|

|||||

|

|

|||||

|

Practical Field Information about Telecommunication Technologies Vol. 18, No. 8, pp. 15–19, Aug. 2020. https://doi.org/10.53829/ntr202008pf1 Snow-accretion-prevention Sheet for Outdoor Aerial ClosureAbstractWhen snow accumulates on closures, it will repeatedly melt and freeze, gradually changing into solid blocks of ice. These ice blocks may fall from closures and damage vehicles below. This article introduces a snow-accretion-prevention sheet that enables snow to fall off closures before it forms ice blocks. This is the fifty-ninth article in a series on telecommunication technologies. Keywords: snow accretion, closure, snow-accretion-prevention sheet 1. IntroductionSnow accretion frequently occurs on overhead equipment during winter in Japan. When snow continues to accumulate on the upper surface of the housing (sleeve) of closures, it will repeatedly melt and freeze, gradually changing into dense hard blocks of ice. These ice blocks may fall from closures and damage vehicles, as shown in Fig. 1. Consequently, in regions with heavy snowfall, maintenance workers have to regularly remove snow from closures to prevent such problems. In such heavy-snowfall regions, measures against snow accretion on closures have therefore become urgent.

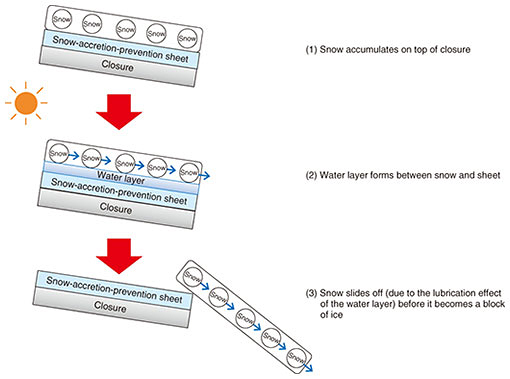

With the above issue in mind, the Technical Assistance and Support Center (TASC), NTT EAST, introduced a countermeasure to prevent snow from accumulating on closures in a previous article [1]. This article presents outline of the technology for preventing snow accretion and the results of a performance verification of the technology involving an outdoor exposure test and describes the procedure for implementing the technology on site. 2. Outline of technology for preventing snow accretionTo prevent snow from accumulating on a closure, a special adhesive sheet with a hydrophilic surface—called a snow-accretion-prevention sheet Nichiban Co., Ltd.—is used, as shown in Fig. 2. When wet snow falls, i.e., snowfall that contains a large amount of moisture, accumulates on the sheet, a water layer forms between the sheet and snow. The lubrication effect of the water layer makes it possible to prevent accidents by making the snow fall from the closure before it becomes a solid block of ice, as shown in Fig. 3. As often seen in regions along the Sea of Japan such as Yamagata and Niigata prefectures, such wet snowfall mentioned above easily attaches to objects [2].

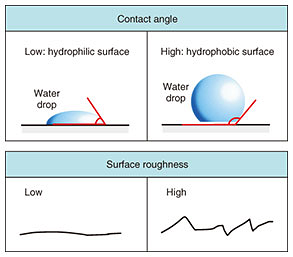

3. Performance verification of the snow-accretion-prevention sheet3.1 Exposure testTo confirm that the performance of the snow-accretion-prevention sheet is maintained even after it is subjected to exposure of natural phenomena such as ultraviolet rays in the summer or wind and rain, including typhoons, an outdoor-exposure test was carried out. The test was conducted in Yonezawa City, Yamagata Prefecture, where heavy wet snowfall often occurs. The verification period of the exposure test was three years, which is the expected quality-assurance period of the sheet. Two verification items were selected: (i) performance parameters (Fig. 4) of the sheet after exposure for three years and (ii) snow-accretion condition based on video images. The contact angle with water, which is one of the indices for evaluating the wettability of a substance’s surface, represents the swelling of a water droplet (i.e., angle of water droplet) that occurs when it is dropped on a substance. A high and a low value indicate a hydrophobic and a hydrophilic surface, respectively. A hydrophilic surface is suitable for the sheet because its hydrophilicity makes it easy to form a water layer between accumulated snow and the sheet. Moreover, low surface roughness reduces the friction between the snow and sheet, making it easier for the snow to slide. During the exposure test, videos of the closures installed at the test site, two with the snow-accretion-prevention sheet and the other without, were recorded to observe the difference in snow accretion due to the presence or absence of the sheet.

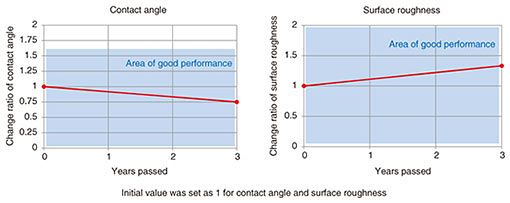

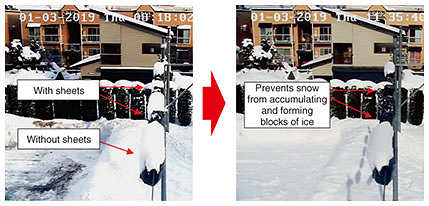

3.2 Test resultsThe rate of change in the performance parameters (contact angle and surface roughness) after the three-year exposure test are plotted in Fig. 5. Under the assumption that the initial values are 1, the performance of the snow-accretion-prevention sheet is maintained when the rate of change of the contact angle is 1.6 times or less and that of surface roughness is 5.0 times or less. Figure 5 indicates that the contact angle and surface roughness remained in the range in which snow-accretion-prevention performance was maintained, even after exposure for three years. In the left photograph of Fig. 6, the same amount of snow accretion was observed on both types of closures (two with and one without the snow-accretion-prevention sheet); however, in the right photograph taken two hours after the left photograph, only the closures with the sheet lost their snow. This result suggests that a closure with the snow-accretion-prevention sheet is more likely to make accumulated snow slide off (thus less likely to cause snow clumping into ice blocks) compared to a closure with no sheet. The above results confirm that the physical properties of the surface of the snow-accretion-prevention sheet (such as contact angle) did not significantly change, and snow falling from the closures was regularly observed during the test period; therefore, the performance of the snow-accretion-prevention sheet was maintained for three years.

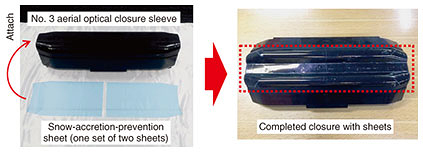

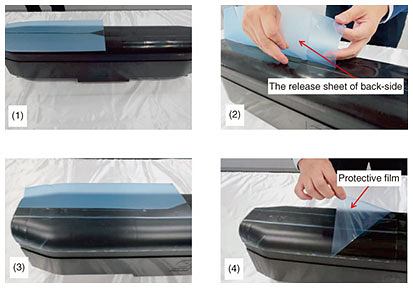

4. Sheet-attachment procedureOne of the advantages of implementing the snow-accretion-prevention sheet is that it can be attached quickly without requiring any particular skill. The procedure for attaching the sheet to a closure is described as follows (see Fig. 7).

(1) Prepare the closure sleeve, snow-accretion-prevention sheet (one set of two sheets), and a cloth for cleaning the upper surface of the sleeve to remove dirt before applying the sheet. Peel off the release sheet along the center line of the back of one snow-accretion-prevention sheet and attach the adhesive side of the sheet to the sleeve (so it will be temporarily fixed). (2) Peel off half of the release sheet from the back side of the snow-accretion-prevention sheet and attach the sheet to the sleeve. Take care not to create irregularities or bubbles when applying the sheet. Repeat for the other half of the surface on the closure sleeve. (3) Attach the other snow-accretion-prevention sheet in the same manner as in steps (1) to (3). (4) Finally, peel off the protective film (blue) on the surface of each sheet (completed closure is shown in Fig. 2). Take care not to directly touch the sheet surface after peeling off the protective film (doing so will reduce the snow-accretion-prevention performance of the sheet). 5. ConclusionThe snow-accretion-prevention sheet can be attached to a closure to allow snow to fall off the closure before it forms an ice block. Thus, it prevents equipment problems and accidents due to snow falling off the closure. An outdoor exposure test confirmed that the performance of the snow-accretion-prevention sheet can be maintained for three years. This sheet can be installed by simply attaching it to the closure. The TASC will continue to promote technical cooperation activities aimed at solving on-site issues and contribute to improving the quality and reliability of telecommunication facilities. References

|

|||||