|

|

|

|

|

|

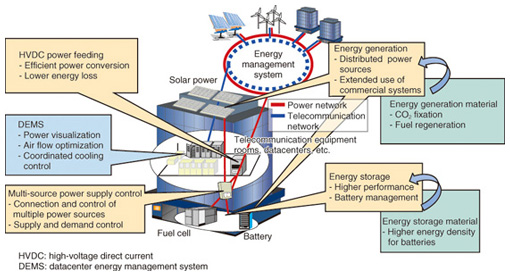

Feature Articles: Current Status of Technology Development Toward Energy-saving––For Continuous Telecommunications Infrastructure Connections 24/7 Vol. 12, No. 3, pp. 11–18, Mar. 2014. https://doi.org/10.53829/ntr201403fa2 Power Supply and Air Conditioning Technologies for Sustainable Telecommunication InfrastructureAbstractImproving the energy efficiency of telecommunication equipment rooms and datacenters, which account for much of the power consumed in the NTT Group, is important for both the global environment and reducing electric power costs. This article describes recent discussions held by the Energy and Environment R&D (research and development) Committee and recent R&D on power supply and air conditioning technologies intended to achieve a sustainable telecommunication infrastructure. Keywords: HVDC power feeding, air-conditioning control, energy material 1. IntroductionThe NTT Group is conducting research on energy conservation of network facilities. We present some recent research and development (R&D) activities relating to technologies on power saving for power supply and air conditioning systems. NTT Energy and Environment Systems Laboratories has previously developed a low-energy-loss high-voltage direct current (HVDC) power feeding system and is moving forward with achieving further energy savings in telecommunications equipment rooms and datacenters through more advanced energy management of power feeding systems, air conditioning systems, and information and communications technology (ICT) equipment. Telecommunications services are part of the basic social infrastructure and must be sustainable even during disasters. Together with the development of technology for controlling multi-source power supplies and systems for creating and storing energy (fuel cells, batteries, etc.) to achieve a stable power supply, we are promoting medium- and long-term R&D on next-generation materials for energy creation and storage systems (Fig. 1).

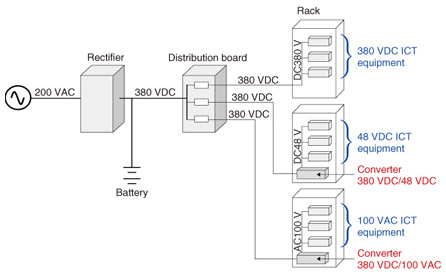

We introduce three R&D activities in the following sections. First, we describe practical trials on an HVDC power feeding system that is ready for commercial use. The trials were conducted in an actual operating environment. We then present the most recent work on datacenter energy management systems, including the use of virtualization software for optimizing ICT load arrangements and air conditioning system operations. Finally, we introduce studies on next-generation materials for energy creation and storage designed to reduce power costs and power outages into the future. 2. Actual-operation trials for HVDC power feeding systemThe development of the HVDC power feeding system has been completed, and the system is now ready for commercial use. Sales of ICT equipment operating on 380 VDC (voltage direct current) have begun, but it will remain necessary to supply power to existing 48-VDC or 100-VAC (voltage alternating current) ICT equipment until the high-voltage equipment comes into widespread use (Fig. 2). In response to this requirement, we have been conducting machine room trials in a telecommunications building with a view to introducing in the NTT Group an HVDC power feeding system that incorporates a converter for converting 380 VDC to 48 VDC or 100 VAC. These trials involve evaluating the overall performance and reliability of power feeding systems that include converters, and designing and investigating various methods of construction, operation, and maintenance.

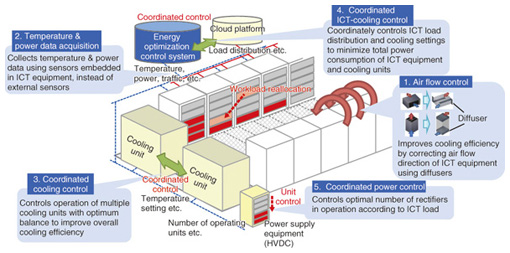

NTT Energy and Environment Systems Laboratories is mainly responsible for evaluating the overall power feeding system performance and reliability. The performance evaluation involves testing for efficiency, voltage accuracy, and noise level, and verifying robustness in actual operation. Because sudden changes in power can be expected in actual operation, the evaluation includes examining the continuity in ICT equipment operation in a dynamic environment when 1) commercial power outages and restorations occur, 2) inrush current occurs when equipment is turned on, 3) fluctuations take place in ICT equipment power consumption, and 4) short circuits occur in ICT equipment input. The reliability evaluation includes calculating the overall power feeding system reliability from the failure rates of individual equipment components and evaluating how the inclusion of converters affects overall system reliability. We performed these various evaluations, clarified what items need attention when a system is constructed, and made proposals to improve the power feeding system for actual operation. In future, NTT Energy and Environment Systems Laboratories will conduct further R&D to improve the efficiency of power conversion equipment. We will also provide companies with technical support for system introduction and cooperate with vendors to expand the lineup of 380-VDC ICT equipment to promote widespread use of the HVDC power feeding system. 3. Towards energy-efficient telecommunication machine rooms and datacentersICT equipment, cooling units, and power supply equipment account for the majority of energy consumed in telecommunication machine rooms and datacenters. Thus, overall optimization of all three components is essential for saving energy. NTT Energy and Environment Systems Laboratories has been researching and developing optimal energy control technology that is aimed at reducing the energy consumed in telecommunication machine rooms and datacenters (Fig. 3). Specifically, R&D is underway on the following technologies: air flow control technology to prevent local temperature increases and achieve efficient cooling; data acquisition technology using embedded sensors of ICT equipment to collect temperature and power consumption data without using external sensors; coordinated cooling control technology that optimizes the settings of multiple cooling units for balanced and efficient operation; coordinated ICT-cooling control technology that optimizes the setting of cooling units and load distributions of ICT equipment to minimize the total power consumption of the ICT equipment and cooling units; and power supply unit control technology that optimizes the number of operating units of power supply equipment according to the operating level of ICT equipment.

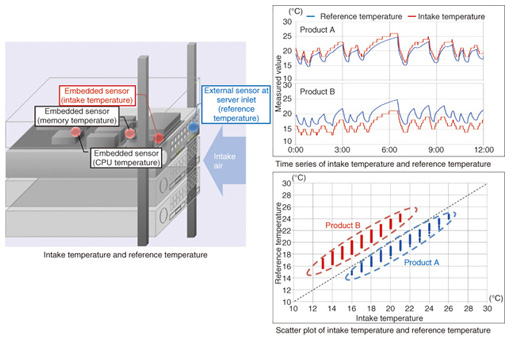

3.1 Temperature and power data acquisition technology using embedded sensors in ICT equipmentMonitoring of room temperature distribution and equipment power consumption is necessary to make telecommunication machine rooms and datacenters more energy efficient. Such monitoring data are generally collected by installing external sensors, but the cost of these sensors and their installation can be a problem when measurements are taken in many places. ICT equipment has built-in sensors for monitoring equipment states such as CPU (central processor unit) temperature, voltage, and fan speed. Using these embedded sensors instead of external ones would greatly reduce costs. An investigation was conducted on the use of embedded sensors to acquire intake temperature and power consumption of commercial servers produced by multiple manufacturers. The results revealed problems concerning the data acquisition interface and the accuracy of the acquired sensor data. Regarding the interface, nearly all of the servers enabled acquisition of intake temperature and power consumption sensor data via the IPMI (intelligent platform management interface), but the IDs (identifications), quantity, and location of sensors differed from product to product. We are using the results of the investigation to promote standardization of the data interface and dissemination of compatible equipment. In evaluating the accuracy of the sensor data for the intake temperature, a difference was found between the embedded sensor data and the reference temperature measured at the air intake side, and this difference varied among products (Fig. 4). Future tasks will be to promote the standardization of sensor accuracy requirements and investigate technology for eliminating variations among products by correcting the sensor data.

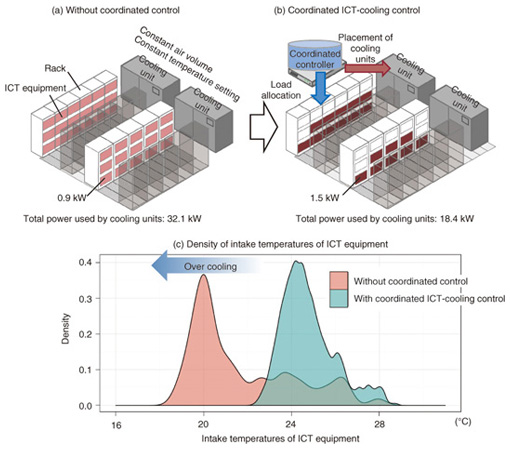

3.2 Coordinated ICT-cooling controlCooling units in telecommunication machine rooms and datacenters are operated with a margin so that the intake temperature of ICT equipment does not exceed the upper limit for reliability concerns. ICT equipment is often operated with a focus on processing efficiency, with less consideration given to ease of cooling by cooling units. Cooling would be more efficient if it were possible to allocate load to ICT equipment located in areas where the cool air supplied by cooling units can easily reach. In recent years, such dynamic and flexible load allocation has become possible through live migration of virtual machines. Therefore, we have been working on coordinated ICT-cooling control technology with the objective of reducing the power consumed by ICT equipment and cooling units. We have developed a method of coordinately controlling the setting of cooling units and the load distribution of ICT equipment and a method of efficiently solving the optimization problem for the control in order to minimize the total power consumption while maintaining the intake temperatures of ICT equipment below upper limits. We present here experimental results to demonstrate the reduction in power use by cooling units using the coordinated ICT-cooling control. The case in which the load distribution on ICT equipment is uniform and the setting of cooling units is controlled so that the intake temperatures of ICT equipment do not exceed the upper limit (i.e., without coordinated control) is presented in Fig. 5(a), and that in which the load distribution is optimized by the coordinated ICT-cooling control is presented in Fig. 5(b).

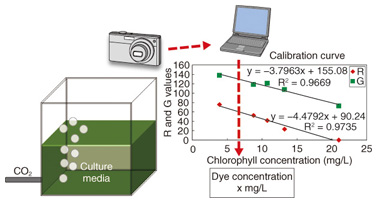

The results verify that coordinated ICT-cooling control technology can reduce the power consumed by cooling units by 42%, while satisfying intake temperature constraints. In future, we plan to proceed with the development and verification testing of optimal control algorithms implemented in an actual cloud environment. 4. Next-generation material technology for key component of energy generation and energy storage systemsOur medium- and long-term R&D efforts in energy production and energy storage include conducting research on next-generation materials for creating key materials and components of energy generation and energy storage systems. 4.1 Highly efficient CO2 fixation by algaeWe are focusing on green energy technology involving green fuels, green power generation, and carbon dioxide (CO2) fixation-and-fuel-reproduction in order to reduce dependence on fossil fuels and to lower energy costs. Part of this research involves looking at the price fluctuations and cost risk of CO2 emissions. We introduce here technology for achieving highly efficient CO2 fixation (which refers to, for example, photosynthesis) by using algae for CO2 fixation-and-fuel-reproduction. There is enormous biodiversity in algae, especially microalgae, and they have very beneficial features, including 1) a much higher multiplication rate than that of terrestrial plants (population doubling time of a few hours), 2) ten times higher CO2 fixation volume per unit area than that of a forest, and 3) a high lipid content. These features have drawn attention to the use of microalgae as a fuel resource that does not compete with food resources. However, in the search for optimized cultivation conditions, advanced analysis is necessary. This analysis requires preprocessing using methods such as optical density or high performance liquid chromatography to quantify the amount of dyes (chlorophyll etc.), which correlates with photosynthesis activity and with the cell concentration and total amount of organic carbon, which are required for evaluating the amount of CO2 fixation. We therefore focused on an easily implemented (and real-time, non-destructive) technique for quantifying microalgae dye from the RGB (red, green, blue) values of a digital camera image. We have established a technique that can approximate the correlation between the RGB values of a digital camera image and the dye (chlorophyll) concentration in culture media with a linear function (Fig. 6). This simple and real-time image analysis enables us to estimate cell densities or growth rates of microalgae nondestructively by using a low-cost commercial digital camera. We plan to apply this technique in the future in the search for cultivation conditions that lead to highly efficient CO2 fixation.

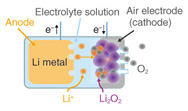

4.2 Li-air battery technologyOur research on energy storage has focused on high-energy-density battery technology with the medium- and long-term objectives of improving robustness against power outages and increasing the use of solar and wind electrical power generation for natural (renewable) energy. We explain lithium-air (Li-air) battery technology for achieving a ten-fold increase in the energy density of Li-ion batteries, which have the highest energy densities of widely used secondary batteries. The Li-air battery consists mainly of an air electrode (cathode), electrolyte, and anode (Fig. 7). Our objective is to improve the performance of the air electrode, which plays an important role in battery reaction and largely governs battery performance. The air electrode contains the reaction sites between Li ions and oxygen in air, so a function for passing oxygen while preventing electrolyte leakage is needed. The reaction site is highly activated by using a RuO2 (ruthenium oxide) catalyst for the air electrode in combination with a dimethyl sulfoxide electrolyte. As a result, both the charging and discharging capacity increases to about 1000 mAh/g, and the charge-discharge voltage difference decreases to about 0.7 V.

Secondary battery performance is generally evaluated in terms of capacity discharging, charge-discharge efficiency, and number of charge-discharge cycles. Previous research has focused on improving performance in these areas. In the future, we will work on improving techniques for preventing electrolyte leakage and improving oxygen permeability, which is thought to be linked to increasing the number of charge-discharge cycles, and we will also search for materials to optimize the air electrode structure. 5. Future workIn line with discussions held by the Energy and Environment R&D Committee, we will strongly promote R&D in power supply and air conditioning technologies for reducing the cost of electric power and enhancing the tolerance of the telecommunication infrastructure against power shortages. |

|