|

|

|

|

|

|

Feature Articles: Smart Infrastructure Facility Management Vol. 19, No. 1, pp. 52–55, Jan. 2021. https://doi.org/10.53829/ntr202101fa8 Developing Smart Infrastructure Platform Based on the Smart Infra Business ConceptAbstractThis article introduces the Smart Infra Business Concept promoted by NTT Infrastructure Network Corporation (NTT InfraNet) for using information and communication technology to smartly implement maintenance and management work related to the telecommunication infrastructure facilities (such as utility poles and manholes) of the NTT Group. This concept is not limited to the NTT Group’s digital transformation but also forms the basis of the Smart Infra Platform to be implemented to solve problems faced by social-infrastructure companies. Three use cases for using the Smart Infra Platform are also introduced. Keywords: facility-management information, smart maintenance, Smart Infra Platform 1. Current status of the NTT Group’s telecommunication infrastructureAs mobile communication evolves to the fifth- and sixth-generation systems, the amount of data is expected to keep increasing. The traffic volume in 2030 is expected to be about 1000 times larger than that in 2010; thus, it will be necessary to increase the capacity of communication facilities in accordance with the increasing traffic volume. Accordingly, the demand for access networks connected to wireless base stations and core networks (relay networks) will also increase. Construction of the telecommunication infrastructure facilities that support the NTT Group’s telecommunication networks peaked from the 1960s to 1980s. About 20 years from now, about 85% of such facilities will be more than 50 years old. In short, facilities are aging. To address this aging issue, communications via the aging metal cables will be switched to via optical cables. Due to advances in optical-cable technology and optical-communication technology, the amount of data transmittable via the same conduit has increased enormously. Therefore, it is not necessary to install additional conduits; however, it is necessary to continue to use the existing conduits. There is also the issue of the aging of the working population. As the working-age population declines in Japan, the number of maintenance personnel will decrease sharply; thus, there is an urgent need to improve the efficiency of facility maintenance and establish maintenance methods that do not require advanced skills or expertise. NTT Infrastructure Network Corporation (NTT InfraNet) has been maintaining the telecommunication infrastructure facilities of the NTT Group using information and communication technology (ICT). For example, our smart maintenance business includes inspecting communication facilities by using a mobile mapping system (MMS) and developing and operating a geographic information system (GIS) based facility-management system called Triple I+P (Infrastructure, IT, Innovation Platform) linked with the map system GEOSPACE created by the NTT Group. Considering that the industry that operates other social infrastructure facilities is in the same situation as that in which the NTT Group is operating, we have launched the Smart Infra Business Concept to solve problems faced by social-infrastructure companies by implementing facility-management technology that uses ICT owned by NTT InfraNet, and are aiming to develop smart maintenance businesses for such infrastructure companies. 2. The Smart Infra Business Concept and Smart Infra Platform2.1 The Smart Infra Business ConceptThe issues related to facility maintenance involving social-infrastructure companies are listed below:

NTT InfraNet has been promoting the Smart Infra Business Concept to create a new business based on the key concept of sharing = (joint construction + existing facility utilization + openness) as a guideline for initiatives in the infrastructure-facilities field (Table 1).

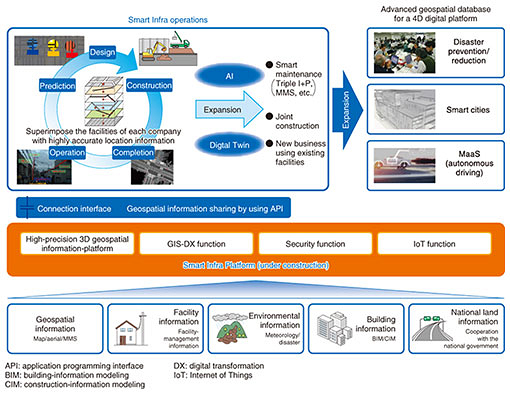

By sharing facility-management data possessed by each company, we aim to share infrastructure facilities with other companies by means such as joint housing of equipment and jointly carrying out operations that are commonly carried out by each company (such as construction, inspection, and on-site observation), which will contribute to reducing human resources and costs related to maintenance. It should be noted that the facility-management data mentioned here are not trade-secret information such as customer information or facility information but facility-location information and structural information (such as outward appearance) used for maintaining infrastructure facilities. 2.2 The Smart Infra PlatformDigital Twin Computing is a technology that reproduces the people and objects that make up the real world in cyberspace and combines them for conducting advanced simulations. Technology for reproducing information about the movements of humans and vehicles and their surrounding environment in real time in a digital-twin world is currently being researched and developed and expected to be introduced in the MaaS (mobility as a service) model, which includes autonomous driving. By constructing a static database on facilities of each infrastructure company in the digital-twin world and by planning and designing construction in cyberspace, the Smart Infra Platform enables infrastructure companies to determine the impact of the planned construction on the facilities of other companies in cyberspace, reflect that impact on actual construction work in the real world, and use this information for maintenance and equipment installation (Fig. 1).

The facility-management information of each company is currently managed on the basis of the map data of each company. If the original map data differ, the error between the map data and real wrold will also differ from company to company. As a result, when building a facility-management information database in a digital-twin world based on the facility-location information of each company, even if a facility is supposed to be in the same place in the real and digital-twin worlds, the facility locations in the two worlds will deviate by several centimeters to several meters. The Smart Infra Platform collects high-precision three-dimensional (3D) geospatial information as a core function. It then corrects the facility-location information of each company on the basis of the high-precision 3D geospatial information and builds a digital-twin world with that information. As a consequence, the error between the digital-twin world and the real world is reduced to a standard deviation of within a dozen centimeters. However, the location information of old underground facilities may be inaccurate, and if such information is managed with the position relative to the road edge, because the layout of roads is often changed through city planning implemented after the facility was buried underground, the initial position of the facility may be unclear. Through the Smart Infra Platform, when facility-location information is imported into the digital-twin world, the reliability information of the original data is also simultaneously imported; thus, when using the facility information in subsequent simulations, the risk associated with the simulation result can be determined. In addition, underground facilities cannot be viewed directly; therefore, a method for improving the reliability of unclear underground-facility location information is needed. To develop such a method, we are considering cooperating with NTT Access Network Service Systems Laboratories for their electromagnetic-wave search technology and AIREC Engineering for their underground-conduit-search technology. 2.3 Use cases concerning Smart Infra PlatformThe following three use cases are identified related to on-site observation of construction, which is one type of facility-management operation. (1) Automatic determination of presence or absence of a company’s underground facilities within the construction area When a construction contractor requests an operator of infrastructure facilities to carry out excavation work, the presence or absence of underground facilities of various companies in the construction area is determined. The operator confirms the results and reports the results to the construction contractor. The determination standard can be changed on the basis of the reliability of the location information of the underground facilities, and that determination can be fully automatic in areas with high reliability. (2) 3D display of underground facilities for consultations regarding construction Facilities buried in an underground space are displayed in 3D during consultations on construction work with a construction contractor. Currently, plan views, vertical profiles, and cross-sectional views are used during consultation. Displaying the underground space in 3D makes it possible to investigate high-risk points from various angles. In the future, this capability will lead to the implementation of remote construction consultations. (3) Augmented-reality display for supporting on-site observations On-site observers at a construction site confirm the impact on a company’s facilities by checking drawings of those that are buried underground. It is possible to improve the accuracy of predicting high-risk points by superimposing 3D information about the underground facilities on the site image and displaying the superimposition result as an augmented reality (AR) image. In the future, it will be possible to install remote cameras at the construction site and generate AR images that combine on-site remote images and 3D images of underground facilities, which may lead to implementation of remote observation. 3. Future directions of the Smart Infra PlatformThe Smart Infra Platform can contribute to smarter operations concerning digital transformation in each company; however, it can be even more effective by linking not only a company’s information but also linking to the facility-management data of other companies. By linking with the construction-related information of other companies, joint construction will be possible when different companies are constructing facilities in the same place, freeing different companies from having to excavate and re-pave the same area several times. As a result, it is possible to contribute to a better society by reducing construction costs and the impact of construction work on the general public (namely, road users) by shortening the construction period. By enabling further openness, the Smart Infra Platform can be used not only to share information between infrastructure companies but also provide danger-prediction information for autonomously driven vehicles. Sharing facility-failure information (i.e., failure area and failure factors) in the event of a large-scale natural disaster and prioritizing inspection areas of a company in consideration of the failure situation of other companies will make it possible to understand failure situations with higher accuracy and formulate an efficient recovery plan.

Authors (from left): Koichi Furukado, Manager, Smart Infra Promotion Department, NTT InfraNet; Yoichiro Takaki, Senior Manager, Smart Infra Promotion Department, NTT InfraNet; and Takashi Murakami, Manager, Smart Infra Promotion Department, NTT InfraNet |

|