|

|

|

|

|

|

Feature Articles: NTT Tsukuba Forum 2018 Workshop Lectures Vol. 17, No. 4, pp. 7–13, Apr. 2019. https://doi.org/10.53829/ntr201904fa1

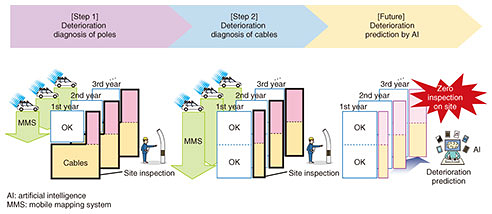

Research and Development of New Operating Techniques for Access Network InfrastructureAbstractThe team members of the Access Network Management Project at NTT Access Network Service Systems Laboratories have been engaged in research and development (R&D) related to the operation and management of access network infrastructure. This article reviews our recent R&D focused on innovating infrastructure maintenance and deployment. This includes techniques for carrying out facility inspections, condition sensing, and secure on-site work. It also introduces our vision for the future operation and management of access network infrastructure. This article is based on a lecture given during workshops at the Tsukuba Forum 2018 held in October 2018. Keywords: access network media, access network inspection and management, Tsukuba Forum 2018 1. IntroductionThe NTT Group has deployed a huge number of network facilities that require continued maintenance. However, the number of NTT workers is expected to decrease by about 40 percent by 2025. To continuously provide safe and secure telecommunication services, we need to progress beyond the conventional manual-handling operation and management work. In regard to on-site work, the number of serious accidents related to insufficient skill has increased in recent years, and it is difficult to prevent such accidents due to the retirement of skilled workers. Therefore, there is an urgent need for the implementation of an accident-free deployment scheme to overcome skill insufficiency. 2. Innovative inspectionIn this section, our research and development (R&D) of technology enabling efficient inspection of access network infrastructure is introduced. Our vision for inspection procedures of the future is remote and predictive inspection. The approach to realizing this vision has three steps, as shown in Fig. 1.

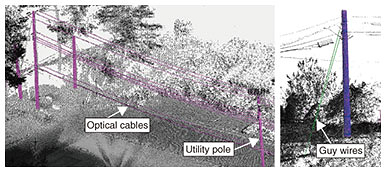

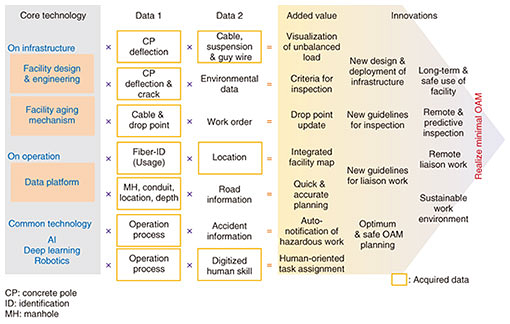

As the first step, we have designed an automatic diagnosis scheme for pole inspection. Pole inspection is the hardest aspect of infrastructure management since we have to thoroughly and manually check a large number of poles. With our diagnosis scheme, we plan to greatly reduce on-site work by categorizing poles into safe and unsafe groups and focusing inspection work on the unsafe poles. The second step is to extend the target of the diagnosis scheme to cables, guy wires, and suspension wires to further reduce the amount of on-site work. However, on-site inspection work must still be undertaken for the unsafe facilities even if we achieve the above two steps. To realize our future vision where on-site work is unnecessary, we plan to employ artificial intelligence (AI) technologies to estimate the aging condition of a facility and predict its lifetime. 2.1 Deterioration diagnosis of polesThe mobile mapping system (MMS) is a commercial technology that automatically captures outside objects as three-dimensional (3D) point cloud data while the inspector travels in a measuring vehicle and scans poles with a laser. We used the MMS to measure pole slopes and bends automatically by extracting each pole from the point cloud data. In addition, we also developed a Structure Deterioration Examination System, which incorporates an efficient data processing scheme to analyze a huge number of point cloud data. This system was put into practical use in 2018. 2.2 Deterioration diagnosis of cablesWe also developed MMS-based measurement for cables and guy wires in addition to poles, as shown in Fig. 2. The point clouds of cables and guy wires were difficult to capture when they were interrupted by obstacles such as tree branches. To make them measurable, we collaborated with NTT Media Intelligence Laboratories and utilized their unique interpolation technique for our system. However, the interpolation section for drop cables is difficult to define because their start and end points are unclear. Thus, further R&D is required if we are to capture it completely. If our system could capture aerial facilities including drop cables, it would help us to find unsafe facilities remotely by measuring their slackness and heights.

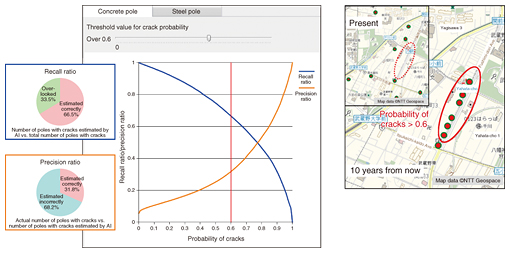

We also utilized the point cloud data as virtual reality (VR) space for remote inspection. In the VR space, which consists of 3D point cloud data, we can immediately reach the unsafe facilities, refer to the measurement results including pole slopes and cable heights, and check the on-site conditions with pictures. Moreover, facility alignment can be observed from a high vantage point by making the inspectors virtually giant. While our MMS-based measurement is helpful for remotely inspecting facilities as described above, it cannot be applied in areas inaccessible to vehicles. In conventional on-site work, pole bends are measured with a measurement instrument called a Baum, which is a total station that has a concentric circle reticle. However, this tool is specially designed for use with poles and cannot be employed for other kinds of facilities. We plan to employ a fixed laser scanner, which can easily capture point cloud data in areas inaccessible to vehicles, to achieve automatic inspection work in a similar manner to the MMS. 2.3 Deterioration prediction by AIHere, I explain our R&D aimed at facility aging prediction utilizing AI technology. Using AI that had learned pole data, we tried to predict the pole cracks that would occur in the next decade. However, the prediction accuracy was still imperfect. The AI estimation results are shown in Fig. 3 for poles predicted to have a greater than 60% crack probability. The recall and precision ratios were about 70% and 30%, respectively, which were at insufficient levels for practical use. We are going to further carry out R&D designed to improve prediction accuracy.

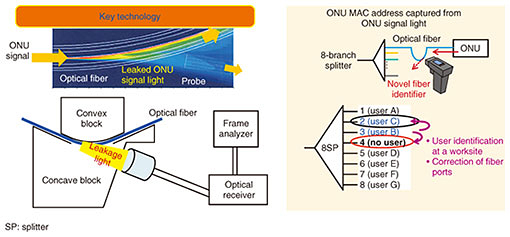

The various facility data acquired with our system can be combined to provide some added value. For example, the locations of the unsafe facilities can be visualized on a map combining pole slope and bend data, where the on-site conditions can be observed with pictures. By combining the map with unbalanced load data, we can simulate balanced facility alignment by moving the pole locations virtually on the map. The simulation results can also contribute to achieving more efficient operation by utilizing them when planning construction work. 3. Condition sensingIn this section, our sensing techniques for access network infrastructure are introduced. The first technique is optical fiber identification for the efficient operation of fiber-to-the-home (FTTH) connection/disconnection work. When we connect or disconnect branched fiber for FTTH at the splitter, the fiber and its associated FTTH user must be carefully confirmed to prevent accidents, since the fiber information specified by a service order is not always correct. Our technique enables us to easily identify an FTTH user on-site from the ONU MAC (optical network unit-media access control) address in the transmitted data frame by bending the branched fiber and detecting the light signal that leaks from that point, as shown in Fig. 4. This technique can be performed in-service by optimally designing the detection equipment. We believe that this technique will contribute to a reduction in back-orders by promoting efficient and secure on-site work.

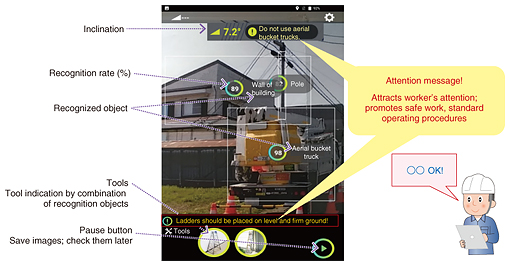

The second technique is manhole identification to allow us to check for flooded closures. The conventional method involved measuring the distance between an NTT building (central office) and a flooded closure using optical time-domain reflectometry (OTDR). However, the OTDR results did not always agree with the actual distance due to extra fiber length in the closure, since OTDR estimates the distance from the fiber length. Therefore, OTDR could not always identify the location of the flooded closure precisely, and we were sometimes forced to check additional manholes to confirm their condition. In contrast, our method identifies manholes by utilizing fiber vibration sensing technology. With this method, we cause the manhole to vibrate by hitting its cover with a hammer and then compare the detected vibration intensities for different manholes. This method can be efficiently carried out in combination with the conventional OTDR-based estimation technique. 4. Secure on-site workHere, I introduce our efforts to promote secure on-site work. The first development is the secure deployment of road-crossing cable. Road-crossing cable deployment is dangerous work, where there is the risk of serious accidents caused by cable entanglement with moving vehicles. To avoid such accidents, we developed automatic cable lifting equipment, which remotely lifts drop cable by reeling in a rope bound to the cable. The equipment is as heavy as a safety block, and is at a sufficient level for practical use. We plan to further reduce the weight to improve usability. The second development is a safety prechecking tool that utilizes augmented reality. This tool promotes secure work and assists fundamental actions by superimposing messages on the on-site view displayed on a tablet computer or smartphone, which automatically recognizes the on-site conditions, as shown in Fig. 5. In current deployment work, a voice-guided safety checking tool is already used; however, it is not always optimized for actual conditions. We believe that our newly developed tool will be helpful for promoting secure on-site work more effectively.

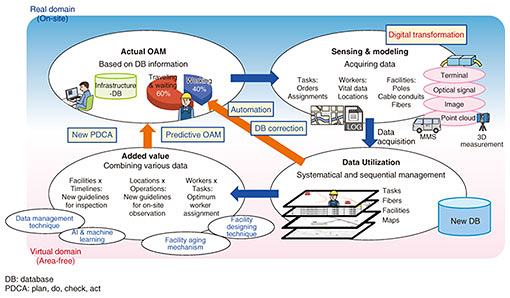

5. Future visionIn this section, I introduce our vision for the future operation and management (OAM) of access network infrastructure. Unlike network transmission and switching devices, most access network infrastructure, including cables and poles, cannot be remotely monitored. Thus, a large number of resources are needed to manage them. To address this situation, we plan to acquire and digitize various kinds of facility data with MMS and other condition sensing technologies. An overview of our vision and the roadmap for future OAM are respectively shown in Figs. 6 and 7. Condition sensing through daily operation work helps improve the integrity of the current database, leading to further automation of operation work. Moreover, the various types of acquired data create added value that changes the operation scheme when the data are combined. For example, unbalanced load conditions in facilities can be visualized by combining our unique know-how for designing constructions, pole slope and bend data, and facility configuration data. This approach leads to the realization of minimal maintenance work such as load balancing by readjusting the cable tension without replacing the facility itself, resulting in a reduction in the investment cost needed for facilities. The combining of various data also has the potential to establish a new standard that will enable minimal on-site inspection. We will continue promoting further R&D to achieve minimal OAM.

■Author profileTakeshi AraiExecutive Research Engineer, Access Network Management Project, NTT Access Network Service Systems Laboratories. He received a B.E. and M.E. in instrumentation engineering from Keio University, Kanagawa, in 1991 and 1993. He joined NTT in 1993. He is currently engaged in R&D focused on operating techniques for the optical access network. |

|