|

|||||||||||||||||

|

|

|||||||||||||||||

|

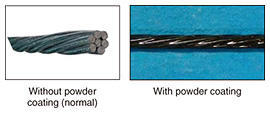

Practical Field Information about Telecommunication Technologies Vol. 22, No. 4, pp. 58–61, Apr. 2024. https://doi.org/10.53829/ntr202404pf1 Precautions for Installing and Repairing Powder-coated Messenger WiresAbstractThis article presents precautions to be taken when installing and repairing powder-coated messenger wires to prevent corrosion in salt- and sulfur-affected areas. This is the eighty-first article in a series on telecommunication technologies. Keywords: messenger wire, powder coating, corrosion protection 1. IntroductionNTT’s telecommunication equipment and facilities are installed throughout Japan in a variety of natural environments. The metals, concrete, and plastics used as materials for these facilities and equipment deteriorate over time due to effects from the surrounding environment, such as ultraviolet rays, rainwater, and seawater. Most outdoor metal equipment and facilities are hot-dip galvanized for corrosion protection. However, in severe natural environments, such as coastal areas that suffer salt damage (due to salt blown inland from the ocean) and hot-spring areas that suffer sulfur damage (due to the sulfur-rich air), the galvanization is severely degraded in a manner that rapidly exposes and corrodes the underlying metal to form red corrosion (highlighted by the red frame in Fig. 1).

To protect telecommunication equipment and facilities in such corrosive environments, applying a thick and durable powder coating (Fig. 2) over hot-dip galvanized equipment can extend the lifespan of the equipment, as described in the June 2022 issue of this journal [1].

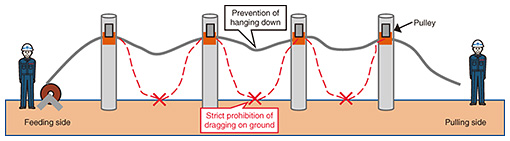

The powder-coating material developed by Technical Assistance and Support Center (TASC), NTT EAST adheres well to hot-dip-galvanized surfaces and is applicable to structures of various shapes. This article presents precautions to be taken when installing and repairing powder-coated messenger wires to prevent corrosion in salt- and sulfur-affected areas. 2. Precautions during design and installationPowder coating is a method of forming coating films by melting a powder at temperatures of approximately 250°C or higher at factories. As it is difficult to apply powder coating to installed equipment on site, equipment that has been powder coated is either repaired or newly installed. The following section presents precautions to be taken when designing and installing powder-coated messenger wires. 2.1 Precautions during designWhen a messenger wire is being newly installed, metal fixtures such as universal bands*1, dead-end grips*2, and suspension clamps*3 are also installed around the messenger wire. Most fixtures can be powder coated before use in the same manner as messenger wires. However, when designing the installation of messenger wires, it is important to avoid using components [2] such as messenger-wire crossing fixtures*4 that may put stress on the coating film and cause deterioration such as peeling. Since a powder-coated messenger wire has a larger diameter than a non-coated one, it cannot be fitted into a suspension clamp, so basically both ends of the wire are fixed to utility poles. However, the current messenger wire with minimum diameter (cross-sectional area of 30 mm2) can be fitted into suspension clamps. 2.2 Precautions during installationThe following precautions must be considered when installing powder-coated messenger wires on site. These precautions can be divided into those that focus on mechanical properties and those that focus on electrical properties. 2.2.1 Precautions focusing on mechanical propertiesWhen powder-coated messenger wires are installed, if the coating is peeled off by dragging on the ground or contact with an obstacle, deterioration will progress from that contact point. As shown in Fig. 3, to prevent peeling of the coating, a pulley should be installed at the messenger wire string point on each utility pole, and the tow rope should be pulled through the entire section to prevent dragging on the ground or coming in contact with obstacles due to loosening.

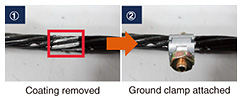

2.2.2 Precautions focusing on electrical propertiesA ground clamp and ground wire are attached to a messenger wire to ensure electrical safety. However, the powder coating on the messenger wire is made from an insulating resin, so it is not possible to establish conductivity with the wires under the coating simply by attaching a ground clamp. It is therefore necessary to remove the coating with a tool, such as pliers (recommended) or a wrench, and then attach the ground clamp to the exposed wire (Fig. 4). To lower the grounding resistance by connecting as many wires as possible, it is appropriate to install two ground clamps side by side.

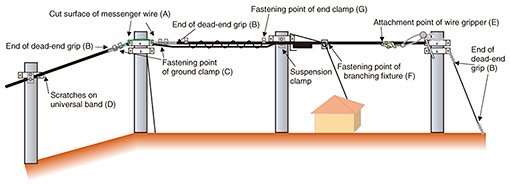

3. Precautions during repair3.1 Necessity of repair and repair materialsThe powder coating and hot-dip-galvanizing applied to messenger wires and surrounding fixtures can become scratched or peel off due to various factors during installation. Damage to the powder coating and galvanized plating will shorten the lifespan of the entire messenger wire, so it is necessary to repair the damaged area by using a method appropriate for the area to restore corrosion resistance. One repair method is to apply an anti-corrosion coating to the damaged area of the messenger wire. With on-site application of anti-corrosion coating, it is difficult to ensure an even distribution of coating thickness over long distances, and there is a risk of paint splattering, but it can be used as a localized repair method. Two types of coatings are available: liquid [3] and spray [4]. Although the liquid type has excellent corrosion resistance, it must be applied with a brush, so it is difficult to sufficiently apply it to confined spaces. For that reason, it is recommended to repair by applying the liquid type with a brush for open areas, such as the surface of messenger wires where no fixtures are attached, and by using the spray type in confined spaces, such as the fastening points of fixtures. 3.2 Precautions for each repair locationExample locations of repairs to a powder-coated messenger wire are shown in Fig. 5. The repair methods and precautions for each repair location are explained as follows.

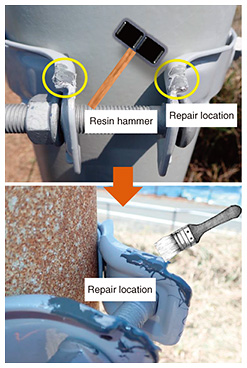

3.2.1 Cut surface of messenger wire and end of dead-end gripThe cut surface of messenger wire (Fig. 5(A)) and the end of the dead-end grip (Fig. 5(B)) are prone to damage to the coated and plated surfaces owing to impact during cutting and metal-to-metal contact. Since these locations are open areas and relatively easy to repair, repair by applying a liquid-type coating with a brush is recommended. 3.2.2 Fastening point of ground clampAs explained in Section 2.2.2, when a ground clamp (Fig. 5(C)) is attached to a messenger wire, the coating is removed with a tool such as pliers to ensure conductivity. After the ground clamp has been fastened, the area where the coating has been removed must be repaired to prevent corrosion. For confined spaces such as the gaps between clamps, where it is difficult to apply a liquid-type coating with a brush, it is recommended to apply a spray-type coating. When repairing by spray, it is advisable to fasten the bolt of the ground clamp and spray from upwind to prevent the person who is spraying from inhaling the spray. Measures must also be taken to prevent the spray from dispersing into private houses or dripping onto the ground. 3.2.3 Scratches during attachment of universal bandWhen attaching a universal band (Fig. 5(D)), an operator uses a hammer to fit the band to the pole, but it is recommended to use a resin hammer instead of a normal (metal) hammer because a metal hammer may damage the coated surface of the band. As shown in Fig. 6, even a resin hammer can peel of the coating due to the impact of striking, so any peeled areas should be repaired by re-applying the coating by brush.

3.2.4 Fastening points of wire gripper, branching fixture, and end clampAt the fastening points of a wire gripper (Fig. 5(E)), branching fixture (Fig. 5(F)), and end clamp (Fig. 5(G)), the tightening force will cause scratches and dents on the coated surface of the messenger wire. To repair that damage, it is recommended to apply a liquid-type coating to the area where the wire gripper was installed and apply a spray-type coating to other areas (i.e., confined spaces) in the same manner as for the ground clamp. 4. ConclusionTo protect telecommunication equipment and facilities from corrosion caused by environmental effects such as salt damage, it is effective to apply a strong corrosion-prevention powder coating; however, it is necessary to consider certain points of note in the design and installation of powder-coated equipment that do not apply to normal processes. By paying attention to these points and carrying out appropriate installation and repair, the excellent anti-corrosion performance of a coated surface will be manifested, and the lifespan of the coated equipment will be extended to the full. TASC will continue to engage in technical cooperation to solve problems in the field, such as issues related to equipment and facility deterioration due to salt damage and other types of corrosion, and contribute to improving the quality and reliability of telecommunication services. References

|

|||||||||||||||||