|

|||||

|

|

|||||

|

Feature Articles: Access Network Technologies for IOWN Vol. 20, No. 9, pp. 21–26, Sept. 2022. https://doi.org/10.53829/ntr202209fa2 R&D Challenges in Solving Social-infrastructure ProblemsAbstractTo solve problems surrounding social-infrastructure projects, such as a declining workforce, proliferation of aging facilities, increasing maintenance and renewal costs, and frequent disasters, and to create a “smart world,” NTT Access Network Service Systems Laboratories is engaged in research and development centered on three pillars: (i) digital transformation of maintenance and operations, (ii) construction of safe and secure social-infrastructure facilities, and (iii) use of assets such as facilities and operations. In this article, the technologies related to these three pillars are introduced. Keywords: safe and secure social infrastructure, digital transformation (DX) of maintenance, use of communication infrastructure 1. Initiatives of the Civil Engineering ProjectAs well as facing a declining workforce, a rapid increase in aging facilities, and rising maintenance and renewal costs, the social-infrastructure industry must accommodate growing disaster risks due to climate change and seismic motion. To operate social-infrastructure facilities under these circumstances, it is urgent to address the following key issues: maintenance and operation that requires less manpower, renewal that optimizes the life-cycle cost (LCC), disaster prevention and mitigation, and reduction in environmental impact. The Civil Engineering Project of NTT Access Network Service Systems Laboratories will contribute to the creation of a “smart world” through their research and development (R&D) on the basis of three pillars: (i) digital transformation (DX) of maintenance and operations, (ii) construction of safe and secure social-infrastructure facilities, and (iii) use of assets such as facilities and operations (Fig. 1). In this article, the technologies that the Civil Engineering Project is developing—while aiming to create a smart world—are introduced.

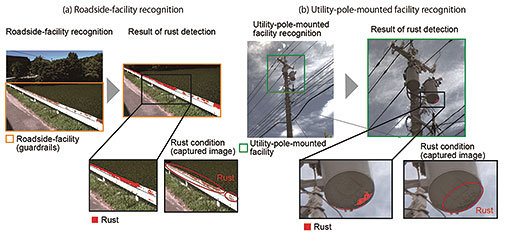

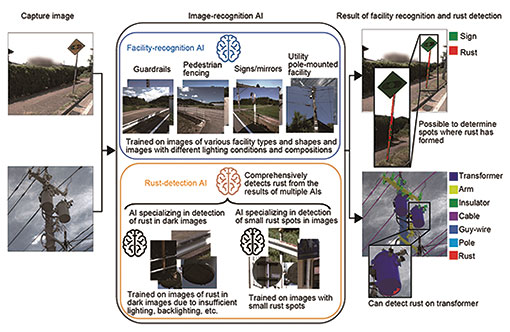

2. Technologies for creating a smart world2.1 DX of maintenance and operationsNTT uses a mobile mapping system (MMS) and drones to photograph outdoor communication facilities and uses the acquired images to check facility conditions and diagnose facility deterioration. We at the Civil Engineering Project have been researching and developing inspection and diagnosis technology for communication infrastructure and facilities using image recognition. Specifically, we have developed technologies using image-feature analysis and deep learning to automatically detect deterioration of manhole covers (i.e., surface wear and the gap between a manhole cover and the surrounding road) and rust on communication conduits attached to bridges. Although these technologies are used for diagnosing the condition of NTT’s facilities, the image-recognition technology must be further improved. We are currently researching and developing image-recognition technology that will contribute to the collaborative inspection of social infrastructure along roadsides. The goal with this technology is to (i) identify pixel areas of roadside structures, such as guardrails, and pole-mounted facilities, such as cables and metal fixtures, from multiple images of such roadside infrastructure facilities taken using MMS with image-recognition artificial intelligence (AI) and (ii) detect the pixel areas containing rust formed on the facilities (Fig. 2). To achieve this goal, the image-recognition AI incorporates multiple functions (Fig. 3). One function is facility-recognition AI, which can identify roadside infrastructure facilities with high accuracy by sufficiently learning the types of facilities that appear in various forms and compositions. Another function is rust-detection AI, which uses ensemble learning* [1] to detect minute amounts of rust in pixel areas on a pole-mounted facility and rust in pixel areas in dark areas of images taken under backlit conditions. Facility-recognition efficiency with this technology will be approximately 94% and rust-detection efficiency will be approximately 98%, which are sufficiently high for practical use.

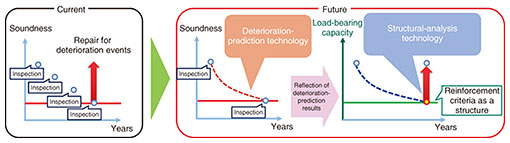

Implementation of the above image-recognition technology for collaborative inspections of roadside social infrastructure is expected to promote the centralization of on-site inspection work (which has conventionally been conducted by separate infrastructure operators) and improve the accuracy of facility diagnosis using AI. We now aim to improve the efficiency of the maintenance and management of social infrastructure by centrally managing facility information acquired during such inspections on a common platform. 2.2 Construction of safe and secure social-infrastructure facilities2.2.1 Technology for extending service life of structuresNTT maintains facilities in a variety of environments throughout Japan. We aim to establish technology for operating facilities to the load-bearing-capacity limit while ensuring safety by maintaining quality and optimizing operational resources, that is, maintaining the safety and reliability of a vast amount of facilities without using a large amount of manpower. Current inspections of infrastructure facilities and equipment are conducted at regular intervals while the inspection cycle is being optimized. To further improve the efficiency of inspection operation, we plan to establish a deterioration-prediction technology that can predict the future condition of facilities on the basis of deterioration phenomena and individual environments. This prediction is based on elucidating three factors: the materials that make up the facility, mechanism of deterioration in each installation environment, and rate of deterioration. The optimal inspection period for each facility will be determined using this deterioration-prediction technology; in other words, it will become possible to eliminate the need for periodic inspections. In the current infrastructure-facility repair process, when deterioration is confirmed during inspection, whether to repair is determined in accordance with the state of deterioration, any deterioration determined to be in need of repair is then repaired appropriately. To further reduce repair costs, it is necessary to shift from the current partial repair of deterioration to reinforcement based on an evaluation of the load-bearing capacity of the deteriorated structure. We plan to establish a structural-analysis technology for determining the future load-bearing-capacity limit of a structure by reflecting the future deterioration state of each facility through structural analysis and evaluating its load-bearing capacity. This structural-analysis technology will clarify the optimal reinforcement timing for the structure, enabling the facility to operate safely for a long period while optimizing the LCC (Fig. 4).

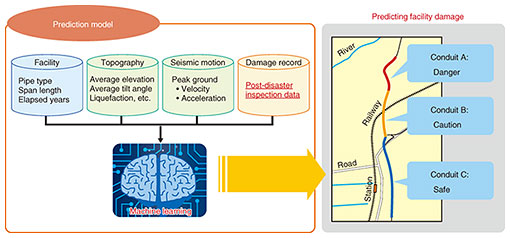

2.2.2 Damage prediction for infrastructure facilities due to seismic motionDuring the 2011 Great East Japan Earthquake in the Tohoku region of Japan and other major earthquakes, communication facilities were severely damaged by seismic motion and tsunamis. The Japanese government has announced assumptions concerning large-scale damage by possible earthquakes, such as a massive earthquake along the Nankai Trough or an earthquake directly under the Tokyo metropolitan area, and these assumptions will further increase the demand for the safety of facilities against earthquake damage. Communication-infrastructure facilities, such as service tunnels, manholes, and conduits, have been made highly resistant to earthquakes, including the Great East Japan Earthquake, thanks to the addition of seismic countermeasures (such as flexible joints) in the facilities. We have been researching and developing technologies that enable old-specification conduits to be seismically reinforced, without having to excavate roads and remove the cables, by using the new pipe-insertion type conduit system. We are currently researching and developing technology for predicting damage to individual conduits in the event of an earthquake. These predictions will enable us to identify conduits that require seismic reinforcement among the vast number of conduits that we maintain. We created a database for comparing a large number of parameters (such as facility information, topography and ground information, and seismic-motion information) regarding the damage caused by past large-scale earthquakes, identified the effective parameters for estimating damage through machine learning and variable-contribution analysis, and built an easy-to-use prediction model. The prediction model enables us to identify the locations of damage to individual conduits, which will enable us to take proactive measures such as planned countermeasures, prompt emergency inspections, and emergency repairs (Fig. 5).

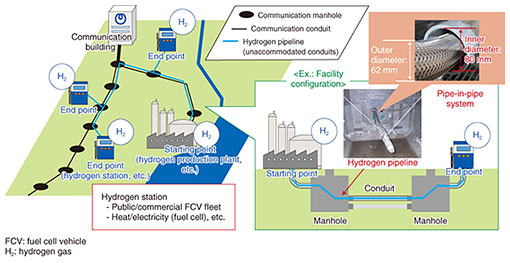

Through the above efforts, we confirmed that a prediction model that is machine-learned using information on facilities and the surrounding environment is an effective tool for predicting disaster damage. Although the content of the database used for machine learning will vary depending on the type of disaster, we believe that the technological approach (i.e., the developed prediction model based on machine learning) can be applied to various types of disaster prediction, and we will attempt to construct disaster-prediction models for disasters involving severe wind and flooding. We also believe that the model and technology can be extended to businesses operating “lifeline” facilities such as electricity, gas, and water and sewage systems. 2.3 Use of assets such as communication facilities and operationsSince the start of optical-communication services to general households in 2001, such services have rapidly spread, and current access networks are shifting from metal cables to optical-fiber cables. Compared with metal cables, optical-fiber ones are lighter and thinner, so they can be accommodated more efficiently, thus increase the space available in communication-infrastructure facilities. One example of effectively using this space is transportation of hydrogen via communication conduits, and we are verifying technologies related to this application. As a carbon-free energy that contributes to reducing energy-supply and procurement risks, hydrogen can be produced by electrolysis of water or reforming of biomass by using renewable energy. It is thus attracting attention as one of the next-generation energies for building a decarbonized society. Tanker trucks are currently the main means of transporting hydrogen; however, the challenge is to lower the cost of transportation and reduce emissions of carbon dioxide. One way to face this challenge is to use pipelines that use existing infrastructure. Transporting hydrogen by pipeline requires airtight transportation because the gas needs to be pumped under high pressure. Therefore, we are considering a pipe-in-pipe system in which an airtight pipeline for hydrogen transportation is accommodated in the existing communication conduit (Fig. 6). This system requires a flexible structure that enables the hydrogen-transportation pipeline to be laid within existing communication conduits and manholes. We are also evaluating safety in terms of hydrogen leakage and its impact on communication facilities as well as studying countermeasure technologies against such leakage.

3. Concluding remarksThe Civil Engineering Project is committed to developing technologies—including the initiatives described in this report—to create new social value by leveraging our assets: operational expertise, communication facilities, and communication technology. We will further promote the above R&D activities and contribute to solving issues faced by society as a whole by sharing our technology and expertise with facility-management companies facing similar challenges. Reference

|

|||||