|

|||

|

|

|||

|

Feature Articles: Urban DTC for Creating Optimized Smart Cities Attentive to the Individual Vol. 22, No. 5, pp. 78–84, May 2024. https://doi.org/10.53829/ntr202405fa10 Robot Delivery Service with Mobile OrderingAbstractIn urban office districts, there is a movement toward using indoor mobility solutions, such as using robots, to provide necessary services, such as cleaning, security, and delivery, for tenants and building owners to reduce operational costs. Anticipating the use of multiple robots for various services within buildings, efforts are underway to implement systems involving multiple heterogeneous robots. This article discusses efforts toward achieving robot delivery services via mobile ordering, enabling busy office workers to make retail purchases while in the office. It focuses on the development of optimal robot-control technology that accurately predicts robot delivery times and explores optimal travel routes to ensure timely delivery. Keywords: AI, robot, digital twin 1. What are robot delivery services?A robot delivery service is a service in which users can freely select the destination, delivery point, and time for their ordered items, which are then delivered by robots. Users place orders and make payments to the store using a dedicated mobile ordering service on their smartphones or similar devices. The order information is transmitted to the robots, which then collect the items from the store and deliver them to the specified locations according to the order information. After completing the delivery, the robots return to a designated location, where they wait for the next order while charging the battery as needed. As shown in Fig. 1, if there are multiple orders at the same time, they will be consolidated and delivered in a single robot delivery. If a new order comes in after the robot has departed, another waiting robot will be used for the delivery.

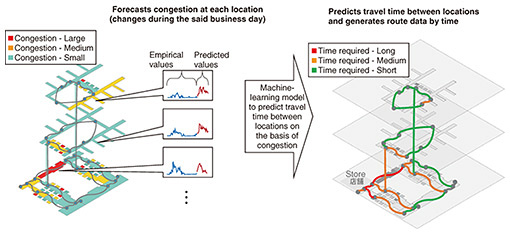

Introducing robot delivery services to office buildings provides a new value experience by delivering goods to busy office workers at their desired locations and times when they do not have time to go shopping. This contributes to creating new sales opportunities for understaffed stores by providing delivery services without the need for additional personnel. To provide robot delivery services, it is necessary to eliminate the task of manually calculating and setting the robot’s travel routes while considering the order details. Therefore, we have developed optimal robot-control technology, enabling automatic and efficient route calculation without human intervention. 2. Challenges with robot delivery servicesTo implement a robot delivery service, there are requirements to minimize the number of robots and travel time for successive orders and predict and provide the delivery time in advance so that users can efficiently receive the products. Three main factors affect travel time. 1) Robots attempt to avoid collisions by detecting obstacles during travel and slowing down or temporarily stopping if an approach is detected. This avoidance action increases the robot’s travel time, so it is necessary to consider congestion on the route and the use of building facilities (such as elevators). 2) It is necessary to consider the operating hours of the store. Store staff gather the targeted items while checking the order details, and when the robot arrives at the store, they load the items onto it. Additional tasks, such as warming up certain items, may also occur. The time required for this series of tasks is not always constant and varies greatly depending on the characteristics of the ordered items and congestion of the store, so consideration is necessary. 3) It is necessary to consider competition between robots. For example, if two robots are running side by side, they may perceive each other as moving obstacles and repeatedly decelerate or pause to avoid collision. When two robots pass each other in a corridor, there is a risk of them getting stuck as they fail to avoid each other properly, potentially resulting in the halt of delivery. The simultaneous movement or passing of robots could disrupt pedestrians, making it crucial to avoid such situations altogether. 3. Optimal robot-control technologyOur optimal robot-control technology is a solution to the above-mentioned challenges. It involves graphing the routes of spaces targeted for robot delivery services, such as city blocks and buildings, and searches for the optimal route by predicting the travel time for each route and point as well as the competition between multiple robots. This technology encompasses four other technologies: 1) route-time prediction, 2) store-loading-time prediction, 3) optimal-route search on the graph, and 4) priority control for resolving robot competition. In this context, nodes in the graph represent waiting points for robots, loading points for stores, reception points for users, and branching points for routes (including waiting points for elevators), while edges represent passages between nodes. 3.1 Route-time-prediction technologyFigure 2 gives an overview of the route-time-prediction technology. It involves collecting data on pedestrian flow and elevator-operation status to quantify the congestion levels at each point. Using machine learning, future congestion levels are predicted on the basis of past performance data. By predicting the travel time for each route on the basis of the forecasted congestion levels, the travel time for each route (edge) at the time of delivery initiation can be obtained. The obtained travel times are used as costs for the corresponding edges in the graph structure.

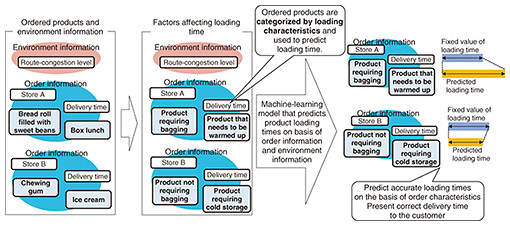

The travel time for each route varies significantly depending on the congestion levels along the route. This is due to the presence of many people on the route (moving randomly and requiring the robot to avoid collisions), resulting in repeated abrupt stops by the robot and requiring more irregular travel time compared with uninterrupted travel. This phenomenon applies similarly to optimal route exploration on the graph, where route selection based on congestion levels is essential to achieve optimal routes and accurate estimates of travel time. This technology enables accurate planning of operations by estimating delivery times considering environmental and time changes, minimizing the deviation between actual and estimated values and enabling the use of accurate travel times for operational planning. 3.2 Store-loading-time-prediction technologyFigure 3 gives an overview of the store-loading-time-prediction technology. The time required for the series of tasks from preparing the items to loading them onto the robot varies significantly depending on the characteristics of the ordered items and congestion levels in the store. Therefore, the ordered items are classified on the basis of characteristics that affect loading, such as whether they belong to categories that require warming or need to be fixed in a drink holder, using basic information about the ordered items (name, description, etc.). On the basis of these characteristics and the congestion levels in the store, the loading time is then predicted. The predicted loading time is used as costs for nodes corresponding to each store in the graph structure.

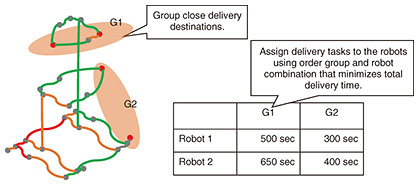

This technology enables the calculation of loading times on the basis of the characteristics of the ordered items, thereby minimizing the deviation between actual and estimated values. 3.3 Technology for optimal route search on the graphThe technology for optimal route search on the graph calculates the route with the minimum travel time using the graph with the cost calculated with the above two technologies. A graph is predicted and created at the time of delivery on the basis of order information, and the shortest route between each point (waiting points, loading points, reception points, waiting points) to be passed during delivery is calculated from the graph. If there are multiple orders simultaneously, orders with nearby destinations are grouped sequentially, and the shortest routes and travel times are calculated for each robot assignment, optimizing the allocation to minimize the total time. Figure 4 outlines this process.

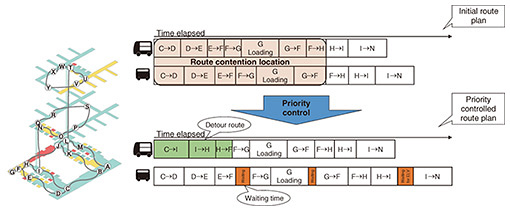

This technology takes into account environmental and time changes, selects the optimal route among multiple routes, and devises an efficient operational plan. 3.4 Priority-control technology for resolving robot competitionFigure 5 gives an overview of the priority-control technology for resolving robot competition. To operate multiple robots within the same area, it is necessary to avoid overlap and competition of the planned travel routes of each robot. For example, in the figure, there are multiple overlapping points as two robots move from points C to N. To avoid route conflicts, diversion routes or waiting times are set to ensure that each robot does not pass through the same route at the same time. This resolves route competition by avoiding collisions and being stuck between robots with the minimum additional time. The same procedure is followed to resolve competition when there are three or more robots.

With this technology, it is possible to mitigate the delay factors in operational planning, such as route overlap and competition, and the resulting travel time delays, which cannot be suppressed by optimal route search on the graph, when multiple robots are operated simultaneously. 4. Evaluation of optimal robot-control technologyWe evaluated robot delivery services using our optimal robot-control technology through a demonstration experiment targeting an office building [1]. Among the four elements comprising our optimal robot-control technology, we evaluated the route-time-prediction technology and the technology for optimal route search on the graph. We developed a system for the experiment in which workers in the building can order items from the building’s restaurants using a dedicated mobile ordering service. The robots were capable of traversing floors by collaborating with elevators and autonomously travel from the loading point in front of the restaurant to the reception point on the floor where the user worked. If the robot arrived at the reception point and nobody receives the items within 10 minutes, it was determined that the user was unavailable to receive them, and the robot returned to the restaurant. The items returned to the restaurant were held there, and the user would then need to retrieve them directly from the restaurant. We provided two patterns for order placement: scheduled delivery and immediate delivery. Scheduled delivery allows users to select a desired time slot from 30-minute intervals throughout the day and place their orders accordingly. Immediate delivery automatically selects the earliest available time slot for delivery and places the order. After receiving orders in both of the above formats, the robot delivery service uses our optimal robot-control technology to execute optimal route searches. The robots are then scheduled to follow these routes accordingly. The estimated delivery time is also calculated on the basis of the predicted travel time and presented to the user in advance. We used thermopile-type sensors to acquire congestion information. These sensors contain non-contact temperature sensors capable of detecting and measuring human body-heat radiation. Installed on the ceiling, the thermopile-type sensors measure the number of people within their detection range directly below them, which we used as a measure of congestion at that location. The demonstration was conducted from October 2022 to March 2023. The period was divided into two halves: the first half focused mainly on collecting basic data, confirming operational flows of the restaurants, and conducting interviews with users. During the second half, evaluations were conducted while actual users placed orders. During the evaluation, we compared the predicted arrival time presented to the users with the actual arrival time. Three comparison patterns were prepared as follows.

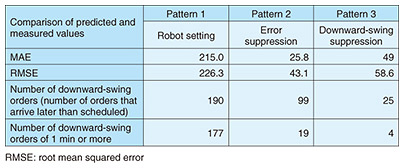

We constructed a downward-swing-suppression model of Pattern 3 in response to the user’s viewpoint that there is no problem if the robot arrives before the scheduled time because the user plans to pick up the product at the indicated arrival time. Pattern 3 is the model in which the robot is more likely to have arrived by the expected arrival time for the user to be able to receive the product, although the error is larger than in the error-suppression model of Pattern 2. The results are listed in Table 1.

Comparing Patterns 1 and 2, the error (mean absolute error (MAE)) was reduced from 215 to 25.8 seconds. The number of downward-swing orders that arrived later than scheduled, causing users to wait, decreased from 190 to 99, demonstrating a substantial improvement by using our optimal robot-control technology. A comparison of Patterns 2 and 3 revealed that the number of downward-swing orders can be reduced to about one-fourth by using the downward-swing-suppression model, although the error is larger. It is important to choose between the error-suppression and downward-swing-suppression models depending on the situation. However, from the user’s viewpoint, the downward-swing-suppression model is often considered more effective with less waiting time, and from the operator’s viewpoint, the error-suppression model can plan robot operations more efficiently. 5. Future outlookBy using our optimal robot-control technology, it is possible to accurately predict travel times and conduct optimal route searches. Moving forward, we will conduct evaluations and improvements through demonstration experiments for the store-loading-time-prediction technology and the priority-control technology for resolving robot competition. This will further optimize our optimal robot-control technology. By controlling not only delivery robots but also various other robots, such as those for cleaning and security, on an integrated platform, optimization and labor saving can be achieved for an entire city block. Reference

|

|||