|

|||

|

|

|||

|

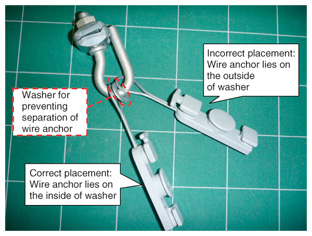

Practical Field Information about Telecommunication Technologies Vol. 11, No. 12, pp. 45–49, Dec. 2013. https://doi.org/10.53829/ntr201312pf1 Enhancing the Reliability of Aerial Iron Fittings (Span Clamps and Outdoor Wire Anchors)AbstractIn this article, we introduce how to enhance the reliability of aerial iron fittings (span clamps and outdoor wire anchors). This is the twentieth in a bimonthly series on the theme of practical field information on telecommunication technologies. This month’s contribution is from the Materials Engineering Group, Technical Assistance and Support Center, Maintenance and Service Operations Department, Network Business Headquarters, NTT EAST. Keywords: countermeasure, corrosion, telecommunication facilities 1. IntroductionDespite the coming of the optical era, metal, concrete, plastic, and other materials are still being used in telecommunication facilities. In the Materials Engineering Group, we are exploring the causes of failures unique to these facilities that have been brought on by the deterioration of these materials and are working to prevent the reoccurrence of such failures. In this article, we present a case study of corrosion promotion peculiar to coastal areas in span clamps and outdoor wire anchors (aerial iron fittings) used in telecommunication facilities, and we introduce products to counter such corrosion-based deterioration. 2. Problems in span clamps and outdoor wire anchors leading to hanging drop linesA span clamp and outdoor wire anchor are needed to drop an NTT telecommunication cable into a customer’s home. If a span clamp should come apart from a messenger wire or a self-supporting type of telecommunication cable, or if an outdoor wire anchor should come apart from the span clamp, the drop line will hang loose, which will create a facility fault. A loose-hanging drop line can then come into contact with passing pedestrians or vehicles and cause an accident. It is therefore necessary to prevent such accidents by ensuring that these components do not separate from the equipment. The separation of a span clamp or outdoor wire anchor can be caused by (1) loosening of the nut on the span clamp, (2) incorrect placement of the separation-prevention washer (Fig. 1), or (3) corrosion and subsequent deterioration of an iron fitting. Conditions (1) and (2) can be prevented by properly installing the components, but deterioration caused by corrosion (3) cannot be prevented by proper installation work alone.

3. Case study of corrosion and deterioration in span clamp and outdoor wire anchorThe main components of a span clamp are (1) support plates, (2) a hook bolt, (3) an anti-separation washer, and (4) a nut (Fig. 2). Support plates are made of zinc alloy, but components (2)–(4) are made of steel with zinc plating applied to their surfaces. Since zinc is more resistant to corrosion than steel (iron), the zinc-alloy support plates as well as the other components plated with zinc are thought to be sufficiently resistant to corrosion provided that they are not located in environments that are particularly conducive to corrosion such as areas with briny air or hot springs.

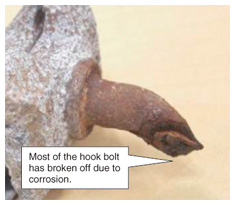

A rusted and broken span clamp is shown in Fig. 3. It was left at a location in a coastal area where a drop line was hanging loose. This span clamp had been installed about 20 years earlier. It can be seen that the hook bolt is highly corroded and that most of it had broken off. The diameter of the hook bolt was approximately 9 mm, and its surface had originally been plated with a layer of zinc approximately 30 μm thick. Simulations done using commonly reported corrosion speeds for zinc plating and steel in coastal areas*1 reveal that it would take about 50 years for corrosion to advance from the zinc-plating layer to a level deep enough to make the hook bolt break away. However, as stated above, this span clamp with the broken hook bolt had been installed only about 20 years earlier. Therefore, we continued our investigation in order to find the cause of this accelerated speed of corrosion in steel.

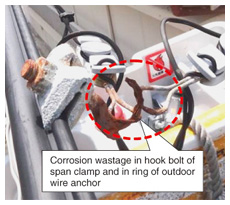

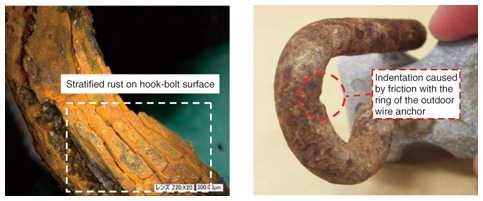

A corroded span clamp and outdoor wire anchor are shown in Fig. 4. These were installed in the same area as the above span clamp whose hook bolt broke off due to corrosion. Here, the corrosion has not yet reached the point at which the hook bolt would break off, but it is clear that the span clamp and the ring fitting of the outdoor wire anchor are in a state of significant corrosion. Fragile, stratified rust covers the surface of the hook bolt, and a friction indentation can be seen at the point where the bolt comes into contact with the ring of the outdoor wire anchor (Fig. 5). A hook bolt that is not corroded has a cylindrical shape that causes rainwater or airborne sea salt to run off it, preventing it from collecting on the surface of the hook bolt.

However, if stratified rust should form on the surface of the hook bolt, water that contains salt—a corrosion-promotion factor—will collect and possibly lead to corrosion (Fig. 6). In addition, fragile, stratified rust can easily suffer from frictional wear due to friction between the bolt and the ring of the outdoor wire anchor. We therefore concluded that the generation of fragile, stratified rust and the frictional wear caused by friction with the corroded ring of the outdoor wire anchor were factors that most likely caused the hook bolt on the span clamp to break off about 20 years after installation.

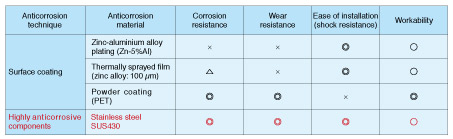

4. Study of countermeasure productsAs stated above, two factors are the main causes of the hook bolt breaking away from the span clamp: corrosion-induced deterioration of the material itself and frictional wear caused by friction between the hook bolt and the ring fitting of the outdoor wire anchor. With the aim of preventing the reoccurrence of such problems, we investigated ways of improving the corrosion resistance and abrasion resistance of span clamps and the ring fitting on outdoor wire anchors. We also took construction costs into account and set two conditions: (1) any enhanced products must be just as easy as existing ones to install, and (2) they must be manufacturable using nearly the same process as existing products. Specifically, we began by examining anticorrosion specifications that could be achieved by using a method for which manufacturing costs would not be greatly different from that of existing products. From that examination, we decided to investigate two types of countermeasures: anticorrosion techniques using a surface coating, for which anticorrosion could be achieved in existing products in a post-manufacturing process, and highly anticorrosive components using highly anticorrosive materials that could be manufactured on the same manufacturing line as existing products. First, for the anticorrosion countermeasure using a surface coating, we prepared three prototype anticorrosion surface coatings by (1) using zinc-aluminium alloy plating, (2) thickening a surface zinc coating by thermal spraying, and (3) using a powder coating made of polyethylene terephthalate (PET) resin. Next, for the anticorrosion measure by using highly anticorrosive components, we prepared a prototype product using stainless steel (SUS430). We then evaluated the characteristics of each of the above prototype products in order to find the product with the best corrosion resistance, frictional-wear resistance, and ease of installation. The results are listed in Table 1.

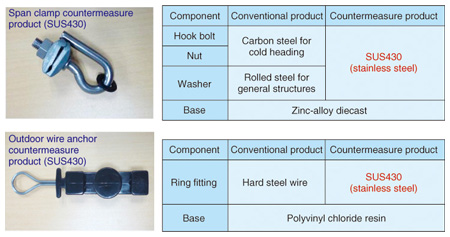

We concluded from the evaluation that the prototype product using stainless steel components (SUS430) rather than the conventional material gave superior results. A comparison of component quality between conventional products and the proposed countermeasure products is shown in Fig. 7. The washer of the span clamp and the base of the outdoor wire anchor of the countermeasure products are black to increase their visibility to maintenance personnel.

5. ConclusionCorrosion of components used for telecommunication facilities can easily progress in certain regions such as coastal areas. We introduced a case study of deterioration in which the hook bolt of a corroded span clamp broke off due to friction with the ring fitting of an outdoor wire anchor. To prevent the reoccurrence of such deterioration, we improved the corrosion resistance and abrasion resistance of conventional span clamps and outdoor wire anchors, thereby achieving products with long-term reliability. Span clamps and outdoor wire anchors are components that are not recorded in design drawings, which make them difficult to maintain and inspect. At the same time, as facility maintenance personnel age and subsequently retire, their numbers in the years to come will most likely decrease, as it is expected to be difficult to replace all of them because of the declining population. The need is therefore strong for maintenance-free facilities. At the NTT EAST Technical Assistance and Support Center, we plan to conduct studies on efficiently maintaining and managing not only aerial iron fittings but underground iron fittings too. |

|||