|

|

|

|

|

|

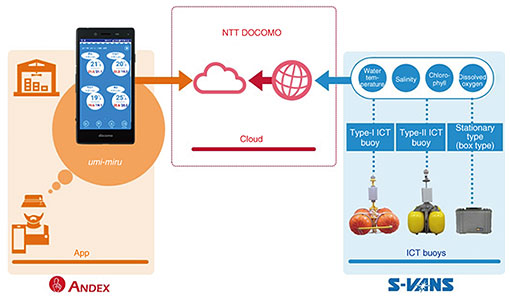

Feature Articles: Initiatives for Smart Agri—Making Japanese Agriculture a Growing Industry Vol. 19, No. 8, pp. 26–30, Aug. 2021. https://doi.org/10.53829/ntr202108fa4 “Fisheries +d”: NTT DOCOMO’s Solution Co-creation for the Fisheries IndustryAbstractWhile there is no end in sight to the decline and depletion of natural fish and shellfish, the global fish catch is on the rise due to population growth and other factors. The need to reliably nurture marine resources while protecting the diversity of the oceans from pollution is growing in urgency. Accordingly, expectations regarding improvement and commercialization of sustainable aquaculture technologies are increasing. NTT DOCOMO is focusing on the fisheries industry as the main area for industry creation underpinned by its medium-term strategy through 2020 called “Declaration beyond.” Under this strategy, we have developed marine-monitoring technology and aquaculture-management solutions that use ICT (information and communication technology) buoys and cloud computing, thus contributing to regional revitalization in collaboration with partner companies. This article introduces the initiatives of NTT DOCOMO in the fisheries industry. Keywords: fisheries, ICT, smart aquaculture 1. “Fisheries +d” initiatives began with support for post-disaster reconstructionIn April 2017, NTT DOCOMO announced its medium-term strategy, called “Declaration beyond,” and has been striving toward transforming itself from a mobile communications company to a “value co-creation company.” We believe that we can create new business and co-create new social value by combining the strengths of our partners in various fields, such as local governments, other companies, and research institutes, with NTT DOCOMO’s customer base, robust networks, information and communication technology (ICT), and other strengths. We refer to these initiatives with the suffix “+d” (plus d), in which d stands for NTT DOCOMO. “Fisheries +d” initiatives for solving problems in the fisheries industry has started with providing reconstruction support following the 2011 Great East Japan Earthquake. As part of that reconstruction support, we began exchanges with seaweed and oyster farmers in the city of Higashi-Matsushima in Miyagi Prefecture and thought that we want to not only support reconstruction but also create sustainable services that are useful for people engaged in the fisheries industry through NTT DOCOMO’s main business. A service that uses ICT buoys was developed to meet this goal. 2. ICT buoys for visualizing sea conditionsOne day, we heard from an oyster farmer in Higashi-Matsushima that “The sea conditions have changed since the earthquake, and our past experience and intuition are no longer valid.” Temperature and salinity (specific gravity) of the seawater at oyster farms are important factors in understanding sea conditions, and farmers used to measure them manually whenever they went to the oyster farms. To address this issue, we developed a service that uses ICT buoys equipped with sensors for measuring seawater temperature and salinity and communication modules installed at oyster farms. The sensor data—measured automatically every hour—are sent by the modules to the cloud, from which farmers can view the information via the app called “umi-miru” (“view the ocean” in English) installed on their smartphones. Together with our partners ANDEX and Sena and Vans Co., Ltd. (S-VANS), we began demonstration tests of this service in 2016 and launched a commercial service (Fig. 1) in October 2017.

Thanks to the introduction of ICT buoys, farmers have been able to continuously visualize sea conditions and support their experiences and intuition with data. Regarding edible-seaweed cultivation, we were able to confirm the effectiveness of ICT buoys for the “raising seedlings” process. Raising seedlings promotes the growth of seaweed through removing other seaweeds by exposing the seedlings (cells) of the seaweed attached to the seaweed net to the air. This is a key process that affects the taste, quality, and yield of seaweed. Seawater temperature and specific gravity had been measured at the seaweed farms before deciding on the work procedure for the day; however, thanks to the introduction of ICT buoys, past fluctuations in seawater temperature and specific gravity can be understood, so that work for the day can be determined on land. The farmers’ experience thus far has made it possible to interpret the data and predict the optimum timing and duration of drying out the seaweed, and “Thanks to ICT buoys, we can now imagine the appearance of seaweed cells on land,” said a seaweed farmer in Higashi-Matsushima. Information of ICT buoys spread through connections between farmers, and their introduction has progressed in major seaweed-producing areas such as Ariake Bay in southwestern Japan. In the 2017 Fisheries White Paper published by the Fisheries Agency, ICT buoys were mentioned as an example of ICT utilization in the aquaculture industry. As a result, the introduction of ICT buoys has expanded to aquaculture sites other than seaweed. For example, three ICT buoys were installed in Tsushima, Nagasaki Prefecture, for pearl-oyster farming in March 2018 (Photo 1). They were equipped with seawater temperature, chlorophyll concentration, and turbidity sensors. This case is the first in which chlorophyll concentration is constantly monitored throughout the year at a pearl cultivation site. “With the introduction of ICT buoys, we now know the seawater temperature and chlorophyll concentration every hour, so we can clean and treat Akoya pearl oysters (Japanese pearl oysters) according to the sea conditions. As a result, we can produce pearls of higher quality than ever before,” said Mr. Hidaka, the head of the Tsushima Pearl Farming Cooperative. Since 2019, ICT buoys have been added and eleven ICT buoys are currently in operation at pearl-oyster farms in Nagasaki Prefecture. Since 2019, we have also been receiving inquiries about ICT buoys from fish farming businesses concerning amberjack, red sea bream, and salmon. Regarding fish cultivation, sea conditions, namely, seawater temperature and dissolved-oxygen concentration, significantly affects the amount of feed intake and growth of cultured fish species. However, seawater temperature and dissolved-oxygen concentration are only measured during fish-feeding operations, and in many cases, feeding records are only managed analogically. When we visited aquaculture sites, we found that more than 90% of fish-farming companies are small and medium-sized, and fish-farming management is becoming more difficult due to sluggish fish prices and soaring feed prices. It is therefore difficult for fish farmers to invest in ICT, so we became acutely aware that ICT buoys alone cannot solve the problems facing fisheries sites.

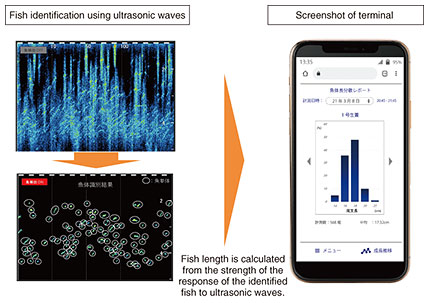

3. From visualizing sea conditions to solving problemsNTT DOCOMO entered the fisheries industry with the goal of visualizing sea conditions by using ICT buoys; however, we have shifted to a policy of listening to the voices from fishery sites and working with our partners to provide solutions to the problems that we hear. In May 2020, we entered into a business alliance with the SABAYA Group (SABAYA Co., Ltd., SABAR CO., LTD., and FISH BIOTECH Co., Ltd.). This business alliance aims to create a new market for safe, secure, and tasty farmed mackerel. In doing so, it hopes to encourage new entrants to the fisheries industry and contribute to revitalizing local communities and developing Japan’s fisheries industry. As part of the alliance’s efforts, a demonstration test to establish a new ICT-based mackerel farming model was launched in May 2020 at FISH BIOTECH’s mackerel farm in the town of Kushimoto, Wakayama Prefecture. NTT DOCOMO has developed and has been providing an “aquaculture management cloud,” a cloud environment that integrates the management of ICT buoys (stationary type) and mackerel farming. We have also conducted various ICT demonstration tests at the mackerel farming site in Kushimoto, including installation of cameras and other equipment and the use of underwater drones to check fish behavior and the presence or absence of leftover feed in fish ponds. Through these demonstration tests, we accumulated knowledge on how to deal with high seawater temperatures, which increases the mortality risk of mackerel as a result of infectious diseases and changes in the environment. We also confirmed the effectiveness of measuring fish length using ultrasonic underwater-visualization technology, improvements to the functions and user interface of the aquaculture management cloud, and the effectiveness of the “sea-condition simulation” service that we plan to launch. Fish length measurement and sea-condition simulation using ultrasonic underwater-visualization technology are introduced in the following subsections as examples of co-creation with a partner. 3.1 Measuring fish length using ultrasonic underwater-visualization technologyOn March 8, 2021, NTT DOCOMO and AquaFusion Inc. signed a business-alliance agreement to establish a new aquaculture-management model through development of an ICT service that uses ultrasonic underwater-visualization technology for automatically measuring fish length and weight. In the aquaculture industry, measurements of fish length and weight are key factors in efficient management of fish production. Until now, farmers had taken several farmed fish out of the fish tank with a scoop net and measured them one by one with a measuring instrument. However, physically handling the fish could kill them, and the growth of the fish extracted as samples varies, so it is difficult to accurately understand the growth process. Therefore, since October 2020, we have been verifying non-contact measurement of mackerel body length by using AquaFusion’s ultrasonic underwater-visualization technology during demonstration tests of cultured mackerel with the SABAYA Group. On March 11, 2021, we announced that we have succeeded in measuring the average length of mackerel swimming in a fish tank with high accuracy (Fig. 2). From now onwards, we will verify the estimation technique of fish weight from fish length using artificial intelligence (AI).

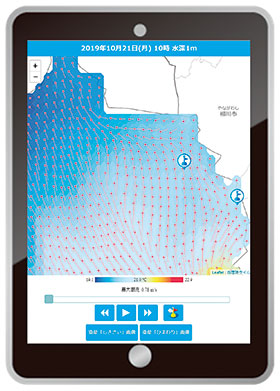

The ultrasonic underwater-visualization technology automatically analyzes the response of an object to ultrasonic waves transmitted at high frequency to identify a fish. This technology represents the world’s first use of CDMA (code division multiple access) for underwater ultrasonic measurement and enables ultrasonic transmissions of more than 40 times per second. Featuring resolution 100 times higher than conventional fish finders, it can identify individual fish even in densely populated environments such as fish ponds. The use of ultrasonic waves also makes it possible to measure fish even at night or when the sea is turbid, so the technology is independent of the measurement environment. Linking fish-length measurement service provided by AquaFusion with NTT DOCOMO’s aquaculture management cloud will make it possible to (i) accurately understand the growth process of fish as a function of the aquaculture-management cloud and (ii) provide ICT services for aquaculture with high added value, such as improving work efficiency and optimizing the amount of feed. 3.2 Sea-condition simulationSea-condition simulation is a service that is being tested in collaboration with Forecast Ocean Plus, Inc. and ANDEX (our partner in providing ICT buoys). Forecast Ocean Plus provides the information-consulting business for marine industries and public institutions and uses various prediction models resulting from the cutting-edge research of physical oceanography at the Japan Agency for Marine-Earth Science and Technology (JAMSTEC). NTT DOCOMO has been collaborating with Forecast Ocean Plus in developing a system that enables safe and efficient ship operation by equipping ships with terminals that can display tidal-current-forecast information provided by Forecast Ocean Plus. We began considering collaboration in the aquaculture industry in 2018 and developed the “umi-miru” smartphone app for sea-condition simulation with ANDEX around the summer of 2019, when the horizontal resolution of the sea-condition prediction model reached 1 km (Fig. 3). With this app, hourly forecast for the next three to five days of sea-condition information, i.e., seawater temperature, current speed, and current direction, predicted by Forecast Ocean Plus can be displayed in the form of animation. Since 2020, we have been verifying the use of the umi-miru sea-condition simulation at several aquaculture sites, including the above-mentioned mackerel farm in Kushimoto. After sufficient evaluation and verification, we plan to improve the app and commercialize it. In the bays where many aquaculture sites are located, it is difficult to predict sea conditions due to inflow from rivers, etc. By using sea-condition information, such as sea temperature, from ICT buoys provided by NTT DOCOMO as input information for Forecast Ocean Plus’s forecasting model, it is possible to improve the forecasting accuracy of sea conditions in bays.

4. Future developmentsThe Japanese fisheries industry is facing many challenges, such as a decreasing fish catches and an aging population of fishers and farmers. Working closely with our partners, NTT DOCOMO wants to contribute to revitalizing local communities and developing the Japanese fisheries industry by providing solutions to these challenges by using our experience and expertise in supporting the reconstruction from the 2011 Great East Japan Earthquake and in directly communicating with fishers and farmers.

Authors: (from left) Masako Nakashima, Assistant Manager, Kyushu Regional Office, NTT DOCOMO, INC.; Keiichi Yamamoto, Manager, ICT for Regional Revitalization Promotion Office, NTT DOCOMO, INC.; Yutaka Okabe, ICT for Regional Revitalization Promotion Office, NTT DOCOMO, INC.; and Yuko Yokoi, Assistant Manager, ICT for Regional Revitalization Promotion Office, NTT DOCOMO, INC. |

|