|

|||||||||||

|

|

|||||||||||

|

Letters Vol. 5, No. 8, pp. 28–32, Aug. 2007. https://doi.org/10.53829/ntr200708le2 Development of New Aerial Optical Cable and Closure that Allow Subsequent Closure InstallationAbstractTo meet the increasing demand for FTTH (fiber-to-the-home) access, we have developed a new aerial 8-fiber cable and a new aerial optical closure. They make it possible for additional closures to be installed after the cable has been installed, so a closure can be placed near a customer's residence after a service order is received. This will lead to more efficient investment and operation.

1. BackgroundThe demand for FTTH (fiber-to-the-home) services has been increasing rapidly and FTTH is expected to become the main type of broadband service in the future. This prediction is supported by recent data showing that the number of new FTTH subscriptions per month has now exceeded that of DSL (digital subscriber line) [1]. To achieve NTT's medium-term business strategy of having 30 million optical access subscribers by 2010, the entire NTT group is working hard to expand optical services. Our R&D section is working on technological developments that will ensure that optical access networks are not only economical, functional, and of high quality, but also available as soon as required. Immediate availability, in particular, will be important in the coming era of full-scale FTTH. 2. Development conceptThus far, on aerial distribution routes where demand is expected to be met by eight or fewer fibers, conventional aerial optical cable with either eight fibers or two 4-fiber ribbons has been used. The conventional optical drop closure was optimized for this cable [2]. The cable and closure structures are simple in order to reduce costs, but closures can be installed only at the same time as the cable. Therefore, some of the closures provided to handle future demand remain unused until a customer living nearby subscribes to an FTTH service. This means that the investment in facilities is underutilized, which is inefficient. In addition, the current closure must store lengths of optical fiber, and cable installation is time consuming. If there is a closure near the subscriber, service order work* can be undertaken promptly. However, if there is no closure, a drop cable must be installed between some telephone poles. This is also time consuming. The conventional access distribution network is shown in Fig. 1.

We have developed a new aerial 8-fiber cable and a new aerial optical closure. They can reduce the initial investment needed for construction, improve optical facility operation, and shorten the required length of drop cable. Our development is based on the following concepts. – Closures can be installed arbitrarily at a later date – Service order work is made quick and easy. – The total cost of equipment and construction is reduced.

3. Aerial 8-fiber optical cables3.1 Conventional cableWith the conventional optical cable, since closures must be installed at the same time as the cable, the cable was designed with the cable part and messenger wire part the same length and integrated together. To extract fibers from a conventional optical cable, a field worker first separates the cable and messenger wire parts and removes an appropriate length of the messenger wire part by using some appropriate tools. Next, he or she uses a conventional tool to separate the sheath over the cable part into two sections. The tool consists of two grippers, which force the two halves apart at the pair of notches, exposing the fibers inside (see Fig. 4). This action bends the fiber, which sometimes causes a temporary increase in its optical loss. 3.2 New cableIf closures are to be installed at a later date, the cable must have excess lengths of fiber that can be extracted with little increase in their optical loss and without interrupting existing services on the network. The new cable structure (Fig. 2) has a spare length in the cable part alongside the messenger wire part. The cable part and messenger wire part are not connected continuously, as in the conventional cable, but only periodically. The cable part has two pairs of notches and two interposed tapes that run along the outside of the fibers. In addition, the tape acts as a barrier that stops cicadas from laying eggs in the cable.

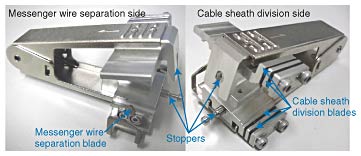

4. Dividing tool for new aerial 8-fiber optical cableWe have also developed a new dividing tool for the new aerial 8-fiber optical cable (Fig. 3). It has two functions: it can divide the cable sheath with little increase in loss and it can separate the cable part from the messenger wire part. This two-sided tool has stoppers that can fix the tool shut, which enables even an unskilled person to divide the sheath. Shutting the tool causes the dividing blade to penetrate the cable. Unlike the conventional tool, the new tool divides the cable sheath into four pieces with almost no bending, and hence little increase in loss. This is achieved by sliding the tool lengthwise along the cable. Moreover, since the tool provides both the required functions, there is no need for a worker to carry two or more tools for this purpose. The conventional and new methods of extracting fibers are shown in Fig. 4.

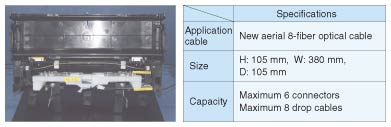

5. New aerial optical closure for new aerial 8-fiber optical cableWe designed the new aerial optical closure to achieve two main goals (Fig. 5) : reduce the service order workload and reduce the total cost of equipment and construction. It has four main features.

The closure installation work is improved because fiber storage work during the installation of a new closure is reduced as much as possible, it is unnecessary for the tension member sheath of the new cable to be removed when a new closure is installed, and all the required parts are assembled in advance. The closure installation time is about 50% shorter than that needed with the previous technique. Because the new cable structure is designed so that the cable part has spare lengths alongside the messenger wire part, the closure can be constructed with the best design (straight type) for later installation and can be installed in response to a customer's request. In addition, by optimizing the parts for the new cable, we made the closure considerably lighter, which enables it to be installed on the single steel messenger wire of the new cable. Moreover, the closure structure is optimized for the use of aerial optical connectors [3]. This simplifies connection and storage work. In addition, the simplification of tension member processing and the assembly of all required parts in advance facilitate construction on a pole.

6. ConclusionThe use of our new cable and closure will facilitate closure installation, provide efficient investment and operation, and simplify the required work. We believe that these developments will make a positive contribution to service order work. In the future, we will develop technologies that are economical, functional, and of high quality that also reduce the time needed for the huge amount of service order work necessary to provide 30 million subscribers with FTTH services by fiscal 2010. References

|

|||||||||||