|

|||||||||||||

|

|

|||||||||||||

|

Feature Articles: Keynote Speeches and R&D on Access Networks Presented at Tsukuba Forum 2025 Vol. 23, No. 9, pp. 33–40, Sept. 2025. https://doi.org/10.53829/ntr202509fa4 Towards New Era of Social-infrastructure Maintenance and Management: Revolution through AI Leveraging and Infrastructure SharingAbstractNTT Access Network Service Systems Laboratories is conducting research and development to solve issues in social infrastructure, such as improving maintenance and management efficiency, enhancing resilience, and reducing environmental impact, aiming for a sustainable society. We, the Civil Engineering Project of NTT Access Network Service Systems Laboratories, aim to innovate infrastructure maintenance and management by advancing the use of artificial intelligence (AI) and incorporating the concept of sharing facilities and data. This article presents our new technologies from the following two perspectives: AI leveraging and sharing in social infrastructure. Keywords: infrastructure, AI, sharing 1. Initiatives of Civil Engineering ProjectNTT is advancing the development of the Innovative Optical and Wireless Network (IOWN) including terminals that can provide high-speed, high-capacity communication using innovative technology focused on optics. NTT is also conducting research and development related to existing telecommunication facilities—such as maintenance holes, conduits, and cable tunnels—that accommodate network cables. This is because NTT must ensure reliability and safety of the communication network, one of the vital social infrastructures that must remain uninterrupted. We, the Civil Engineering Project of NTT Access Network Service Systems Laboratories, have been researching and developing essential technologies related to telecommunication facilities for many years. For instance, we have extensive experience in material analysis and structural analysis for assessing structural strength and reliability. We have also been developing technologies to dramatically improve the efficiency of maintenance and management of facilities. We have been expanding the application of our technologies, which are developed through the construction and maintenance of the telecommunication infrastructure, to other social infrastructures such as electricity and water supply. Our goal is to contribute to addressing societal challenges. 1.1 Common challenges across entire social infrastructureInfrastructure deterioration has become a serious issue in Japan. It causes a rapidly increasing number of large-scale accidents such as tunnel collapses and road subsidence. According to estimates, maintenance costs for infrastructure are expected to increase by approximately 40% by FY2045 compared with those in FY2018 [1]. The working-age population is projected to decline from 77 million in FY2015 to 56 million in FY2045 [2]. These projections suggest a severe shortage of the resources needed to support society. The frequency of severe natural disasters, such as major earthquakes and torrential rains, has also increased. Therefore, not only improving the efficiency of infrastructure maintenance but also enhancing resilience against disasters has become an urgent issue. The telecommunication infrastructure and other social infrastructures share the following commonalities. First, the facilities of these infrastructures are composed of materials such as concrete, steel, and plastic. As the construction ages, deterioration, such as concrete cracking, rebar exposure, and steel corrosion, occurs. Therefore, it is necessary to conduct appropriate inspections and diagnosis and carry out repairs and replacements on the basis of the results. Once an accident occurs, it can have a serious negative impact on daily life. Therefore, it is crucial to effectively detect deterioration that could lead to accidents before it occurs and take preventive measures. However, maintenance work is carried out independently by each infrastructure owner, such as national and local municipalities as well as private companies. This causes redundant inspection and construction activities in the same location, resulting in increased costs and workload. The lack of information sharing and coordinated operations also hinders the optimization of maintenance efforts at the social level. 1.2 AI and sharingThe global artificial intelligence (AI) market is expanding rapidly, and estimates suggested that it will grow 4.4 times over the next five years [3]. The use of AI across various fields is expected to bring numerous benefits since it improves operational efficiency and productivity, reduces cost, enhances customer satisfaction, and addresses labor shortages. Its use in infrastructure is no exception. The concept of sharing—whether it be goods, skills, time, space, or information—has been becoming more common and entrenched in society. This shift enables users to access what they need on a use-as-needed basis. Applying this sharing concept to infrastructure makes it possible to achieve more efficient operations by distributing workloads involved in construction and inspections of facilities. This article introduces our AI technologies for telecommunication infrastructure and their application to other types of infrastructure, and our technologies that contribute to enabling sharing regarding social infrastructure, as shown in Fig. 1.

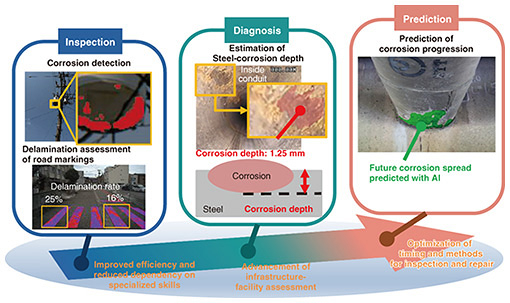

2. Advancing infrastructure maintenance and management through AI leveraging2.1 Inspection, diagnosis, and prediction of deterioration using image recognition AIBy using image recognition AI to assess the condition of infrastructure facilities, conventional visual inspections can be automated. Automating inspections with AI improves efficiency and reduces reliance on individual specialized skills. Figure 2 illustrates our technological progress in streamlining inspection, diagnosis, and prediction of deterioration by leveraging image recognition AI.

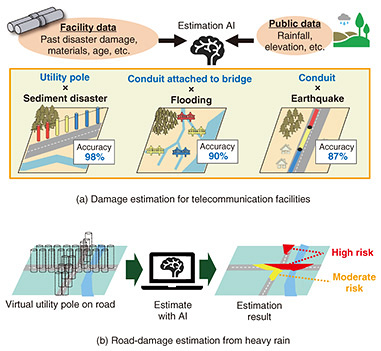

Conventional on-site inspections conducted by field workers requires significant manpower and on-site presence. Human visual inspections often lead to inconsistencies in inspection quality. In contrast, inspection and diagnosis using image recognition AI can mark and visualize the deteriorated areas, such as steel corrosion and paint delamination, on structures, enabling consistent and quantitative evaluation. We have achieved quantification of the corrosion depth of steel materials, which leads to reduced structural strength, from inspection images. Although ultrasonic testing can measure the remaining thickness of steel, it is impractical for large-scale inspections because a probe needs to be placed at the measuring point, which requires much workload for the entire facility. In addition, inspections of large structures, such as bridges, may require the installation of scaffolding and other costs. Therefore, we developed an image-analysis technology that enables the estimation of corrosion depth on steel materials from images captured with drones or pipe-inspection cameras with accuracy equivalent to measurement using ultrasonic waves. We collaborated with Kumagaya City, Saitama Prefecture, to verify a technology for detecting corrosion of steel materials and estimating corrosion depth using images of road bridges captured with drones. We thus successfully achieved a corrosion-detection accuracy of 90% and estimated the steel-section loss due to corrosion with an error margin within 0.67 mm. This technology eliminates the need for conventional ultrasonic equipment. It does not require high-cost inspection using a bridge-specific inspection vehicle or construction of scaffolding, potentially reducing inspection costs by approximately one-fourth. We have also established the world’s first technology for predicting how corrosion will spread over several years. This technology uses a generative adversarial network (GAN), a type of the deep-learning model. We developed a GAN that incorporates elapsed time and corrosion-progression data obtained from past and present images, such as changes in the area, shape, and color of corrosion. This GAN also incorporates multiple environmental factors, such as temperature and precipitation. We thus successfully developed the GAN that can accurately predict the progression speed of individual corrosion spots within the image by inputting infrastructure images, environmental data, and desired prediction year. A field verification was conducted on 20 steel sites on road bridges and telecommunication conduits in Ibaraki Prefecture (excluding coastal areas). The results indicate a correlation coefficient of 0.73 between predicted and actual corrosion-growth rates and an average error of 9.9%, confirming high prediction accuracy. This technology will contribute to optimizing the timing of repairs, reducing maintenance costs, ensuring safety, and smoothing out construction schedules. We plan to launch a service involving this technology for road bridges in FY2025, with future expansion to other social infrastructure and various types of degradation phenomena. 2.2 Disaster-damage estimation for social infrastructure using AI and past data on damage to telecommunication facilitiesWe constructed AI models to estimate the damage risk of several types of NTT’s facilities due to disasters, as shown in Fig. 3(a). We constructed an AI model that estimates sediment-disaster, e.g., landslides, damage to NTT utility poles caused by heavy rain. Utility poles are installed throughout Japan, and there have been confirmed cases of damage due to disasters. This AI model learned utility poles’ inspection data from past sediment disasters and was able to estimate the damage risk with 98% accuracy with test data. We have also constructed a disaster-damage-estimation AI model for telecommunication conduits against earthquakes and bridge-attached conduits against river flooding. We are attempting to apply these AI models to other social infrastructures. For instance, we have developed a foundational technology for predicting road damage during heavy rain, as shown in Fig. 3(b), by adapting our utility-pole damage-prediction AI model to such occurrences. Roads in mountainous areas play a vital role as a support route in the event of disaster. We generally assess the risk of road damage during a sediment disaster by checking the sediment-disaster-risk map to determine which areas are designated as sediment-disaster-prone zones. However, the map mainly focuses on residential areas and does not cover all roads. Evaluating a sediment-disaster risk for a new area, where sediment-disaster-prone zones are not determined, takes time and is costly because it requires a field survey or engineer to read the topographic map. Therefore, we have developed a technology to estimate road-damage risk by considering virtual utility poles at 10-m intervals on a map and estimating each virtual poles’ damage risk with this model. Since this model uses public data, it does not require field surveys and conducts disaster-damage-risk assessments even in areas where sediment-disaster-prone zones are not determined. As a result of applying this model to road damage during heavy rain on the Noto Peninsula in 2024, it was confirmed that the accuracy was equal to or better than that interpreted using sediment-disaster-risk maps.

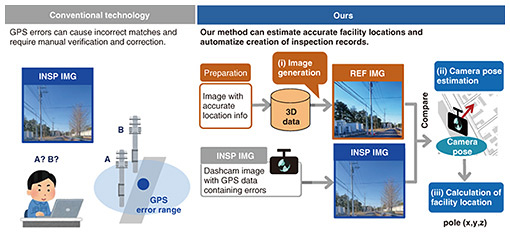

Our earthquake-damage-estimation AI model is being applied to infrastructure design. In conventional communication-route design, area-based risk assessment is carried out using expected properties of an earthquake, such as the peak ground velocity, and topographical information. Locations at risk of disaster are thus confirmed through field surveys, etc. In this case, we tend to rely on experienced employees. In contrast, this AI model can assess quantitative risk on the basis of past disaster damage, enabling us to design a more rational route. By applying these technologies to various social infrastructures and disaster patterns, we aim to contribute to establishing disaster-resistant communities. 3. Advancing sharing in social infrastructureNTT Group is coordinating joint construction initiatives to reduce costs by conducting construction during the same period with other operators when the work is scheduled on the same area. We also collaborate with municipalities, electric-power companies, and gas companies during a disaster. To further expand such inter-operator collaboration in social infrastructure, we are conducting research into technologies that enable the sharing of data and physical assets, i.e., infrastructure facilities. We aim to reduce pre-construction coordination and inspection workload by sharing facility data and inspection data, respectively, thus improving operational efficiency across society. Sharing infrastructure facilities helps avoid redundant capital investment and promotes effective resource use, contributing to a more sustainable social infrastructure. 3.1 Positioning of underground pipelines using 3D dataAs part of the digital transformation of social-infrastructure maintenance and management, initiatives are accelerating to acquire high-resolution spatial data and create accurate three-dimensional (3D) digital models of aboveground facilities. Technologies, such as a global navigation satellite system and mobile mapping system (MMS)*1, are widely used to support these initiatives. In contrast, underground infrastructures present unique challenges since they are buried, e.g., they are not accessible for direct measurement and their location cannot be visually confirmed. Construction records with facility locations for telecommunications, electricity, gas, and water networks are typically managed independently by each infrastructure operator. Therefore, facility design and construction of facilities often require labor-intensive work to cross-reference multiple legacy-construction drawings or conduct trial excavations to verify underground conditions. To improve this situation, cross-sector collaboration and the implementation of a comprehensive digital twin of the underground infrastructure are essential. By promoting the integration of data across utility domains, significant gains in operational efficiency, safety, and resilience can be achieved. With this vision in mind, we are conducting research and development on technologies for accurately measuring and localizing buried infrastructure facilities. Focusing initially on underground telecommunication pipelines, which consist of conduits housing network cables, we have established a method for combining an in-pipe scanning device equipped with a time-of-flight camera and gyroscopic sensor. The scanning device captures point-cloud data along the interior of the conduits, and the point-cloud data are spatially aligned to reconstruct the 3D shape of the full segment. This 3D model of buried facilities is aligned to real-world coordinates using the known positions of maintenance holes as georeferenced references. In experiments using a full-scale mock pipeline setup constructed above ground, the method achieved a positioning error of less than 0.10% over a pipeline measuring 185 m. This method enables the precise determination of pipeline geometry and location regardless of the installation environment. It contributes to reducing field-survey workloads, mitigating excavation risks, and expediting restoration following natural disasters. We plan to expand this solution to pipelines for electricity, gas, and water supply to contribute to a fully integrated digital twin of underground infrastructures. 3.2 Camera pose estimation for 4D infrastructure management systemWe aim to reduce the cost of inspection-data management on the basis of 3D location information for ground-level social-infrastructure facilities, such as power poles, streetlights, and traffic signs. The MMS used by NTT Group for inspecting utility poles and other facilities can acquire inspection data with high-precision 3D location information, but the equipment and MMS costs are high. In contrast, infrastructure inspections using dashcams have become practical due to their low cost and simplicity. However, the Global Positioning System (GPS)-location data with dashcams have significant errors, and linking dashcam-inspection images (INSP IMGs) to the facilities in the management database requires manual work. We are thus developing technology to accurately identify the location of facilities from INSP IMGs, as shown in Fig. 4. We first create 3D data using images with known accurate location information accumulated through NTT’s MMS inspections. Using the 3D data, we (i) render reference images (REF IMGs) and (ii) accurately estimate the shooting position by comparing the REF IMGs with the INSP IMGs. Subsequently, (iii) the facility location is calculated, enabling us to automate the linking of INSP IMGs to the facility information in the database, improving the efficiency of creating inspection records using dashcam inspections. By accumulating inspection data chronologically for each facility location (4D management), we can easily trace and predict the progression of deterioration. This contributes to preventive maintenance by optimizing repair and renewal plans. By using dashcam images from vehicles driving in the area, such as maintenance vehicles and taxis, image data can be collected without driving for inspection. Sharing the inspection data with precise location among multiple infrastructure operators can improve the overall efficiency of operational workflow for social-infrastructure maintenance.

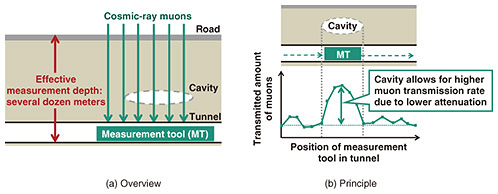

3.3 Shared use of infrastructure assetsBy promoting the shared use of foundational infrastructures, such as conduits and cable tunnels, it becomes possible to reduce new investment and maintenance costs, enabling efficient and sustainable infrastructure operations. This initiative envisions the joint utilization of telecommunication facilities with other infrastructure operators. On the basis of this premise, we are conducting technical studies on housing electric-power and hydrogen-supply facilities within the telecommunication infrastructure. In considering the installation of electric-power cables, three key aspects are being examined. The first is the workability of power-cable installation within telecommunication conduits and maintenance holes. The second involves evaluating the long-term reliability of conduits in high-temperature environments caused by heat generated from power cables. The third concerns the implementation of safety measures, such as grounding measures and countermeasures against leakage and inductive effects, within the telecommunication infrastructure. There is the potential for installing power-storage facilities in the available space of vertical shafts in cable tunnels, which could be used to support resilient power supply to public facilities and evacuation centers during disasters through a community microgrid*2. We are therefore exploring further utilization of telecommunication-infrastructure assets in line with this potential. Improving the efficiency of hydrogen transport is a crucial factor in promoting the use of renewable energy. Therefore, technical studies are also underway on the feasibility of installing hydrogen pipelines within telecommunication conduits. These studies include ensuring the safety of installation and maintenance. For instance, we are considering protection methods for hydrogen-pipeline installation in maintenance holes, cable tunnels, common-use cable tunnels, and bridge-attached conduits. We are also considering methods for monitoring hydrogen concentration to ensure safety during maintenance work in maintenance holes. 3.4 Subsurface-cavity-investigation systemIn civil engineering, accurately identifying the locations of underground installations, such as pipelines, is of vital importance, and extensive research and development has long been devoted to underground-exploration technologies. Road subsidence has become a major social concern in Japan, with approximately 10,000 incidents occurring annually nationwide, including minor cases [4]. Such subsidence events are typically caused by the formation of underground cavities resulting from the outflow of surrounding soil due to failure of buried infrastructure or underground excavation work associated with tunnel and subway construction. Electromagnetic-wave-based methods are widely used for urban subsurface-cavity detection. However, due to the propagation characteristics of electromagnetic waves, these methods are generally limited to a maximum measurement depth of around 2 m. In contrast, the detection of road subsidence often requires probing depths greater than 10 m. To address this limitation, we focus on cosmic-ray muons, which possess high penetrability through the ground, and aim to establish a technology capable of measuring up to several dozen meters underground, as shown in Fig. 5. Muons are a type of naturally occurring radiation with excellent ground-penetration capabilities. Since the muon transmission rate varies according to ground density, measuring variations in the muon transmission rate in subsurface spaces, such as tunnels, enables the detection of cavities above tunnels, which might lead to road subsidence.

By observing subsurface conditions in real time during tunnel-boring operations, it becomes possible to detect cavity formation at an early stage, enabling the prompt identification of risks associated with road subsidence induced by construction activities.

4. Future outlookThis article introduced our research and development in infrastructure maintenance and management that involves AI and incorporates the concept of sharing. Our initiatives are based on NTT’s unique technologies and expertise cultivated through operation of telecommunication-infrastructure facilities over many years. Social infrastructures are facing similar challenges to the telecommunication infrastructure. Therefore, we will further advance our research and development and expand the applications of these technologies and expertise to other social infrastructures, contributing to the resolution of issues across society. References

|

|||||||||||||