|

|||||

|

|

|||||

|

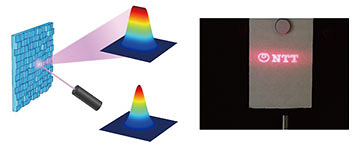

Feature Articles: Healthcare Devices and Infrastructure-maintenance Technology that Support People and Society Vol. 19, No. 6, pp. 61–65, June 2021. https://doi.org/10.53829/ntr202106fa9 Derusting Technology Using High-power Laser DeviceAbstractRust removal in narrow spaces that are inaccessible to human hands or electric tools is a challenge in derusting operations essential in prolonging the life of steel towers and other communication infrastructure facilities supporting communication services. We are developing technologies for efficient derusting using high-power laser devices developed by NTT. In this article, we introduce a compact and lightweight derusting technology incorporating a high-power laser device called a diffractive optical element. Keywords: high-power laser, derusting, diffractive optical elements 1. Issues surrounding derusting technologies for communication infrastructure facilitiesSteel towers and other communication infrastructure facilities are important in safely and securely providing communication services essential in modern life. Exposure to sunlight and weather elements deteriorates the strength of these facilities, which are not easy to replace. Therefore, they need to undergo regular inspection and repair to enable continued use over a long period. There are approximately 20,000 of these steel towers, including small ones, owned by the NTT Group across Japan. Most were built during the high-economic-growth period in the 1960s and 1970s and are now in an advanced state of deterioration; thus, costs and human resources needed for their inspection and repair have increased yearly. Reducing costs and labor is, therefore, critical in making future inspection and repair sustainable. NTT is currently developing various painting materials to control rusting, as well as technologies to test paint deterioration, predict corrosion of steel products, and remove rust. Prolonging the life of steel towers requires methods of controlling rusting as well as removing rust. Electric tools and metallic brushes are usually used in derusting, but it is difficult to remove rust from narrow spaces or around bolts. Sand blasting, a method with which sand particles are propelled at high speed onto surfaces, is one such method but is difficult to use because removing the sand takes time. Derusting tools using high-power lasers have, therefore, drawn attention. Commercially available rust removers using high-power lasers, however, have large and heavy handheld laser-emission heads, making it difficult to use by workers who have to climb steel towers to carry out derusting. We, therefore, developed an affordable, light-weight diffractive optical element (DOE) for a compact, lightweight, and field-friendly rust remover we are developing. 2. Technology of DOEs used in high-power lasersA DOE is a device that applies holographic techniques for phase modulation of incident light in substrate microstructures. It enables the transforming of the incident laser-beam into any desired shape, as shown in Fig. 1. This characteristic is exploited in metal and resin processing.

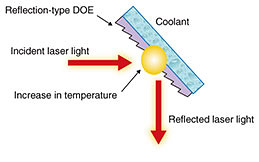

Figure 2 is a schematic diagram of the DOE we developed for high-power laser processing. To prevent the increase in temperature due to the absorption of laser light and the damage it causes, we used a silicon carbide substrate, which has high thermal conductivity, and designed a reflection-type device, which is easier to cool, making it possible to carry out laser processing at 10 kW [1]. This DOE is not only light at only a few grams but also simple in structure. We used this DOE to develop the compact and lightweight rust remover described below.

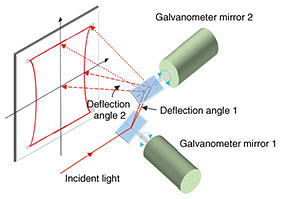

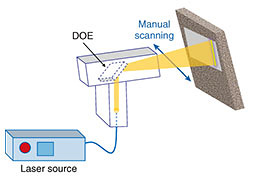

3. Rust remover that NTT is developingAs shown in Fig. 3, in commercially available rust removers using lasers, laser-beam scanning is carried out either one-dimensionally or two-dimensionally using a mirror and motor to enable workers to remove rust over a fixed surface area without moving their hands. The handheld laser-emission head, however, is large and weighs several kilograms, making it burdensome for the worker and difficult to use on steel towers. To address these issues, we developed the method shown in Fig. 4 for shaping light into a thin straight line using our DOE and carrying out manual scanning without the need for a motor. Derusting, therefore, can be carried out with the same efficiency as with the conventional method.

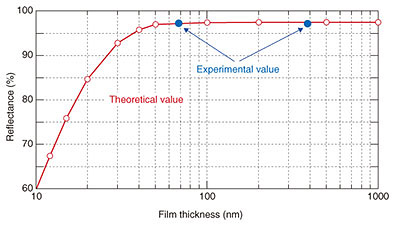

4. Towards affordable DOEsAs mentioned above, we used silicon carbide for DOEs in high-power lasers, but it is an expensive material. Due to the high likelihood that a DOE would become dirty or damaged during derusting, it is preferable to use more inexpensive DOEs. We, therefore, devised methods of replacing silicon carbide with less expensive materials to promote the use of rust removers that use DOEs. Silicon is a material for which micro-processing techniques are well established in the semiconductor industry. Aside from its relatively low cost, it is also easily available, making it an ideal substitute as an inexpensive material. However, due to absorption of light at a wavelength of 1.07 μm used in rust removal, there is risk of damage due to increase in temperature. Although reflectance can be increased by applying a metal film on the surface to minimize light absorption, a thicker coating would result in the rounding of the corners of the DOE surface’s microstructure, leading to errors in laser-beam shapes. In other words, it is critical to find the right metal with the proper thickness to achieve sufficient reflectance while reducing laser-beam-shape errors. We, therefore, considered gold, which has high reflectance and high thermal conductivity, as a coating material and calculated and measured the relationship between its film thickness and reflectance. As shown in Fig. 5, reflectance reaches its peak at 50-nm thickness. Therefore, we determined the optimum thickness that results in sufficiently low laser-beam-shape error at around 50 nm. We were able to achieve laser processing at 10 kW, which far exceeds the power needed for rust removal. This demonstrates that costs can be feasibly reduced by using silicon as the diffraction grating material [2].

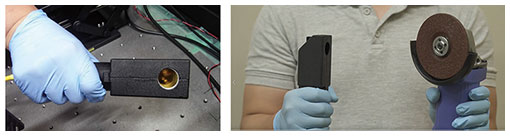

5. Development of a compact and easy-to-use rust removerFigure 6 shows a prototype of the laser-emission head of the rust remover we are developing. By using our DOE, we demonstrated the possibility of fabricating a laser-emission head that weighs only 500 g, which is not possible with commercially available devices. The laser head is as small as a conventional electric tool, and being light and easy to use, it has potential for widespread use in derusting. Figure 7 shows the results of an experiment to remove rust from narrow spaces that are difficult to reach with electric tools. Since laser light is used, there are no vibrations and restrictions in applicability inherent with electric tools, reducing the burden on workers.

These results indicate that using our DOE eliminates the need for motors, which are a limiting factor in the size and weight of commercially available devices, demonstrating the feasibility of using compact and lightweight rust removers for steel-tower cleaning. 6. Future prospectsAs mentioned in the introduction, prolonging the life of steel towers and other communication infrastructure facilities requires technologies for rust removal and for maintaining surface conditions that prevent paint from peeling off. The conditions needed in the irradiation of laser light affect surface conditions and the strength of paint adhesion. Therefore, research on the surface conditions after rust removal using laser and on-paint adhesion are crucial in prolonging the life of communication infrastructures. Going forward, we will continue to conduct research on these areas to create new value by developing rust removers that contribute to improving paint adhesion and are easy to use in the field. 7. ConclusionIn this article, we introduced the derusting technology we are developing to contribute to a sustainable society. We were able to reduce the cost of a device by replacing the silicon carbide of our DOE with silicon. We also resolved the problems associated with the size and weight of commercially available devices and demonstrated the feasibility of an affordable, compact, lightweight, and user-friendly rust remover. Going forward, we will conduct research on surface conditions to improve paint adhesion and create new value in infrastructure maintenance. References

|

|||||