|

|

|

|

|

|

Regular Articles Vol. 22, No. 9, pp. 86–92, Sept. 2024. https://doi.org/10.53829/ntr202409ra3 Work-improvement-support Technology That Supports Wide-ranging Implementation and Application of Digital Transformation MeasuresAbstractTo make operations of an organization digital, i.e., digital transformation (DX), companies and local governments are promoting on-site efforts to improve business efficiency using digital technology and the implementation of measures by DX-promotion departments. To further enhance the effectiveness of DX promotion, it is necessary to create a DX cycle in which workers in the field and DX-promotion departments cooperate to efficiently and accurately implement effective DX measures over a wide area. The work-improvement-support technology developed by NTT to meet this necessity is introduced in this article. Keywords: DX promotion, business analysis, operations 1. Importance of implementing DX measures in collaboration with workers in the field and DX-promotion departmentsThe use of digital technology is an effective means to achieve business transformation that can promote both operational efficiency and new-value creation in response to rapidly changing social and economic conditions. Companies and local governments are promoting organization-wide digital transformation (DX) of operations, such as field-led improvement of work efficiency through digital technology (field-led DX) and implementation of digital technology by DX-promotion departments. Field-led DX has made progress in terms of automating and streamlining work procedures through the use of tools that automate desk work such as robotic process automation (RPA). However, field-led DX is often designed and implemented in a manner that is optimized for individual field operations; therefore, it is difficult for workers in other fields to determine whether the conditions for using field-led DX are compatible with their work. Currently, the only way to compare DX measures and field work is to observe and compare each manually, which requires many operations simply to select applicable examples from a variety of DX measures implemented at other fields. It will be important to improve business practices and procedures flexibly with a sense of urgency to meet the needs of society. This issue is faced by DX-promotion departments, and smooth rollout of DX measures is an essential element of fundamental business improvements that will have an impact throughout the company. Accordingly, to further increase the effectiveness of DX promotion, it is necessary to create a DX cycle in which workers in the field and the DX-promotion departments cooperate in a manner that efficiently and accurately implements effective DX measures in a wide range of areas (Fig. 1).

2. Overview of work-improvement-support technologyTo address the above issues, NTT Network Innovation Center developed work-improvement-support technology, which is based on technology developed at NTT Access Network Service Systems Laboratories, that can be used immediately in the field and in DX-promotion departments. This technology uses historical information on operations carried out on personal computers (PCs) (operation logs) to quantitatively compare and visualize DX measures and the work procedures at the site that is considering applying the measures. The technology provides the following two tools that can be used immediately in the field or in DX-promotion departments.

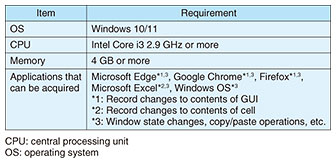

Using these tools makes it possible to quantitatively compare DX measures and on-site work to which those measures are considered being applied by using operation-log data accumulated in real time from daily work. These tools thus make it easier to objectively determine the suitability of DX measures on the basis of the actual state of work operations. 3. Operation-log-acquisition toolThe operation-log-acquisition tool records operation history of the screen and GUI on PCs in real time as an operation log. The tool is installed in a PC in the Windows environment and records operation logs in file format according to operations by workers and automation tools such as RPA (see Table 1 for operating environment). The tool detects user input operations and changes in application and window statuses on the terminal screen and captures the operations carried out by the user as operation events. This information can also be recorded and saved as log files (in text format) at an arbitrary location. The operation screen can be recorded and saved as a captured image upon detection of an operation event.

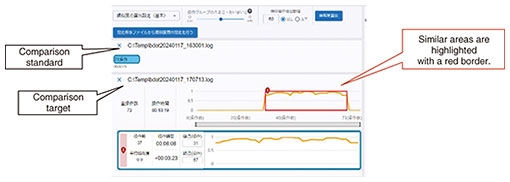

4. Operation-log-analysis toolThe operation-log-analysis tool compares the similarity of work procedures from the data of the obtained operation logs and visualizes them in an easy-to-understand format. It has the following three functions. (1) Automatic extraction and visualization of similarities from work procedures The similarity between work procedures is quantitatively evaluated from the two types of operation-log data, and the evaluation results are used to visualize similar and dissimilar points of procedures (see “Similarity assessment based on operation co-occurrence” below for details of the evaluation technique). The screenshot in Fig. 2 is an example of analyzing and visualizing the similarities between the two types of operation-log data. For example, when the operation-log data concerning a DX measure are used as the comparison standard, and the operation-log data concerning the work at the site where the application of the DX measure is being considered are used as the comparison target, an operation range similar to that of the DX measure is extracted. This range is highlighted with a red border, so it is possible to see at a glance the similar points of work procedures. Similarly, dissimilar points can also be extracted by specifying the settings.

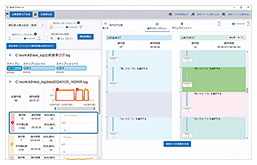

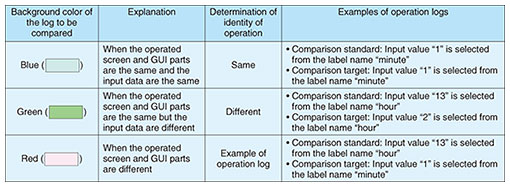

(2) Detailed comparison of similar work procedures The similar operation ranges of each operation extracted by function (1) are arranged side-by-side, and the similarities between them are compared in detail. The screen shot in Fig. 3 is an example of visualizing similar operations side-by-side. For example, if the background color of the operation logs to be compared is blue or green, the user can see at a glance that the operations are similar; if it is red, the operations are different (see Table 2). Each operation is converted into an explanation expressed in natural language that can be read and understood directly by the user (see “Generation of explanatory information about operation” below for details). This function makes it possible to understand the operations that can implement DX measures at the operational level.

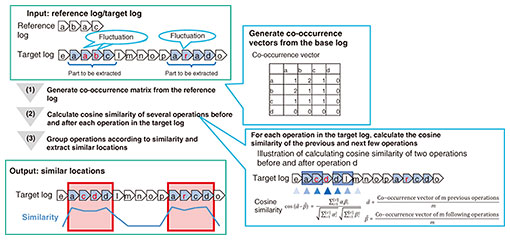

(3) Generation of material for manuals from operation logs By combining the text data of the operation history acquired as an operation log with screen-capture data, it is possible to generate a document file combining the work procedure and screen of the corresponding work target as material for the manual. This function makes it possible to identify specific work procedures related to DX measures and on-site work and can be used as an aid for creating manuals used in implementing DX measures. 5. Features of NTT technology5.1 Similarity assessment based on operational co-occurrenceOperation logs often contain fluctuations due to, for example, rework or interruptions by other operations, which depend on the situation during the operation. Therefore, NTT Access Network Service Systems Laboratories developed a technology for evaluating the similarity of operations by using operational co-occurrence, which means that operations involved in similar work show mutual co-occurrence. This technology absorbs fluctuations in operations, correctly evaluates the similarity of operations, and exactly matches the range of similarity if they are similar, even if the operations are not exactly the same. The similarity-assessment technology based on operational co-occurrence sets one operation log as a reference log and extracts parts that are similar to the reference log from another operation log containing the operation target (target log). This technology involves the following three steps (Fig. 4). (1) Information on operation events located closely together and near the reference log is stored as a co-occurrence matrix. (2) The cosine similarity of the previous and next few operations from a given operation in the target log is calculated using the information on the co-occurrence vector of the reference log created in step (1). This similarity is calculated for all operations in the target log. The key point of this technology is that it uses the co-occurrence vector and similarity between several operations before and after the target operation in the target log. By appropriately rounding off the sequential order in the operation log, it is possible to calculate a similarity close to the semantic similarity recognized by people. (3) The operations are grouped in accordance with their similarity and extracted as matching and mismatching regions.

5.2 Generation of explanatory information about operationsThe operation log records information that indicates operation history, such as the time the operation was carried out and GUI-component information, but it is in machine language, which is unsuitable for viewing and understanding by people. Therefore, NTT Access Network Service Systems Laboratories developed a technology that can be used as explanatory information by mapping labels to GUI components. The technology takes advantage of the fact that labels that are easy for people to understand are expressed next to the GUI components. This makes it possible to generate text explaining operation procedures automatically from operation logs in a manner that makes it possible to visualize the operation without much effort. Logs can be obtained not only for operations carried out by people but also for operations executed with automation tools such as RPA, and explanatory information can be generated to facilitate understanding of the execution content of automated operation scenarios. This technology involves the following three steps (Fig. 5). (1) On the basis of the format recorded in the acquired operation log, rules are used to determine the appropriate sentence structures for the explanatory text and the parts of speech that make up the text. (2) Two elements, parent-child relationships in the HTML and positional relationships on the display screen, are focused on, and the correspondence with nouns (labels) that describe the GUI components at the operation location is inferred from information around the GUI components on the screen. (3) Explanatory text based on the sentence pattern determined in step (1) and the label obtained in step (2) is generated.

6. Use casesThree example situations in which the two above tools can be used are given below. (1) Creation of DX cycle through collaboration between the workers in the field and DX-promotion departments DX-promotion departments can use these tools to quantitatively compare the work involved in field-led DX measures and work involved in the field that is considering implementing the measures, and they can analyze and determine whether the measures are compatible. The tools thus enable efficient and accurate implementation of DX measures in line with on-site operations. (2) Expanding the scope of automation by evaluating the applicability of RPA scenarios By comparing work automated by tools such as RPA as DX measures with manual work, it is possible to identify the scope of the RPA scenario. It thus becomes possible to identify similar areas as candidates for RPA implementation and consider further improvements in business efficiency for the areas that differ. (3) Assistance in improving work skills through comparison with more-efficient employees By using these tools to compare differences in work procedures executed by employees with high work efficiency, we can identify effective work carried out by certain employees that is not being carried out by other employees and use it as a teaching tool to improve the skills of the latter employees. Using this teaching tool will help create new DX measures that will improve overall operational efficiency. 7. Future developmentsWork-improvement-support technology for creating a DX cycle in which workers in the field and the DX-promotion departments cooperate to efficiently and accurately implement effective DX measures was introduced. This technology has just completed product development and can now be used for various DX-promotion measures. We plan to promote application of this technology to actual business operations and commercialization in the general market. |