|

|||||||||

|

|

|||||||||

|

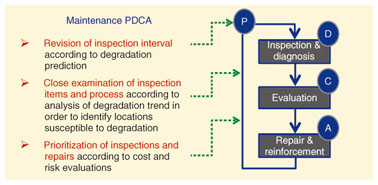

Feature Articles: R&D on Maintenance and Management Technologies for Telecommunication Infrastructure Vol. 12, No. 10, pp. 11–16, Oct. 2014. https://doi.org/10.53829/ntr201410fa2 Facilities Management Technology for Optimizing Inspection and Repair TimingAbstractThe huge number of telecommunication infrastructure facilities that support information technology services continues to deteriorate from aging, and the number of technicians available to conduct maintenance is decreasing, so maintenance and management methods that are both practical and economical are needed. To meet this need, we are carrying out research and development on facilities management technology for setting inspection and repair criteria according to the state of each facility as determined by degradation prediction. This article describes our work on facilities management technology and our maintenance and management methods for manhole inspection. Keywords: infrastructure facilities, maintenance and management, degradation prediction 1. Facilities management technology1.1 Background and problemsFacilities management technology provides maintenance and management criteria and methods for the efficient management of the Plan-Do-Check-Act (PDCA) cycle as a series of maintenance tasks that includes facility inspection, diagnosis, repair and reinforcement, and maintenance planning (Fig. 1). The ceiling collapse in the Sasago Tunnel in 2012 heightened concerns about infrastructure safety within Japan, and infrastructure maintenance and management efforts have since increased further in importance. However, various challenges arise in terms of maintenance. The maintenance of telecommunication infrastructure facilities involves three particular problems: (1) Facilities are aging, and the number of maintenance technicians is decreasing; consequently, the efficiency of maintenance work must be increased in order to cope with these issues. (2) The current uniform management criteria must be revised, and a management method that can deal with individual cases of degradation that arise according to installation conditions and other factors must be developed. (3) There is a need for cooperation with the managing authorities of the roads under which facilities are installed and with other companies that install underground infrastructure elements.

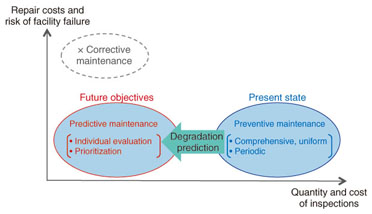

We are working on a plan for maintenance and management of telecommunication infrastructure facilities based on preventive maintenance, in which inspections are done and measures are taken before problems occur. To avert the risk of facility failures, preventive maintenance involves uniform, comprehensive, and periodic inspections of all facilities and the implementation of repairs and renovation as needed. However, the cost and labor required simply to inspect the huge number of aging facilities alone is very high. To deal with that problem, we are aiming to optimize the timing of inspections and repairs based on an evaluation of the state of individual facilities and on predictions of their eventual degradation (Fig. 2) [1]. That requires technology for understanding the degradation mechanism and for prediction of degradation, and technology for evaluating degradation and residual strength.

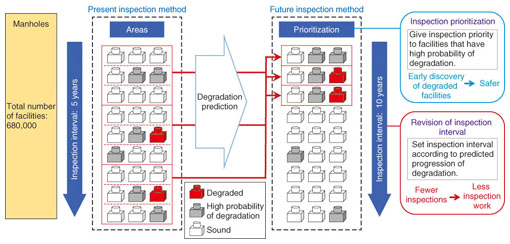

1.2 Features of telecommunication infrastructure facilitiesManholes and tunnels are constructed of steel-reinforced concrete. Past research on the degradation mechanism of concrete structures and research on maintenance and management methods has mainly focused on roads and railway structures, and much knowledge has been obtained. Compared to roads and railway structures, telecommunication infrastructure facilities are small, individual structures that all have roughly the same specifications. Because the facilities are buried underground, the environmental conditions are more limited than those of outdoor structures. Also, the number of facilities is huge. For these reasons, it is important to identify methods that are particularly suited to telecommunication facilities as we review research on road and railway structures. Manholes are currently the facilities that are most numerous and that require a substantial amount of inspection work. We are working on a maintenance and management method that takes the features of manholes into account. 1.3 Cooperation with other infrastructure enterprisesIn addition to referring to past research on roads and railway structures, our research and development (R&D) on maintenance and management methods includes exchanging ideas on inspection work with other infrastructure management authorities and enterprises. As part of that, we are participating in the Research Initiative for Advanced Infrastructure with ICT (information and communication technology) offered by the University of Tokyo Interfaculty Initiative in Information Studies [2]. In addition to conferring with infrastructure enterprises such as the East Japan Railway Company, Tokyo Metro Co., Ltd., and the Metropolitan Expressway Company Limited as well as with university scholars, we are engaging in discussions on the sharing and analysis of problems related to infrastructure management and the proposal of improvement and operation methods. The research initiative involves analyzing some of the inspection data obtained using the manhole inspection prioritization technology. Also, NEXCO East Japan (East Nippon Expressway Company Limited) and the Tokyo Electric Power Company, Incorporated (TEPCO) will join the initiative in 2014. TEPCO also manages manholes and other facilities of the same types managed by NTT, so we expect even more fruitful activities. 2. Manhole maintenance and management methodsNTT has about 680,000 manholes throughout Japan, and about 80% of them are at least 30 years old. Some are beginning to show deterioration from aging, which will continue in the future, so early discovery of degraded facilities and appropriate maintenance are required. Currently, manhole inspection is done area by area at a uniform inspection interval for all facilities. However, manhole degradation does not occur consistently with the age of the facility, but varies with the installation environment and structure. Our objective for the future is to apply practical inspection timing in which the progression of degradation is predicted for each manhole and inspections are performed with priority given to facilities that have a high probability of degradation, while the inspection interval is extended for other facilities (Fig. 3).

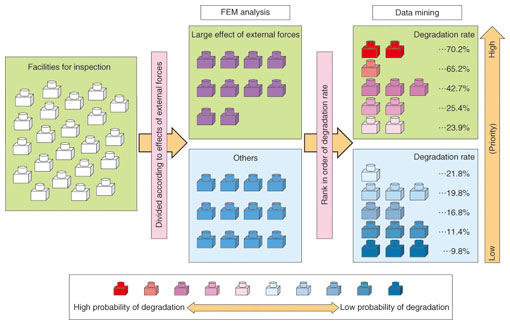

2.1 Manhole inspection prioritization technologyWe used FEM (finite element method) analysis* to clarify the relation between outside forces that act on the facilities and the installation environment, and cracking that occurs inside manholes. We used the results to analyze existing inspection data in order to identify the inspection items and installation conditions on which an inspection judgment of degraded is based. The result is that we were able to determine which facilities have a high degradation probability [3]. First, facilities are sorted according to whether or not they are in installation environments where the effect of external forces may cause cracking. The data are then analyzed in order to classify the facilities according to the probability of degradation. Manholes that are subjected to large external forces and have a high probability of degradation can then be given priority in inspection (Fig. 4).

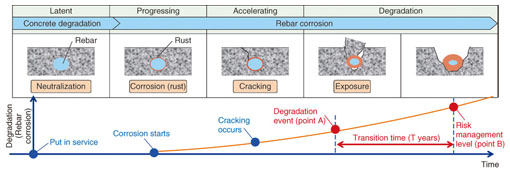

We analyzed about 20,000 inspection data values and assigned priorities for the 7600 manholes to be inspected in the future. In 2013, about 2700 inspections were done, largely in order of priority. The degraded facility discovery rates (number degraded/number inspected) were 9.5% for all of the inspection data collected so far, 14.2% for the prioritized facilities, and 13.3% for the actual inspection results. In the actual inspections, too, the discovery rate was higher than previously obtained by a factor of from 1.4 to 1.5, close to what was expected. The former area-based inspection scheme allowed efficient setting of inspection routes. Inspection sites selected according to priority, however, might be scattered over a wide area, making inspection work inefficient. In practice, however, manholes that have relatively high repair priorities tend to be clustered together, so there was no actual decrease in efficiency due to inspection routing. The results described above confirm both the practicality of this method for actual inspection work and the effectiveness of early discovery of degraded facilities. 2.2 Revision of manhole inspection intervalCurrently, the manhole inspection interval is about five years, but it is desirable to set the interval so that it matches the progression of manhole degradation. We therefore proposed a method of setting the manhole inspection interval based on the level of rebar corrosion risk determined according to an understanding of the manhole degradation process obtained by observing the progression of rebar corrosion within the concrete. The process of degradation by rebar corrosion in ordinary steel-reinforced concrete structures is illustrated in Fig. 5. There are four levels of risk: latent, which is prior to the beginning of rebar corrosion; progressing, in which rebar corrosion has begun but no degradation is apparent on the surface of the concrete; accelerating, after cracking has appeared; and degradation, where concrete has actually separated or fallen off, and protection of the rebar is compromised. Point A is where degradation can be confirmed visually, point B is the rebar corrosion state that determines the risk level, and T (years) is the time for the transition of rebar corrosion from point A to point B. To detect point A by inspection before point B is reached, the inspection interval must be set to T years or less. That is to say, if the state at the time of the inspection is before point A, point B will not be reached after T years with no measures taken at the time of the next inspection. If degradation of point A or later is confirmed at the time of the periodic inspection, the arrival at point B at the time of the next inspection T years later can be prevented by undertaking some repairs or other measures.

Data from past studies and the results of further on-site investigations show that if point A is taken as the point of rebar exposure and point B as the criteria for required repair of cut-and-cover tunnels, the transition time from point A to point B (T) with a rebar corrosion rate of 15% is about 10 years. Because ‘exposed rebar’ is a phenomenon that can be confirmed visually, the inspection can be done without a great change in the conventional inspection work flow. These results suggest that the current inspection interval of five years can be extended in order to increase the economy of inspections. (The results for this finding were obtained in June 2014.)

3. Future developmentOur future work on maintenance and management methods for manholes will aim to improve the accuracy of predicting the degradation progression that takes into account the environmental conditions of individual manholes. We also plan to investigate the extension of these methods to tunnels and other facilities. Although the studies of maintenance and management methods have assumed periodic visual inspections as currently done, future R&D on facilities management technology will build on trends in inspection technology in which other techniques are applied. References

|

|||||||||