|

|

|

|

|

|

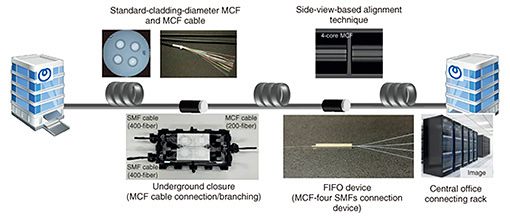

Front-line Researchers Vol. 23, No. 4, pp. 7–12, Apr. 2025. https://doi.org/10.53829/ntr202504fr1  Accelerating Practical Application of 4-core Optical Fiber with the Same Cladding Diameter as Current Optical Fiber and Advancing Power-over-fiber TechnologyAbstractIt is becoming increasingly necessary to expand network communication capacity to accommodate the increase in data transmission between datacenters due to the evolution of generative artificial intelligence and the increase in data transmission due to the spread of extended-reality services. To expand network-communication capacity, it is necessary to not only improve the capacity of the transmission system but also the transmission medium, namely, optical fiber. A multi-core optical fiber (MCF), in which multiple cores (i.e., the paths through which light travels along the optical fiber) are arranged spatially in a single optical fiber, has been developed, and a 12-core MCF—the world’s highest core density—is appearing. Technologies for applying optical fiber to non-communication areas, such as measuring loss by using the scattering of light passing through optical fiber, have also been developed. Kazuhide Nakajima, a senior distinguished researcher at NTT Access Network Service Systems Laboratories, is working to put 4-core MCF into practical use as soon as possible and apply MCF to non-communication areas. We talked with him about the essential technologies for deploying 4-core MCF in the field, power-over-fiber (PoF), i.e., optical-power-supply technology, using MCF, international standardization of MCF, and the importance of connection points in research and the mindset required to find and use them. Keywords: optical fiber, multi-core optical fiber, power-over-fiber system Establish technologies for deploying 4-core optical fiber with a 125-μm cladding diameter in the field—Could you tell us about the research you are currently conducting? My basic research areas are sustainable large-capacity optical transmission lines, creation of new value by adding functions to optical fibers, and promotion of international standardization, and I am currently focusing on practical deployment of multi-core optical fiber (MCF) and application of MCF to non-communication areas. To increase the transmission capacity of optical fiber, I am currently researching space-division-multiplexing optical fiber, namely, MCF, which has multiple cores acting as light paths within a single optical fiber. In my previous interview (April 2022 issue), I talked about how we designed and prototyped an optical fiber with more than 100 times the potential of current optical fiber in terms of both the amount of spatial multiplexing and spatial-utilization efficiency by incorporating 12 cores—each capable of 10-mode propagation—in a single optical fiber. The cladding diameter of this 12-core 10-mode MCF is 220 μm, whereas that of current optical fiber is 125 μm. If the cladding diameter of MCF is the same as that of current optical fiber, many current technologies for manufacturing, installation, and connection of optical fiber cables can be used; thus, it will be possible to promptly put MCF into practical use. Therefore, we have been conducting research on 4-core single-mode MCF with a cladding diameter of 125 μm and have now virtually reached the point of practical use in terms of fabrication technology. When deploying optical fiber in the field, the connections between optical fibers and between optical fiber and transceivers/receivers are critical. When two optical fibers are connected, misalignment of cores in the cross-sections at the connection points can cause leakage of light and increase transmission loss of the optical signal; it is therefore essential to connect the cores (with diameter less than one-tenth that of the optical fiber) while minimizing their misalignment. That requirement also applies to connections between optical fiber and transceivers/receivers. In the case of 4-core MCF, all four spatially arranged cores must be aligned. To construct (and practically use) optical transmission lines using 4-core MCF, it is necessary to establish four underlying technologies, i.e., side-view-based alignment, MCF cable connection and branching (underground closure), fan-in/fan-out (FIFO) devices, and central office MCF accommodation and wiring (central office connecting rack), at a level that is usable on-site (Fig. 1).

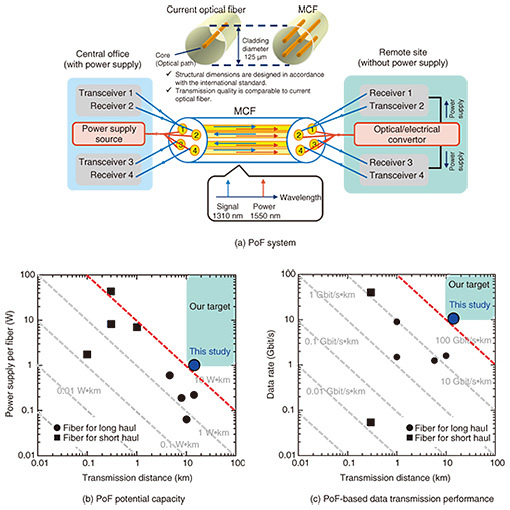

Regarding a side-view-based alignment technique, the positions of the four cores of 4-core MCF are identified by observing and analyzing side-view images of two opposing 4-core MCFs and automatically rotated and aligned in a manner that minimizes misalignment of all the cores in those MCFs. The concept of automatic adjustment of the coordinates in the direction of the rotational axis of the fiber was conceived about eight years ago, and it was confirmed that the concept could be put to practical use if the positional deviation of the rotation angle could be adjusted to within 0.5 degrees. It was conventional to directly observe the end face of the optical fiber and align the direction of the rotation axis accordingly; however, this procedure required an optical system for observing the end face of the optical fiber, and that system was difficult to incorporate into a small, portable fusion splicer. We therefore developed a side-view-based alignment technique for 4-core MCF. For connection between 4-core MCFs, a number is assigned to each core in the cross section on the basis of a reference point called a marker. The luminance distribution of the cores at the connection point in the side-view image is then analyzed, and the rotation angles of the opposing fibers at which the luminance distributions in both connected fibers match is derived, and the rotation alignment is executed. By incorporating this side-view-based alignment technique into a general-purpose optical-fiber fusion splicer, a permanent connection between MCFs is possible not only in laboratory environments and factories but also on-site. An underground closure is used to connect and branch small-diameter, high-density optical cables incorporating MCFs or currently used optical fiber (i.e., single-mode optical fiber (SMF)) cables in underground facilities. Since 4-core MCFs have the same cladding diameter as SMFs, the basic structure of existing underground closures can be reused efficiently when MCF cables are deployed. An FIFO device is used to combine and branch a 4-core MCF with four single-core SMFs. Developed in collaboration with NTT Innovative Devices, this device has a two-layer structure in which silica-based planar-lightwave-circuit (PLC) waveguides are stacked in the vertical direction, and two cores are interconnected and branched on the first and second layers, respectively. Characterized by their high reliability and ease of mass production, silica-based PLC waveguides are widely used for optical-power branching in optical transmission systems. The central office MCF accommodation and wiring technology terminates MCF cables at central office equipment and interconnects it with SMFs via FIFO devices installed in the connecting rack in the central office. By directly connecting the 4-core MCF to a connector using FIFO devices, the cross-sectional area required for the connection can be reduced to less than one-quarter the space required for current optical fibers. We established these four underlying technologies for the construction, maintenance, and operation of 4-core optical transmission lines in 2024 at a level that enables them to be used on-site, and we plan to deploy them in the field from 2027 to 2028. PoF system as a new application of MCF to non-communication areas—What kind of technology are you investigating in application of MCF to non-communication areas? I am investigating a power-over-fiber (PoF) technology that transmits two types of optical signals, one for communications and one for power supply, over a single MCF. This technology can also be used in combination with transmission equipment for normal optical communications (optical communications that do not require an optical power supply). Since each core can be used independently (without interference between optical signals of each core), any core can be assigned to either power supply or communications, or both. Although the basic concept of this technology has existed for some time, in the case of the conventional technology, when the input light exceeds a certain threshold of optical intensity, it is converted to light of a different wavelength, and the optical intensity on the output side becomes saturated. Therefore, it is impossible to supply more than 1 W of electrical power to a location more than 10 km away. In our experiment, to maximize the amount of optical power supply, a 1550-nm light source was input to the four cores. The communication wavelength was set to 1310 nm, and two cores were assigned to uplink and downlink signals, respectively, to enable bidirectional optical communications. Therefore, two sets of bidirectional transmission systems can be configured with 4-core MCF (Fig. 2(a)). The capacity of optical power supply can be expressed as the product of transmission distance and supplied power. By leveraging MCF to maximize power supply per unit cross-sectional area and suppress return light in the transmission systems, which can degrade the efficiency of optical power supply, we demonstrated a world-record PoF potential capacity of 14 W·km (approximately 1 W of power is supplied over a transmission distance of 14 km) (Fig. 2(b)). We also demonstrated self-powered bidirectional optical communications with a data rate of 10 Gbit/s, which is currently the highest available in optical communication services for general users. We confirmed excellent transmission characteristics after 14-km transmission using a two-core system with uplink and downlink transmissions. Considering the product of data rate and transmission distance as an index of transmission performance concerning self-powered optical transmission, we achieved the world’s highest transmission performance of 140 Gbit/s·km (Fig. 2(c)).

This technology can improve network resilience in the event of a disaster or emergency, i.e., communication equipment can be driven by sending optical power from a central office to areas where it is difficult to restore power. It will also make it possible to provide optical communication services in any location, such as non-electrified areas near rivers and mountainous areas, as well as areas where electrification is challenging due to strong electromagnetic fields or corrosion. It is thus expected to contribute to the implementation of sensing networks that link with various Internet-of-Things devices. —Are you continuing to be involved in international standardization? Yes. I continue to serve as a rapporteur for Question 5 of Study Group (SG) 15 (Transport, access & home) at the International Telecommunication Union - Telecommunication Standardization Sector (ITU-T). At Question 5, which concerns “Characteristics and test methods of optical fibres and cables, and installation guidance,” MCF was considered necessary in the future and has been under discussion since around 2015. Discussions aiming to make a 125-μm-cladding-diameter, 4-core MCF the subject of international standardization have been underway from around 2020, and a resolution to formulate a recommendation (international standard document) will be discussed at the SG15 meeting in March 2025 (at the time of this interview). I expect that drafting the resolution will take about a year, after which it will ultimately be developed as a G-series recommendation. Toward this standardization, members of the International Electrotechnical Commission working on international standardization of optical fibers, optical cables, connectors, and other equipment are sharing information with ITU-T SG15 participants and united in their awareness to achieve the effective international standardization of MCF technology. Finding connection points between technologies and between people and broadening the scope of research through new ideas—What do you keep in mind as a researcher? When researching a certain topic, although researchers tend to focus on achieving world records and research results, I try to find the connection points with areas peripheral to the topic. When research into FTTH (fiber-to-the-home) was at its peak, my research group was working on a free-bending optical cord. Conventional optical fibers are made of silica glass, so bending them increases transmission loss of the light that they are transmitting and can even break them. At that time, we were researching a new type of optical fiber made of silica glass with multiple air holes. Our group leader had the idea of applying this hole-assisted optical fiber technology to the free-bending optical cord, and we began researching that idea and were able to put it into practical use. That research is just one example of finding a connection point between technologies; however, connection points also exist between people. Therefore, in our current research, we are always conscious of finding connection points between technologies and people. In standardization meetings, important matters are often resolved through lobbying and conversations during breaks, and the results of these informal conversations are then agreed upon at the meeting. Connection points between people are thus meaningful and key to make your presence felt in these types of meetings. Similarly, at academic conferences, it is often the case that going over to the presenter after a presentation and asking questions and discussing the matter deepens your insight and advances the research of both parties. In this case, taking action yourself creates connection points. Although research on MCF began around 1980, the concept was ahead of its time because we lacked the technology for connecting multiple cores between fibers. When I joined the company, I was inspired by the imagination and efforts of my predecessors and became interested in MCF and started researching it. Now, more than 30 years later, MCF is becoming a reality, which makes me feel quite emotional. However, in the world of optical fiber and cables, interconnectivity with current facilities and backward compatibility are extremely important factors that we must always consider when introducing them into the field. Just because it is a new technology does not necessarily mean it will be successful. I believe that MCF is becoming a reality largely due to the fact that the field side has been voicing out ideas about how to upgrade optical-fiber facilities, and the research side has continued to take into account those ideas. I will keep this fact in mind as we approach the final stage of introducing 4-core MCF into the field. In standardization activities, I intend to fill in the gap between concept and practice while keeping in mind connection points with other technologies and drawing on these experiences. Connecting your values to your research topic—What is your message to young researchers? I have recently come to think that it is extremely important for each researcher to connect the values they possess to their research topic. Researchers have a precise understanding of the technical challenges they face and know how to proceed with their research; however, I believe that by applying their own values when considering research topics and how to proceed, they can add depth and significance to their research. I want young researchers to not only approach research as a single technical issue and proceed from a purely technical perspective but also think about what new things can be created by adding their own values to their research. I think this approach will enable them to do some very interesting things, and I want them to challenge themselves to turn that possibility into reality. ■Interviewee profileKazuhide Nakajima received an M.S. and Ph.D. in electrical engineering from Nihon University, Chiba, in 1994 and 2005. In 1994, he joined NTT Access Network Service Systems Laboratories, where he has been engaged in research on optical-fiber design and related measurement techniques. He has been acting as a rapporteur of Question 5 of ITU-T SG15 since 2009. He is a member of the Institute of Electrical and Electronics Engineers (IEEE), Optica, the Institute of Electronics, Information and Communication Engineers (IEICE) of Japan and the Japan Society of Applied Physics (JSAP). |