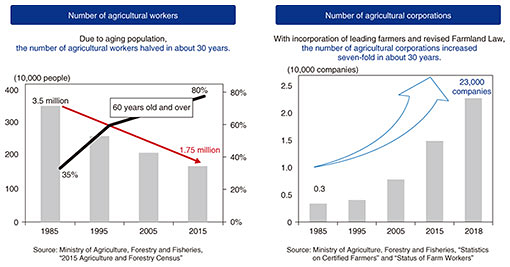

The predicted (i.e., calculated) yield is then used for suitable allocation of harvesting and packing workers for the next day’s work, arranging logistics trucks, and providing information to buyers. This initiative represents the first place to connect the value chain from the field to the shipping destination and customers. This system will greatly reduce shipment adjustments, opportunity loss, and food loss due to sudden out-of-stock items and excess items on the day. By connecting the food value chain in this manner, it becomes possible to deliver high-quality agricultural products to more people while maintaining freshness and reach more consumers. As a result, we can create more profitable agriculture. 3. Initiatives with ZEN-NOHWhile the number of farmers is decreasing due to the declining birthrate and aging population in Japan, agricultural management is becoming larger scale and more incorporated (Fig. 3). Under these circumstances, the importance of labor management will increase along with that of securing human resources, especially during the transition from family management to corporate-organization management. In agriculture, job sharing and acceptance of foreign technical interns are increasing. Moreover, a recent trend is to have disabled people play an active part through cooperating with social welfare organizations. We are in an era that necessitates an environment for accepting diverse workers and flexible working practices to secure human resources, and agriculture is no exception. It is therefore important to ensure the health and safety of farm workers through proper communication and formulate and review work plans, suitably allocate workers, and manage labor through standardization of work, etc. Therefore, working in cooperation with the National Federation of Agricultural Cooperative Associations (ZEN-NOH) at a large-scale greenhouse facility called Yume Farm ZEN-NOH NEXT Kochi operated by ZEN-NOH in cooperation with local Japan Agricultural Cooperatives (JA) bodies, local governments, and producers, we launched a project that implements safe, secure, and efficient agricultural management through health and labor management of farm workers by using Internet of Things (IoT).

In this project, we started off with an effort to protect the health of workers as well as the acceptance of technical interns from Vietnam. Vital data (heart rate, etc.) of the farm workers are acquired via a wristwatch-type wearable device, and those data are combined with the data acquired from temperature and humidity sensors installed in greenhouses for environmental control. The data are used to visualize the effects of workload on the body, and if preset conditions for such effects are exceeded, an alert is sent to the administrator of the farm. Even if a foreign worker or disabled person has a communication problem, the administrator can encourage them to take a break (Fig. 4).

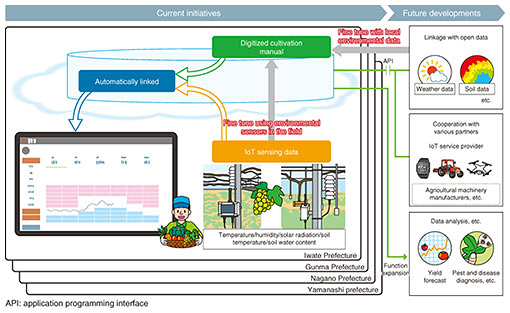

Combining location information with such data makes it possible to fully understand the work content and working hours of each farm worker; consequently, it will be possible to improve the work environment (review work-flow lines, etc.) and manage labor to achieve, for example, appropriate staffing. We aim to implement this scheme in each region where securing a sufficient number of workers is an issue by cooperating with ZEN-NOH, which is deeply involved in such regions and supports producers. 4. Collaboration with National Agriculture and Food Research OrganizationAs the number of agricultural workers decreases, interest in smart agriculture for saving labor and improving productivity is increasing. The Japanese government has also declared the goal of “almost all agricultural workers will practice data-driven agriculture by 2025” (Integrated Innovation Strategy 2019). To implement agriculture using data, a system that benefits producers and local communities is required. For example, we received feedback from producers who expect a system that can stably produce high-price agricultural products and new competitive varieties without relying on experience. Therefore, income increases and local governments can expect a system that can maintain and grow agriculture as a sustainable industry by passing down technology for cultivating agricultural products and improving brand power. Under these circumstances, with the aim of improving agricultural productivity and income of producers, we signed a collaboration agreement with the National Agriculture and Food Research Organization (NARO) to promote regional implementation of data-driven agriculture. As the first step, we will cooperate with NARO and public agricultural testing and research centers to digitize the paper-based cultivation manuals currently owned by both parties and store them in the cloud. We will also provide a mechanism for automatically linking the digitized cultivation manuals and the environmental data (temperature, etc.) acquired from the IoT sensing devices installed in the field. As a result, growers with little experience in cultivation can effectively obtain information and learn cultivation methods that enable optimal management of fields. For example, we will support the stable production by producers who have newly entered into the agriculture business and those who are new to the cultivation of high-added-value varieties. In addition, temperature and other standards required for optimal management of field environments for each region and type of agricultural product will be automatically displayed on terminals such as tablets for producers. This information can be used easily without any specialized knowledge of information and communication technology (ICT), so data-driven agriculture will become familiar in many regions. Digitized cultivation manuals facilitate the transfer of technology and are expected to help maintain and grow agriculture as a sustainable regional industry. By incorporating environmental data accumulated from IoT sensing devices installed in the field and open data, such as weather data, in the digitized cultivation manuals, it will be possible to improve brands and enhance added value of all production regions (Fig. 5).

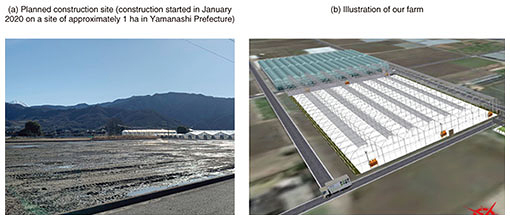

5. Production and sales through high-tech greenhouse farming by NTT AgriTechnologyTo demonstrate technology that effectively adapts techniques to the unique environment of Japan and demonstrate agricultural management that attains high productivity and practices profitable agriculture, we will establish our high-tech greenhouse facility to produce and sell the products that will be cultivated there. Before the start of the construction of our greenhouse, we conducted technical research in various countries, mainly in Europe, and repeatedly discussed greenhouse design suitable to Japan’s environment for several months. As a result, a very high strategic nature is reflected in our greenhouse. Automation through mechanization is essential to achieve high productivity. However, automation cannot be effective unless it works properly in a series of production activities. Therefore, we first determine the sales destination and market. On the basis of the determined needs, we then decide the final shipment form of the production item, set target values for size and shipping amount of one packaged product, and calculate the required daily production. After that, we specifically trace back to intermediate management (such as harvesting, irrigation, and spraying), planting, raising seedlings, germination, and sowing, and calculate the amount of work and required space for each process. Through simulating production activities, we can thoroughly identify bottlenecks and preferentially mechanize such activities to improve the overall process flow. After confirming that significant effects can be anticipated, we will select automation equipment and robots to be introduced. Some of this equipment will be introduced in Japan for the first time. By introducing such equipment, we expect cultivation efficiency to increase 50% and the number of workers to be halved. As a producer ourselves, by quantitatively demonstrating the effects of introducing technology and improving return on investment, we will gain the ability to provide producers around the world with confidence and certainty (Figs. 6(a), (b)).

6. Future developmentsAccording to the way the word “agricultural-community culture” is used in Japan, agriculture is closely related to community and human-resource development. When it comes to smart agriculture, we tend to focus on using ICT at production sites. However, this is not what we are aiming for. The role that we should play is to be involved in community development. Agriculture is an important industry that can serve as a starting point of community development. Inquiries from some local governments revealed that they want to rejuvenate their regions by providing an ecosystem to producers. That is, centered around agriculture, they want to create a food cluster of related industries such as physical distribution, warehouses, energy, processing, and environments necessary for workers (daycare centers, etc.). We cannot make half-hearted effort to meet their expectations. The projects described above will take several years to complete. Even so, we are committed to responding to local sentiment. We aim for highly productive agriculture in Japan, which has been negatively affected by an aging society with a low birthrate, to reach a high enough level to help the world’s agriculture cope with future explosive population growth. References

Authors (clockwise from top left): Taiga Sakai, Chief Executive Officer, NTT AgriTechnology; Daiki Endo, Senior Vice President & Chief Technology Officer, NTT AgriTechnology; Shingo Maehara, Senior Vice President & Chief Financial Officer, NTT AgriTechnology; and Masaki Hiizumi, Senior Vice President & Own Farm Director, NTT AgriTechnology |

|||||||