|

|||

|

|

|||

|

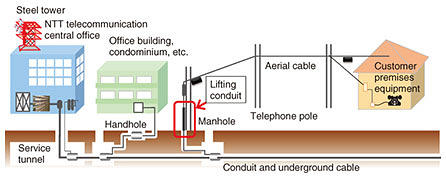

Practical Field Information about Telecommunication Technologies Vol. 18, No. 2, pp. 44–48, Feb. 2020. https://doi.org/10.53829/ntr202002pf1 A New Method for Repairing Steel Lifting ConduitsAbstractThis article introduces a simple and low-cost repair method applied to damaged lifting conduits and presents the results of its technical verification. This is the fifty-sixth article in a series on telecommunication technologies. Keywords: lifting conduit, corrosion, repair method 1. IntroductionThe telecommunication cables connecting a NTT telecommunication central office and customer premises run through underground facilities before being carried by overhead facilities to the customer premises. When a cable leaves an underground facility and is taken up to an overhead facility, it is housed in a steel pipe called a lifting conduit installed alongside a telephone pole (Fig. 1). The function of the lifting conduit is to protect the cable (Fig. 2). Since lifting conduits are exposed when coming into contact with the ground, they are typically treated with anti-corrosion materials such as zinc-plating and painting.

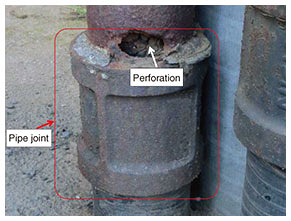

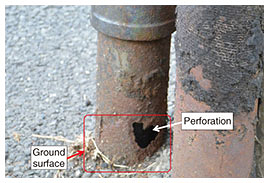

In the joint portion of the conduit (Fig. 3) and the portion close to the ground (Fig. 4), rainwater or damage due to external factors such as impact by vehicles will cause surface corrosion of those portions, and the surface corrosion will lead to the formation of holes (perforations). As the perforation progresses, the conduit may be further damaged, e.g., cracking. As a result, as well as the appearance of the conduit being deteriorated, the cable may become exposed outside the conduit and became further damaged by external factors such as impact by vehicles, which could be lead to telecommunication service interruption.

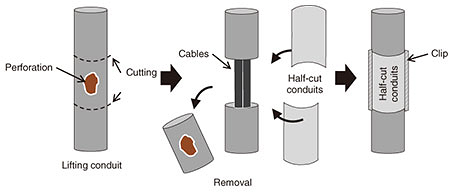

It is thus necessary to appropriately repair damaged lifting conduits. The repair method described in this article was originally developed by Yokohama Service Center of NTT EAST-Minamikanto Corporation, and the Technical Assistance and Support Center (TASC), NTT EAST, verified and validated on the basis of in-house standard method. The TASC conducted technical verification of this repair method (in terms of weather resistance, etc.) for damaged lifting conduits. This article introduces noteworthy features on this repair method and presents the results of its technical verification. 2. Current methods for repairing lifting conduitsWhen a lifting conduit is damaged by corrosion it is desirable to repair it on site, rather than to replace the whole of lifting conduit. The repair method is selected according to the size of the holes formed in the conduit and the degree of corrosion. Examples of conventional repair methods [1] are listed below. (1) Half-cut-conduit method The corroded lifting conduit is cut vertically using an exclusive tool to remove the corroded section, and two pieces of half-cut conduit are attached to the original conduit and fixed with several clips to cover the cables (Fig. 5).

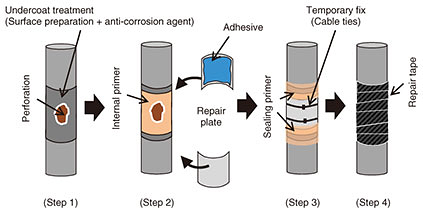

(2) Over-cleat method The existing lifting conduit does not need to be cut. First, the corroded section is removed and primed with resin, which is used to bond stainless-steel repair plates around that section. After that, resin intermediate coating, glass-cloth winding, a resin top coating, and anti-corrosion paint are coated. The most representative method for repairing lifting conduits is the half-cut-conduit method. This method has the advantage that even a conduit with large corrosion holes can be repaired; however, it is necessary to cut the conduit and remove parts of it. Accordingly, care must be taken to avoid accidentally damaging the cable during repair work. The over-cleat method, with which the steel lifting conduit is not cut, has two problems: (i) repair work takes a long time and (ii) repair work requires a specialist; thus, a damaged lifting conduit cannot be easily repaired. In consideration of these problems with such conventional methods, NTT EAST-Minamikanto developed a new method for easily repairing steel lifting conduits. 3. New method for repairing lifting conduitsThe new repair method mainly consists of four steps: (i) undercoat treatment, (ii) coating of an internal primer and attachment of repair plates, (iii) coating of a sealing primer, and (iv) wrapping with glass-fiber tape (Fig. 6).

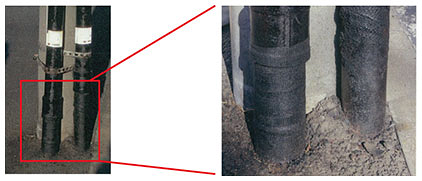

(1) Step 1: Undercoat treatment A metal brush or sandpaper is used to remove the rust around the areas where coatings have peeled off (hereafter referred to as repair area). An anti-corrosion agent is then coated by brush to the repair area and dried. (2) Step 2: Coating and curing of internal primer and attachment of repair plates A photo-curing resin (internal primer) is uniformly coated to the inside of the repair plates (within the repair area) and cured with natural or ultraviolet (UV) light. The internal primer prevents contact corrosion of a dissimilar metal between the lifting conduit (steel) and repair plates (stainless steel). Adhesive is then applied to the repair plates, which are then adhered to the repair area. (3) Step 3: Coating and curing of sealing primer A photo-curing resin (sealing primer) is applied evenly to the gaps between the conduit and the repair plates as well as to areas where the existing anti-corrosion agent peeled off. The repair area is then irradiated with natural or black light for curing. (4) Step 4: Wrapping with glass-fiber tape Glass-fiber tape (hereinafter, repair tape) is wound around the repair area while pulling it tight so that there is no looseness in the repair area or above and below the widths of the repair tape. By wrapping the repair tape in a manner called half-overlapped one-return lap, the overlapping tapes complement each other and prevent adhesion from decreasing. By straddling the boundary between the anti-corrosive area and area coated with sealing primer and by ensuring the repair tape completely covers that entire area, it is possible to prevent rusting on the portion without the applied sealing primer (tape end). The materials used for the repairs are commercial products and therefore easy to obtain. Moreover, the new method has the advantage that repair work can be easily completed in a short time (about two hours). Photographs of two steel lifting conduits after repair are shown in Fig. 7. The surfaces of the repair areas are covered with repair tape, and the required strength is assured by the repair plates fitted inside, and rusting is prevented by coating the primer.

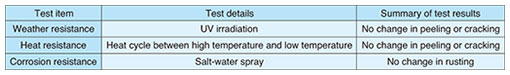

4. Verification of durability of lifting conduit repaired with new methodLifting conduits repaired with the new repair method would deteriorate under complexed conditions such as UV rays, wind and rain, temperature change, and sea salt. Accordingly, the TASC fabricated a test piece applied with the new method and verified its weather resistance, heat resistance, corrosion resistance, etc. in a simulation of an actual environment. The verification results were evaluated on the basis of standards defined in the specifications for repairing lifting conduits. The details of the verification test are listed in Table 1.

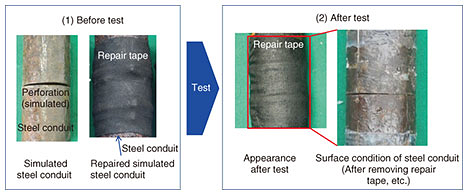

In the test, the new method was applied to repair a steel conduit with a simulated hole. According to the results of the test, NTT’s specifications, such as no visible change in rust state and no peeling of repair tape (Table 1), were satisfied. Photographs taken before and after the corrosion-resistance test are shown in Fig. 8.

The results presented in Table 1 indicate that the stipulated specifications were satisfied; thus, we confirmed that this new repair method can be employed for practical use. 5. Concluding remarksThe new repair method uses commercially available materials and do not require specialized technology for repair work, which can be completed in a short time (about two hours). Accordingly, in comparison with conventional methods, the new method enables lower repair costs while maintaining quality. In fiscal year 2019, NTT EAST will add this repair method to current repair methods for steel lifting conduits. The TASC will continue to promote technical cooperation activities aimed at solving on-site issues and contribute to improving the quality and reliability of telecommunication facilities. Reference

|

|||