|

|||

|

|

|||

|

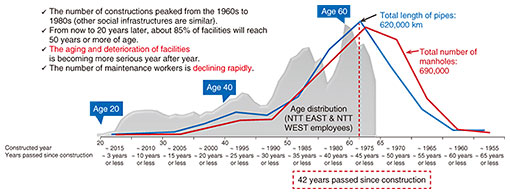

Feature Articles: Keynote Speeches/Workshop Lectures at Tsukuba Forum 2020 ONLINE Vol. 19, No. 4, pp. 30–35, Apr. 2021. https://doi.org/10.53829/ntr202104fa3  Activities Centered Around the Smart Infrastructure PlatformAbstractThe Smart Infrastructure (Smart Infra) Platform is a project NTT Infrastructure Network Corporation is advancing for improving the efficiency of infrastructure-facility work through digital transformation. We are developing digital twins that will provide high-accuracy position information (absolute position) of infrastructure facilities buried underground. By sharing digital information among infrastructure providers, we seek to implement a model in which tasks being done by workers to date are digitized and manpower is shared by unifying similar tasks. We are also aiming to add digital twins of aboveground facilities and expand the Smart Infra Platform to other fields such as disaster prevention/mitigation and smart cities. This article is based on a workshop lecture video-streamed on the Tsukuba Forum 2020 ONLINE website in October/November 2020. Keywords: infrastructure facilities, digital transformation, 3D spatial information 1. Background of activitiesChanging society structurally by making it “smart” has become necessary when it comes to infrastructure work. This is because in addition to the aging of infrastructure facilities and decline in the number of technical workers, we must also take into consideration how work will be carried out in the COVID-19/post-COVID-19 era. Forty to sixty years have passed since the peak of infrastructure-facility construction by the NTT Group. The average age of workers has also increased, as can be seen from their age distribution (Fig. 1).

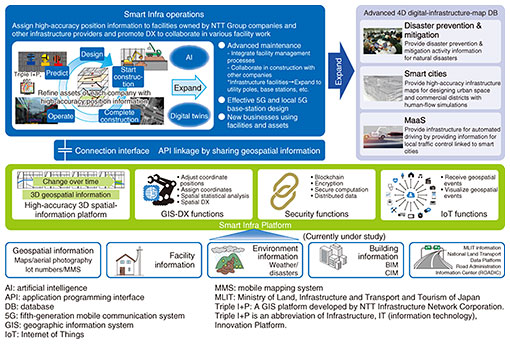

We believe that we can respond to these social challenges by advancing digital transformation (DX) of the infrastructure business, improving work efficiency by leveraging a wide range of digital data through data sharing. We are also pursuing sharing manpower and technologies to further improve efficiency. 2. Concept of Smart InfraThe Smart Infrastructure (Smart Infra) concept (Fig. 2), which NTT Infrastructure Network Corporation is advocating, involves developing a system that digitizes the locations/positions and conditions of infrastructure facilities by using high-accuracy position information that can be shared. By enabling the information to be visualized, skill-less work can be promoted and tasks for different types of infrastructure, such as telecommunications, power, and gas utility facilities, can be unified.

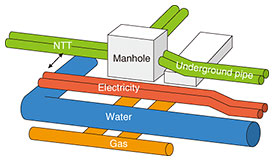

Looking toward the future, we want to make it possible to predict the conditions of underground facilities and take optimal actions. Specifically, we are developing a system in which highly accurate three-dimensional (3D) positions based on high-accuracy 3D spatial information are assigned to facility data owned by infrastructure providers, enabling the information on facilities to be shared. We are also developing an environment that enables machine processing to render information pictured in a person’s mind as 3D visualizations, allowing design, construction, and maintenance to be carried out efficiently. Sharing 3D facility information among infrastructure providers will also promote work sharing, thus improving efficiency. The Smart Infra Platform applies not only to underground infrastructure but can be expanded to existing aboveground infrastructure facilities. We wish to contribute to growing the NTT Group’s business by leveraging the Group’s 4D digital platformTM. This platform promotes linkages with external data, such as data in mobility fields such as mobility as a service (MaaS). It also links with smart-city and dynamic information, contributing to community-building and urban development through the distribution of building/construction information modeling, management (BIM/CIM) data. 3. Uses cases of the Smart Infra PlatformThe Smart Infra Platform is currently being used in the following four themes as use cases for improving the efficiency of the infrastructure business.

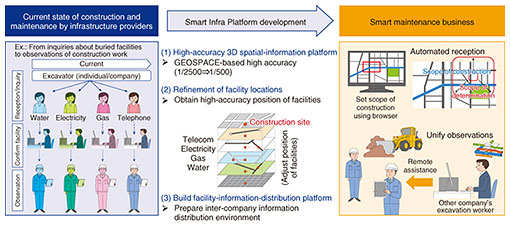

3.1 Initial use casesFrom inquiries about buried facilities to observations of construction work, each company currently handles cases in a disparate manner. Onsite observations are carried out as needed to confirm facility conditions and determine the impact of construction/excavation will have on nearby facilities. However, by using the Smart Infra Platform to assign high-accuracy position information and improve the accuracy of automatic estimations, it will be possible to identify on computers more cases that are determined as not impacting other facilities and services, thus reducing onsite observations. The labor required to confirm the impact on facilities by checking blueprints and other documents can also be reduced (Fig. 3).

When there is impact, we ask the company inquiring about a buried facility to visit us to have discussions about construction. In the future, it will be possible to carry out discussions remotely by using 3D virtual space (Fig. 4).

Regarding onsite observations, the Smart Infra Platform enables visualization of underground conditions. Even visualization of just NTT’s facilities contributes to predicting dangers and improving decision-making. Furthermore, tasks can be unified by observing telecommunications, power, and gas utility facilities at the same time. We plan to enable observations and construction instructions to be carried out remotely in a manner similar to remote discussions about construction (Fig. 5).

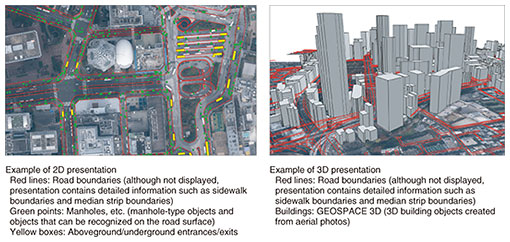

Joint construction efforts are currently being carried out between NTT and other companies. However, there are still many cases in which each company carries out work separately, such as repeatedly excavating and filling in roads, which lengthens construction time. If conditions of underground space can be shared in advance, preparations for joint construction can also be made proactively. This leads to greater rates of joint construction and reduction in construction costs and shortened construction time since work, such as facility excavation and road filling, can be kept to a minimum. Finally, a future plan is the prediction of facility deterioration. The conditions of facilities buried underground cannot be confirmed unless they are excavated. Therefore, there is no choice currently but to carry out maintenance only when a problem occurs. Preventive maintenance will be possible by predicting the future conditions of facilities based on soil and groundwater conditions. We plan to work on establishing efficient and effective maintenance plans based on predictions of facility deterioration. 3.2 High-accuracy 3D spatial informationRegarding 3D spatial information targeted for the infrastructure business, we are preparing data needed to align the locations and positions of infrastructure facilities. Specifically, we are preparing reference-position data on road boundaries (road edges, sidewalk edges—the boundary between a road and sidewalk, and median strips), utility holes (manholes and handholes), and underground entrances/exits to supplement a variety of data with position information and improve their accuracy. To use the data being prepared as position references, high-accuracy position data are required. We are therefore preparing data based on map information level 500* accuracy (deviation of ±25 cm in position) (Fig. 6).

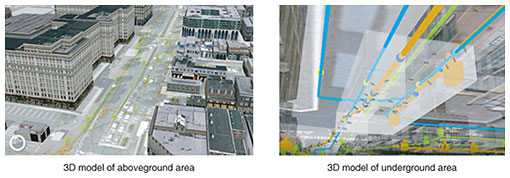

As a method of preparing data, we acquire information on the aforementioned road boundaries and utility holes by using high-resolution aerial photography with ground resolution of 5 cm. To prepare data on the 23 wards of central Tokyo, we manually convert aerial photos to stereo images and digitize them. We are also working on artificial intelligence (AI)-based automatic data acquisition by using the high-resolution 3D spatial information of the 23 wards we have prepared as training data. This is an initiative with significant hurdles. We are working with a variety of people, from venture companies to NTT Group companies and labs, to substantially reduce costs by automating tasks with AI. 3.3 Proof-of-concept demonstration with the Ministry of Land, Infrastructure, Transport and TourismIn fiscal year 2019, we consulted on a project with the Ministry of Land, Infrastructure, Transport and Tourism’s Kanto Regional Development Bureau. For this task, 3D models of aboveground and underground facilities in the Minato Mirai-Kannai area in Yokohama City were created to see how they could contribute to improving work efficiency and safety (Fig. 7).

The Tokyo Electric Power Company, Tokyo Gas, and the Yokohama City Waterworks Bureau provided data on buried facilities, which we converted to 3D data to create data on underground space. Each organization separately manages its blueprints and the position information contained within. As a result, there were cases in which integrating the data resulted in facilities overlapping positionally or being located in an impossible location in reality. These cases affirmed the importance of improving the accuracy of position information. Improving 3D images of underground space with more accurate position information will clarify positional relationships between facilities and clarify the extent of the impact their excavation will have. Value is thus produced in the resulting safe and efficient construction.

4. Future plansWe began our DX service for underground communication facilities in December 2020. We provide services from responding to buried facility inquires to automatic determination of the impact construction will have and visualization of underground space to support onsite observations. In fiscal year 2021, we plan to expand the range of NTT’s DX by expanding the preparation of high-accuracy 3D spatial information. We also plan to provide the functions we use for our DX to electric and gas utility companies for their DX. Regarding high-accuracy 3D spatial data for the 23 wards of central Tokyo, we have not yet been able to obtain data on roads under elevated structures. This is because we are using aerial photography. For spots that cannot be seen from above, it is necessary to carry out high-accuracy measurements on the ground by using the mobile mapping system (MMS). While aerial photography is effective in urban areas where roads are dense, data acquisition using MMS is more cost-effective in areas such as the suburbs, where roads are less dense. We are thus collaborating with NTT laboratories in conducting research and development of AI for MMS to gather and prepare data efficiently. We are also conducting research in MMS for switching to low-cost equipment while maintaining accuracy and quality. |

|||