|

|||||||||

|

|

|||||||||

|

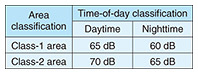

Practical Field Information about Telecommunication Technologies Vol. 23, No. 8, pp. 23–26, Aug. 2025. https://doi.org/10.53829/ntr202508pf1 Investigations on Traffic Vibration around Telecommunication Facilities: Maintenance Holes as an ExampleAbstractTechnical Assistance and Support Center, NTT EAST is investigating vibrations due to traffic around NTT EAST’s telecommunication facilities to evaluate their impact on the surrounding area. This article presents results of investigations of traffic vibrations around a maintenance hole. Keywords: traffic vibration, maintenance hole, resonance frequency 1. IntroductionNTT EAST’s facilities are spread throughout Japan in various forms so that they can deliver telecommunication services to all parts of the country. For example, utility poles and maintenance holes are installed in residential areas, so it is necessary to harmonize with the local community and ensure that they do not disturb the living environment of residents. As part of efforts to ensure that telecommunication facilities do not disrupt the lives of local residents, the Materials Engineering Group at Technical Assistance and Support Center (TASC), NTT EAST is investigating vibrations due to traffic around NTT EAST’s facilities to evaluate their impact on the surrounding area. This article introduces the results of investigations targeting a maintenance hole. 2. Overview of investigationsWhen heavy vehicles, such as trucks, are travelling along roads, their vibrations are transmitted into the ground, and that transmission causes the road to vibrate. The magnitude of the vibration depends on the condition of the road surface and strength of the ground. If large vibrations propagate through the ground and reach houses adjacent to the road, people inside those houses may feel the vibrations. NTT’s maintenance holes are buried underground along roads, so they may affect those vibrations by resonance. TASC therefore conducted the following two investigations around a target maintenance hole. 1. Investigate the vibration state around the maintenance hole by measuring vibration levels. 2. Investigate the presence or absence of resonance with the maintenance hole by measuring the frequency of traffic vibration. 2.1 Investigation 1: Vibration levels(1) Overview of investigation The spaces in which people live are subject to numerous vibrations such as those caused by factory machinery, by civil engineering and construction work, and by trains and large vehicles. To protect the living environment of local residents, the Vibration Regulation Act [1] was enacted in 1976 to set limits on the vibration level (i.e., an index, measured in decibels, expressing the magnitude of vibration). Since then, the government has taken vibration-prevention measures such as providing guidelines to businesses and repairing road surfaces. The required limits on vibration levels are set by the enforcement regulations of the Vibration Regulation Act as listed (as standard values) in Table 1. The vibration level for each class of vibration is measured and evaluated on the basis of whether it exceeds the standard values stipulated in Table 1. In investigation 1, the vibration level around a target maintenance hole installed in a road passing through a residential area was measured.

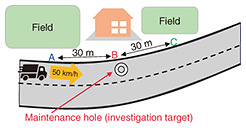

(2) Method of investigation Vibration levels were measured using the measurement equipment specified in JIS (Japanese Industrial Standards) C 1510. As shown in Fig. 1, the measurement points were near the target maintenance hole in a road (point B) and at two nearby (30 m from B) locations where maintenance holes are not buried in the road (points A and C). To ensure measurement reproducibility, a bucket truck (weight approximately 6 t) was driven past points A, B, and C multiple times (at speed of 50 km/h), and the vibrations generated by the moving truck were measured at each point. The vibration direction measured was taken as vertical in accordance with JIS Z 8735.

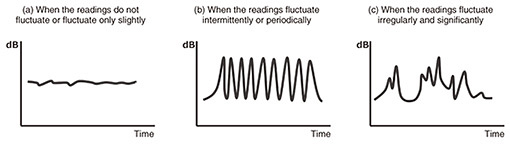

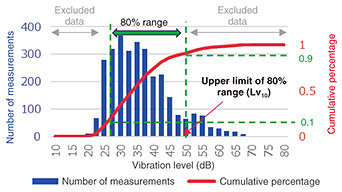

The three general patterns of the measured vibration waveforms are shown in Fig. 2. According to the guidelines of the Ministry of the Environment [2], it is recommended that the method of measuring the vibration level be changed according to the vibration pattern being measured. For example, when the vibration-level meter readings do not fluctuate or fluctuate slightly (Fig. 2(a)), each reading can be used as the measured level as is; in contrast, when the readings fluctuate intermittently or periodically (Fig. 2(b)), the average of the maximum measured values for each fluctuation is taken as the measured level. Traffic vibration, which occurs only when vehicles are passing, corresponds to the pattern shown in Fig. 2(c); namely, the vibration-level meter reading fluctuates irregularly and significantly. In this case, the upper limit of the 80% range is taken as the measured vibration level and its magnitude is evaluated.

The 80% range refers to the remaining 80% of multiple measured vibration levels arranged in order of magnitude, after the maximum 10% and minimum 10% have been excluded, as shown in Fig. 3. The maximum vibration level within the 80% range is taken as the upper limit of the 80% range (Lv10).

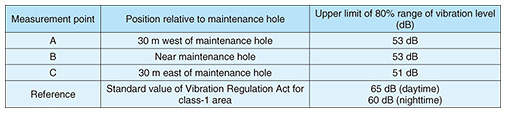

(3) Results of investigation The measured vibration levels (Lv10) are listed in Table 2. According to these investigation results, none of the vibration levels measured at the three measurement points exceeded the standard values stipulated in the Vibration Regulation Act. Also, Lv10 values measured near the maintenance hole (point B) and at the other two points (A and C) did not significantly differ, indicating no particularly large (or small) vibrations occurred near the maintenance hole. It can be concluded from these results that when the vehicle passed the target maintenance hole, no vibrations that exceeded the legal standard values were generated, and regardless of whether a maintenance hole was buried nearby, no significant differences in the vibration levels at each measurement point were observed.

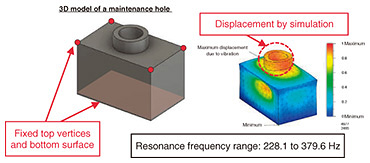

2.2 Investigation 2: Vibration frequency(1) Overview of investigation We investigated vibration frequency to ascertain any effect of the maintenance hole on traffic vibration. It is thought that the effect of a maintenance hole (buried underground) on traffic vibration is one of resonance between the traffic vibrations and the maintenance hole that amplifies the vibrations. We therefore verified whether the maintenance hole resonated by comparing the frequency of vibrations observed on site with the resonance frequency of the maintenance-hole casing. (2) Method of investigation First, we created a three-dimensional (3D) model (see Fig. 4) from a drawing of a maintenance-hole casing and calculated the resonance frequency by displacing the 3D model by simulation with the finite element method.

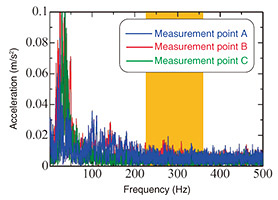

Resonance frequency is unique to the object in question, and when vibrations with that frequency are applied externally to the object, resonance occurs and the vibrations are amplified. According to the results of the simulation, the natural (resonance) frequency of the target maintenance hole was estimated to be in the range of 228.1 to 359.6 Hz. The vibration frequency on site was obtained by measuring vibration acceleration by using acceleration sensors installed at the site, and the obtained acceleration data were converted to frequency by using a Fourier transform. The acquisition interval for the acceleration data was set to 0.1 ms, and the measurement points were the three points used in investigation 1, as shown in Fig. 1. (3) Results of investigation Vibration frequency measured on site when the truck passed by is plotted against vibration acceleration in Fig. 5. According to this plot, vibration frequency is prominent at around 20 Hz at all measurement points (A to C), and almost no vibration was detected in the maintenance hole’s resonance-frequency range (shown in orange in the figure). These measurement results are consistent with the results of similar investigations conducted by TASC as well as with other published results [3, 4].

The above results of investigation 2 suggest that the target maintenance hole does not resonate with traffic vibrations; in other words, it does not affect (amplify) traffic vibrations. 3. ConclusionThe results of investigations on traffic vibration around a maintenance hole were presented. According to these investigations, vibrations exceeding the standards set by the Vibration Regulation Act were not detected near the maintenance hole or at the two nearby locations, and the vibration levels measured at the three locations did not significantly differ. It is also inferred that since the vibration frequency measured at the three measurement points did not match the natural vibration frequency of the maintenance hole, the maintenance hole did not resonate and affect (amplify) traffic vibration. It was thus confirmed that the target maintenance hole is not related to traffic vibrations and does not disrupt the lives of local residents. TASC will continue contributing to solving on-site problems through technical support for those involved in the maintenance and operation of telecommunication facilities. References

|

|||||||||