|

|||||||||||

|

|

|||||||||||

|

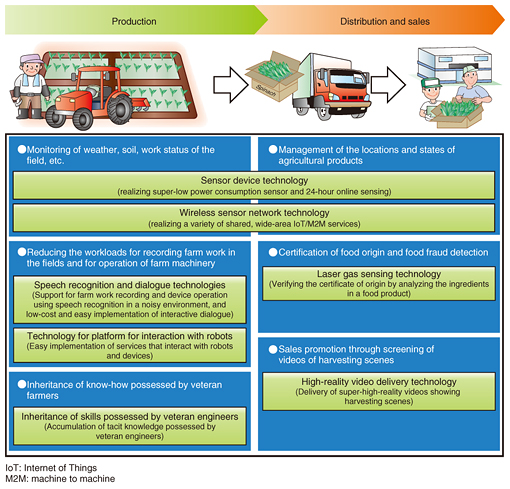

Feature Articles: NTT Group Activities in the Agricultural Field Vol. 14, No. 6, pp. 27–34, June 2016. https://doi.org/10.53829/ntr201606fa5 Research and Development Activities Related to AgricultureAbstractNTT is undertaking research and development (R&D) on the application of information and communication technology in new business fields including agriculture. This article introduces three agriculture-related R&D activities exhibited at AGRINEXT 2015, which was held October 14–16, 2015 at Makuhari Messe: a farm work recording solution using an intelligent microphone and the VoiceRex speech recognition engine; a cloud-based pallet management system using the 920-MHz band; and laser gas sensing technology using laser light sources that NTT has developed to detect food labeling fraud. Keywords: co-innovation, sensor network, speech recognition 1. IntroductionA number of NTT technologies can be applied to agriculture. They include 1) sensor device and wireless sensor network technologies that can be used to monitor weather and soil conditions relating to specific areas of farmland, 2) technologies that assist in reducing the workload for keeping farm work records and/or operating agricultural machinery, and 3) technologies that manage product distribution or verify the authenticity of production districts. NTT is carrying out research and development (R&D) aimed at commercializing these technologies (Fig. 1). This article introduces three such technologies that were exhibited at AGRINEXT 2015.

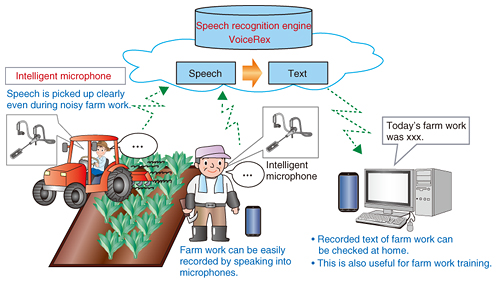

2. Farm work recording solution using intelligent microphone and VoiceRex speech recognition engineWe describe here an agricultural solution using an intelligent microphone in conjunction with NTT’s VoiceRex speech recognition engine. 2.1 Overview and features of this technologyJapanese agriculture is facing three serious issues: the aging of the farming workforce, a shortage of young persons with aspirations to become farmers, and an increase in the area of abandoned farmland. The combination of these situations prompted a revision in 2009 to the Agricultural Land Act, newly allowing general corporations to enter the agricultural industry. As a result, the number of agricultural corporations has been on the rise. Perceiving an urgent need to improve efficiency in farm work and raise the quality of farm products, agricultural corporations are shifting from farm management based on intuition, experience, and memory to an approach that relies on keeping daily farm work records and analyzing the recorded data. NTT Media Intelligence Laboratories has developed a solution that enables farmers to record information about their farm work using speech input so that they do not have to take time out from their work. This solution was exhibited at AGRINEXT 2015. It combines an intelligent microphone [1], which can clearly pick up sound even in very noisy environments, with a highly accurate speech recognition engine called VoiceRex (Fig. 2).

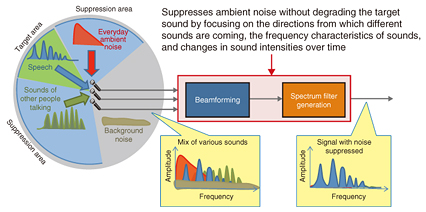

(1) Intelligent microphones Intelligent microphone technology uses acoustic signal processing that discriminates between ambient sound (noise) and the target sound, which it separates with a high degree of accuracy. This processing focuses on the directions from which different sounds are coming, the frequency characteristics of sounds, and changes in sound intensities over time (Fig. 3). With conventional technologies, it is difficult to suppress a loud noise without degrading the target sound. The new technology can reduce the surrounding noise to about one ten-thousandth the actual level while maintaining the integrity of the target sound. Thus, the target speech can be recognized with a high degree of accuracy, even amid an overall noise level of 100 dB. Since this technology can work with only two or three microphone elements, the intelligent microphone device can be made compact.

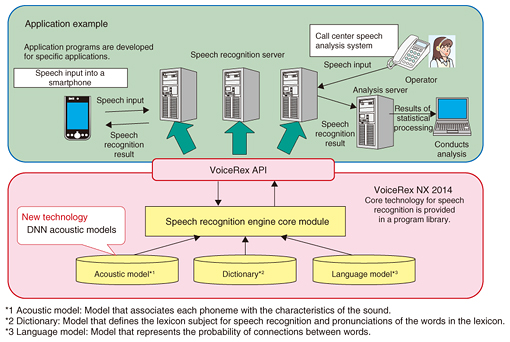

(2) VoiceRex VoiceRex is a highly accurate speech recognition engine based on a deep neural network (DNN) (Fig. 4), which simulates information processing that occurs inside the human brain. Speech recognition requires pre-registration of the words. VoiceRex is a continuous speech recognition technology that covers a very large vocabulary, allowing up to 10 million words to be registered as a dictionary. Almost all regularly used words are already registered. VoiceRex can be adapted to a wide range of applications by enabling the addition of words that are specific to any particular field such as the names of farm machinery in the case of an agricultural industry application.

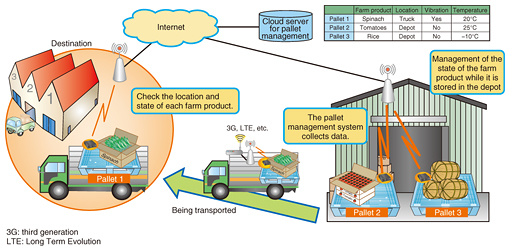

2.2 Assisting in recording farm workConventionally, farmers have recorded farm work after returning to their offices and sitting in front of a computer, or have used their smartphones to text the information to their computers while working in the fields. Inputting data at the end of the day is problematic because it is easy to forget details, and some farmers are likely to be reluctant to spend time on a computer after a hard day on the farm. VoiceRex enables farmers to input information by speaking the information aloud as they work. Because the details are input on the spot, more accurate information can be recorded. However, voice recording of information in the field can be difficult due to the loud noise generated by farm machinery. The intelligent microphone solves this problem. It enables the farmer to input spoken data even while driving a roaring combine harvester or tractor. Information can be input efficiently without the need to interrupt their work. Analysis of the farm work records can provide visualization of farming know-how or even help to identify inefficiencies. Such information is useful for improving product quality and reducing costs as well as work time. The proposed solution of combining an intelligent microphone and VoiceRex can be applied to other areas besides agriculture. It is ideal for use in any situation where workers need to input spoken information in a noisy environment. We are studying the application of this solution in factory situations. 3. Cloud-based pallet management system using 920-MHz bandWe have developed a pallet management system that uses the 920-MHz band. In this section, the features and management of the system are explained. 3.1 Overview and features of this technologyThis pallet management system [2, 3] must be able to manage an inventory of tens of thousands of pallets stored in a large depot where the floor could stretch over several hundred meters. It is also required to handle several hundred inbound and outbound pallets, brought in or out by trucks, in a matter of several minutes. In addition, it is desirable that wireless terminals (WTs) used by the system remain operational without replacing batteries during the lifetimes of the pallets, which is about 10 years. To meet these requirements, we have developed a high-capacity protocol technology for the 920-MHz band. The WT attached to each pallet manages two states: static and vibrating. The static state indicates that the pallet is stored in the depot. The vibrating state shows that the pallet is being conveyed by a truck or forklift. This state is recognized when the vibration sensor installed in the WT detects a vibration. The WT periodically transmits the state information, together with the WT ID (identification) and the temperature measured by the temperature sensor, using a beacon signal. The transmission intervals of the beacon signal are controlled according to the state of the WT. Transmission intervals are short in the vibrating state because it is necessary to detect this state instantly. Long transmission intervals are used in the static state so that many WTs can be handled and the batteries will last longer. The static state and the vibrating state use different frequencies in order to avoid interference between them. 3.2 Management of product location and stateThe pallet management system can be used not only to manage the locations of pallets but also to manage the products stacked on the pallets. One example of the latter is management of agricultural products. An overview of the application of the pallet management system to agriculture is shown in Fig. 5. A pallet is associated with the agricultural product stacked on it. For example, Pallet 1 is associated with spinach. This association is managed by the server in a cloud. The location and the state (information from the vibration sensor and the temperature sensor) of each farm product can be detected by receiving the beacon signal sent by the WT attached to the pallet on which the farm product is stacked. If a beacon signal from a WT is received by the base station installed inside the depot, the user can tell that the associated farm product is stored in the depot and can also ascertain the state of the stored product. If, however, a beacon signal is received by the base station installed in a truck, the user recognizes that the associated product is being conveyed by the truck and can also ascertain the state of the transporting product. Attaching the WTs to containers or other items used for transportation enables users to manage the locations and states of various agricultural products.

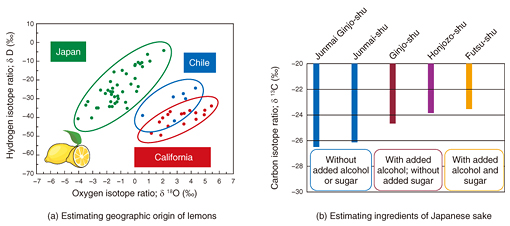

As a result, the locations and states of agricultural products in the distribution chain, whether being stored in a depot or being transported, can be managed without adding to the workloads of those who need to manage the products. 4. Preventing false food labeling with laser lightWe report here on the use of laser gas sensing technology to prevent false food labeling. 4.1 Overview and features of this technologyThe falsification of imported food as ‘made in Japan’ has been recognized as a social problem in recent years and has aroused the interest of consumers in food safety and authenticity of the geographic origin of food. The government is intensifying its efforts to protect regional brands of food products [4]. An effective way to prevent such falsification is to add scientific examination to the conventional document-based means of ascertaining authenticity in the supply chain of a food product. The geographic origin of food has been identified by analyzing the stable isotope ratios of hydrogen (H), oxygen (O), and carbon (C) contained in the food. The stable isotope ratio can be measured quickly and accurately by using laser gas sensing technology with highly sensitive semiconductor lasers developed by NTT. Hydrogen, oxygen, and carbon contained in the food are converted into gas such as vapor (H2O) and carbon dioxide (CO2) through either vaporization or burning. Since the gas molecules absorb the energy of light at a particular wavelength, which depends on the atoms of which the molecule is composed, the stable isotope ratios in the gas can be analyzed by the precise measurement of the absorption ratio while the laser light passes through the gas [5]. It is known that the stable isotope ratio of precipitation (H2O) is related to the geographic conditions. Most water molecules consist of two hydrogen atoms whose mass number is 1 and an oxygen atom whose mass number is 16. However, they also contain extremely small amounts of heavy water molecules that consist of an isotope of hydrogen whose mass number is 2 or an isotope of oxygen whose mass number is 18. The proportion of heavy water molecules in precipitation tends to be higher in hot regions, for example, near the equator, and lower in cold regions at higher latitudes. Since plants and animals consume the rainwater in the region where they have grown, the stable isotope ratios of hydrogen and oxygen in a plant or an animal are related to those in the rainwater. Therefore, the stable isotope ratio analysis of food products is helpful to estimate the geographic origin of food (Fig. 6(a)). The stable isotope ratio of carbon depends on the process of photosynthesis. This means that it is possible to obtain information about the plant species in addition to environmental information about where the plant was grown. The stable isotope ratio of carbon among the main ingredients of Japanese sake, wine, or honey (rice, grapes, or plants that produce honey) differs greatly from that of added sugar (sugar cane and corn). Therefore, carbon stable isotope ratio analysis will be useful to prevent false labeling or adulteration with sugar to sake or honey (Fig. 6(b)).

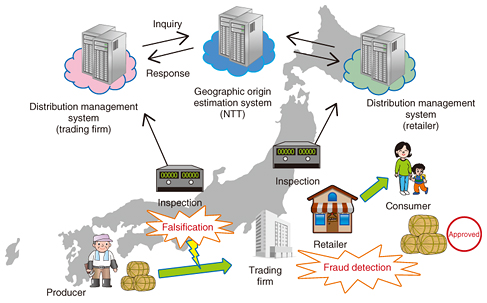

4.2 Preventing food falsification in supply chainThe laser gas sensing device is compact (about the size of a desktop computer) and easy to operate, and it can reduce the measurement time dramatically compared to mass spectrometry, which is well known as the most widely used method for stable isotope ratio analysis. These advantages enable supply chain screening. By incorporating scientific inspections using a laser gas sensing device to a supply chain system used by trading firms and retailers, it will be possible to achieve a more reliable management system to prevent false labeling and adulteration (Fig. 7).

5. Future plansIn addition to the items introduced in this article, NTT R&D has a number of other technologies that can be applied to agriculture. With a view to accelerating the utilization of these technologies to open up new agriculture-related business opportunities, we plan to aggressively pursue co-innovation with a wide variety of partners. References

|

|||||||||||