|

|||

|

|

|||

|

Short Reports Vol. 16, No. 9, pp. 44–46, Sept. 2018. https://doi.org/10.53829/ntr201809sr1 Completely Rewriting Industry’s Understanding of Transmitting High Quality Laser Processing Light over Long Distances1. IntroductionNTT and Mitsubishi Heavy Industries, Ltd. (MHI) entered into a cooperative agreement in April 2014 to undertake projects with the goal of creating new value for each other and their customers by applying NTT’s research and development results in the area of information and communication technology to MHI’s social infrastructure products in fields such as energy, the environment, and transportation, and to plant sites in Japan and other countries [1]. NTT and MHI have demonstrated kilowatt-class, high power single-mode laser transmission over several dozen to several hundred meters by harmonizing NTT’s photonic crystal fiber (PCF) technology and MHI’s high power laser processing technology. The maximum transmission distance of over-1-kW single-mode laser light is limited to around only 10 m at present. Our achievement therefore makes it possible to transmit high power single-mode laser light much longer distances, that is, up to several dozen times farther than before. Laser processing technology is being used in various social infrastructure products, including vehicles and airplanes, as an efficient method for cutting, hole forming, welding, and other processes, and its application field is expected to increase further. Our achievement enables us to transmit high power single-mode laser light for distances greater than was thought possible, while retaining the light’s quality, to yield high accuracy laser processing sources. Consequently, this will be a key technology for accelerating the expansion in the application areas of laser processing technology and for fostering further innovation in social infrastructure products. 2. Summary of achievementsIn this achievement, NTT and MHI overcame the limitations in transmission optical power and distance by employing PCF and achieved superior high power transmission performance and feasible optical fiber manufacturability simultaneously by proposing a novel cross-sectional hole arrangement. These key advances enable us to design a PCF with high power transmission potential four times higher than that of existing single-mode fiber for high power single-mode laser transmission. Moreover, NTT and MHI successfully demonstrated 10-kW transmission over 30 m and 1-kW transmission over 300 m using a high power single-mode laser light source and a fabricated PCF. This achievement expands the application area of high power single-mode laser processing and is expected to dramatically advance manufacturing technology in various social infrastructure industries. 3. Details of achievementsIn this section, the PCF is described in more detail, and the results of experiments we conducted are explained. 3.1 Reason for deployment of PCF (features of PCF)The optical fiber used to deliver the light from high power single-mode laser to arbitrary processing sites must offer high output power and excellent beam quality. However, the optical power and distance in an optical fiber are limited by optical nonlinearity. The maximum transmissible optical power and output beam quality of an optical fiber can be improved by various means, as follows:

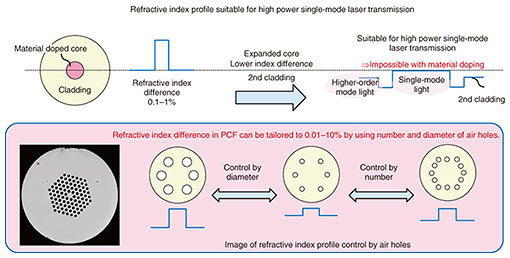

However, these requirements demand extremely precise refractive index control, on the order of 0.01%, which is impossible with conventional optical fiber as it has a material doped core. The PCF, on the other hand, confines the light to a region surrounded by an array of air holes. The effective refractive index of the air hole array can be set arbitrarily by altering the diameter d and number (alternatively, pitch Λ) of the air holes. Thus, the cross-sectional refractive index of a PCF can be designed precisely to the order of 0.01–10%. This superior control of the refractive index enables us to achieve single-mode transmission at arbitrary wavelengths. NTT has successfully developed a low loss PCF for realizing large capacity transmission at arbitrary wavelengths. Moreover, NTT created an optical fiber cord that can be used even if bent at 180 degrees without any optical signal degradation by combining the strong confinement effect of air holes with conventional optical fiber. As a result, NTT and MHI have succeeded in transmitting high power single-mode laser light to remote processing sites with no quality degradation by employing the superior refractive index control offered by the PCF (Fig. 1).

3.2 Novel quasi-uniform PCF and its optimizationAs mentioned above, the transmission properties of the PCF can be precisely controlled by setting the diameter d and pitch Λ of air holes. Further improvement is possible by combining multiple d and Λ values to design the cross-sectional air hole arrangement. However, the complex cross-sectional design severely degrades the manufacturability of optical fiber. To eliminate this problem, we developed for the first time a quasi-uniform PCF; it has a constant d, but Λ varies. This enables us to expand the effective core area while ensuring feasible levels of manufacturability. Moreover, we numerically clarified that by optimizing the values of d and Λ, the proposed quasi-uniform PCF can achieve 420-kW·m high power single-mode transmission. Power at this level is four times higher than that of existing optical fiber. 3.3 High power single-mode transmission experimentsA 30-m-long quasi-uniform PCF was fabricated based on the design guidelines. The output of a 10-kW single-mode laser light source was successfully transmitted over 30 m, and experiments confirmed its high power transmission potential of 270 kW·m. Similarly, a 1-kW single-mode laser light was transmitted over 300 m, which corresponds to the high power transmission potential of 300 kW·m. 4. Future prospectsThe achievements described here have enabled us to expand the transmission distance of high power single-mode laser light from several meters to several hundreds of meters. Such performance surpasses the limits currently deemed inevitable in the laser processing field and thus improves the effective use of high power single-mode laser sources. The application of single-mode lasers not only improves the cutting and hole-forming accuracy but also reduces processing time by using the laser energy more effectively. This achievement can be used to implement remote processing, remote welding, and thick plate cutting in the existing manufacturing processes of vehicles, airplanes, marine vessels, and other products. This achievement is expected to trigger rapid expansion in the application area of laser processing technology to an extremely wide variety of social infrastructure products, and to lead to greater innovations in manufacturing. Reference

For InquiriesPublic Relations, Planning Department, NTT Information Network Laboratory Group |

|||