|

|||||||||||||||||

|

|

|||||||||||||||||

|

Regular Articles Vol. 20, No. 10, pp. 77–81, Oct. 2022. https://doi.org/10.53829/ntr202210ra1 Development of a Rust Removal Tool Using a Diffractive Optical Element and High-power Laser and Its Application to Asbestos-melting ToolsAbstractTo improve the efficiency of rust removal on telecommunication towers, we developed a prototype of a compact, lightweight rust-removal tool using a diffractive optical element and high-power laser that weighs only 500 g. With the aim of applying this technology to asbestos removal, we experimentally irradiated asbestos with a laser, and the results of the experiment suggest that using a laser in this manner can melt and remove asbestos and reduce its risk as a health hazard to workers. Keywords: infrastructure, high-power laser, diffractive optical element 1. IntroductionNTT possesses a large amount and wide variety of infrastructure facilities that are indispensable for implementing NTT’s concept called the Innovative Optical Wireless Network (IOWN). To efficiently maintain these facilities, NTT is researching and developing technology that involves using high-power lasers and diffractive optical elements. In this article, a rust-removal tool using a high-power laser and diffractive optical element is described, and the results of experiments conducted to apply this technology to asbestos removal are presented. 2. Development of rust-removal toolNTT maintains 20,000 telecommunication towers, many of which are several decades old, so it is essential to remove rust from and repaint them to prevent them from deteriorating. Currently, electric tools are used to remove rust; however, the space around bolts is too tight for electric tools to remove the rust there. Lasers have been attracting attention as a means of removing rust. Lasers can melt and vaporize rust without contacting it, so rust can be removed from confined spaces without damaging the base material. However, a conventional laser system consists of a mechanical-drive unit that scans a laser beam (focused by a lens) in two dimensions, and the system is large and heavy, weighing about 2 kg, thus difficult to use high above the ground in places such as the upper reaches of telecommunication towers. Given the above-described circumstances, NTT aimed to develop a small, lightweight rust-removal tool that can be used high above the ground. We have developed a prototype rust-removal tool—weighing only 500 g—that can be held in one hand. We achieved this by eliminating the conventional mechanical-drive unit, which was replaced with a diffractive optical element for forming the laser beam with a narrow, linear intensity distribution and moving the shaped laser beam by hand [1]. The prototype laser system and examples of using it for removing rust are shown in Fig. 1. To prevent rust forming on steel towers, it is also important to prevent the paint from peeling off after the rust is removed. Accordingly, we confirmed that this technology (i.e., rust-removal tool) leaves sufficient paint adhesion to prevent rusting.

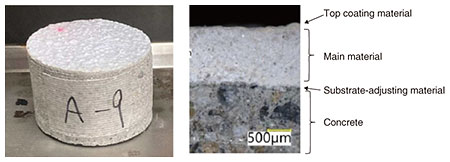

3. Application to asbestos removal3.1 Demand for asbestos removalSome of the facilities owned by NTT include buildings that contain asbestos, which must be removed when the building is demolished or renovated. However, there are several issues with methods of removing asbestos. We are therefore also researching the above technology to apply it to removing asbestos from buildings. Asbestos is a fibrous substance that has been produced and used in large quantities since the 1920s because of its excellent heat and chemical resistance. In the 1950s, however, asbestos was found to cause lung cancer, and its production and use were banned in Europe from the 1990s and in Japan in 2004 [2–5]. According to Japan’s Ministry of Land, Infrastructure, Transport and Tourism, the number of demolitions of buildings containing asbestos in Japan has increased and is estimated to reach 100,000 buildings around 2028. The demand for demolition work is estimated to continue for about 30 years [6]. Those buildings are being demolished after asbestos-containing painted materials are removed by using power tools or water jets. However, power tools invariably scatter asbestos, so equipment is needed to prevent leakage of asbestos and exposure of workers to it. If water jets are used, scattering of asbestos can be controlled, but it is difficult to remove asbestos from narrow spaces, and equipment for filtering water mixed with asbestos is essential. Asbestos-containing materials that have been removed are either melted down to eliminate its fiber structure and reused or disposed of as landfill. Owing to the above-mentioned increase in demolition work in the future, it is a concern that there will be the shortage of asbestos-treatment facilities and landfill sites. Asbestos-treatment technology that enables low-cost and efficient reuse is thus required [7]. We are researching and developing technology for reducing the risk of worker exposure to asbestos and leakage of asbestos by using high-power lasers to remove asbestos in a manner that melts it and destroys its harmful fibrous structure. High-power lasers can melt asbestos in a non-contact manner, so it becomes possible to remove asbestos in narrow spaces from which it cannot easily be removed with power tools or water jets. Hereafter, an experiment in which asbestos was melted by using a laser is described. 4. Asbestos-melting experiment4.1 Sample preparationChrysotile (Mg3SiO5(OH)4) powder, i.e., the most common form of asbestos, was used to confirm that laser melts asbestos. To observe the dust generated by laser irradiation of asbestos-based coating materials, coating materials collected from buildings were used in the experiment. The coating material consists of a base coat, main coating material, and top coat. Asbestos is used as the base-coat material when mixed with mortar. The appearance and cross section of an asbestos-containing coating material taken from a building and used in this experiment are shown in Fig. 2. The thickness of the base coat of the sample was about 50 µm, and the concentration of the asbestos (chrysotile) contained in the sample was 1 wt%.

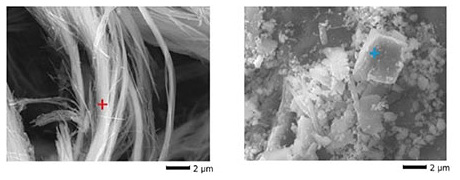

4.2 Laser-irradiation experimentA pulsed laser—with average output of 100 W, frequency of 100 kHz, and wavelength of 1.06 μm—was used. The laser beam emitted from the light source was focused using an fθ lens to spot diameters of 50 and 140 μm and scanned in two dimensions with a galvanometer mirror over an area of 8 × 8 mm. To qualitatively estimate the amount of asbestos dispersed by laser irradiation, the dust generated by laser irradiation was captured with a high-speed camera. It was assumed that the amount of asbestos dispersed was proportional to the amount of dust generated. The sample was illuminated using a laser with a wavelength of 532 nm and, simultaneously, a high-power laser with a wavelength of 1.06 μm. The light with the wavelength of 532 nm reflected by the dust was captured with the high-speed camera, and the amount of dust was qualitatively evaluated from the intensity of the reflected light. 4.3 Experimental resultsElectron micrographs of the chrysotile before and after laser irradiation are shown in Fig. 3. It is clear that the laser irradiation destroyed the fibrous structure of the chrysotile. Analysis of the composition of the particles observed after laser irradiation showed that particles containing magnesium and silicon were generated. Therefore, it is considered that the particles were the result of the chrysotile melting then solidifying.

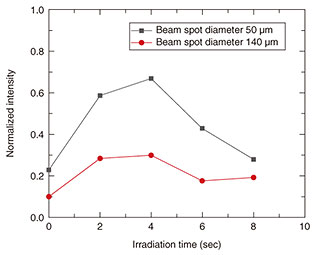

The results of qualitatively estimating the amount of dust on the coating material (collected from a building) when it was irradiated with the pulsed laser are plotted in Fig. 4. Images of the dust were captured with a high-speed camera, the brightness in the images was calculated, and the amount of dust was estimated from the calculated brightness.

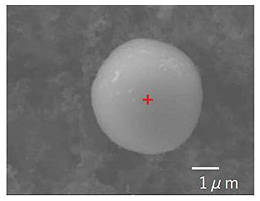

Since the brightness of the image changes by changing the beam diameter, it can be assumed that the amount of dust also changes. This suggests that the dust can be suppressed by appropriately controlling the laser-irradiation conditions. An example of one of the particles in the dust, as observed with an electron microscope, is shown in Fig. 5. Analysis of the composition of such particles showed that they contained magnesium and silicon, suggesting that the particles were the result of the chrysotile in the coating material melting and solidifying. It also suggests that irradiating asbestos with a laser can prevent it from being dispersed while it is still harmful. We believe that the use of a diffractive optical element in the manner described above can improve the efficiency of asbestos-removal operations.

5. SummaryA compact, lightweight rust-removal tool—weighing only 500 g—using a high-power laser and diffractive optical element was developed for efficiently removing rust from communication towers. We are researching the application of this tool to the removal of asbestos, which involves melting the asbestos during the demolition and renovation of asbestos-containing buildings. We conducted an experiment in which asbestos was irradiated with a high-power laser beam. The results of this experiment suggest that asbestos can be melted and asbestos dust can be suppressed by appropriately controlling the laser-irradiation conditions. References

|

|||||||||||||||||