|

|

|

|

|

|

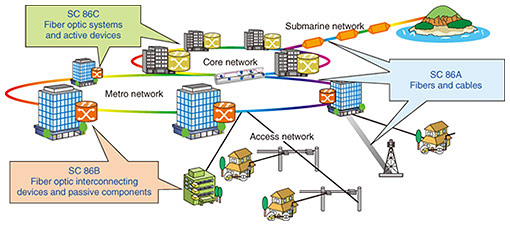

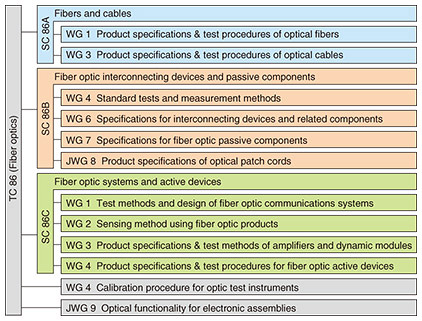

Global Standardization Activities Vol. 20, No. 10, pp. 82–86, Oct. 2022. https://doi.org/10.53829/ntr202210gls Standardization Activities for Optical Fiber and Cable Technology in International Electrotechnical CommissionAbstractThe International Electrotechnical Commission Technical Committee 86 (IEC TC 86) is an international standardization organization that prepares and decides on international standards in relation to products used for optical fiber telecommunication. In this article, we provide an overview of standardization activities, introduce topics discussed at the meetings in 2021 and 2022, and describe the Japanese standardization strategy in IEC TC 86. Keywords: IEC, optical fiber, international standard 1. IntroductionThe International Electrotechnical Commission (IEC) is a standardization organization that sets all of the required standards for electrical and electronics technologies. In IEC, Technical Committees (TCs), which are established for each technical field, hold detailed discussions on the content, publication, and revision of international standards, and TC 86 is in charge of specifications and test methods of optical products in optical communication systems. NTT is researching and developing technologies and requirements for optical communication systems, and international standards are closely related to equipment procurement and interconnection. Therefore, NTT is actively participating in IEC TC 86 standardization activities making proposals for international standardization, and involved in discussion of documents to guarantee the quality and interoperability of telecommunication networks and product specifications used in Japan. The International Telecommunication Union - Telecommunication Standardization Sector (ITU-T) Study Group (SG) 15 is also discussing international standardization for optical fibers and cables from the viewpoint of requirements for public communication network systems, and we are actively participating in it. In IEC, standardization is mainly conducted from the viewpoint of consistency between procurement specifications for optical products and international standards, and in ITU-T, standardization is being discussed from the viewpoint of securing interoperability of communication systems and requirements. Standardization activities in IEC and ITU-T are being conducted in close cooperation with each other. In IEC, TC 86 is in charge of fiber optics (optical fiber) technology, and its main purpose is to establish standards such as optical, environmental, and mechanical requirements of fiber optics products for optical communication systems, which are optical modules and devices used with optical fiber cables, connectors, and communication equipment. The technical fields of TC 86 are shown in Fig. 1, and the organizational structure of TC 86 is shown in Fig. 2. TC 86 has three Subcommittee (SCs) to make decisions in each technical field. SC 86A is in charge of optical fiber cables, SC 86B is in charge of optical connecting and passive devices, and SC 86C is in charge of optical subsystems and active devices. It also has 12 Working Groups (WGs) to discuss specific standards documents. Each WG proposes new or revised standards for the technical field it is in charge of and prepares documents, which are then issued and reviewed by each SC. This article describes recent trends in optical fiber and cable standards being discussed in IEC TC 86.

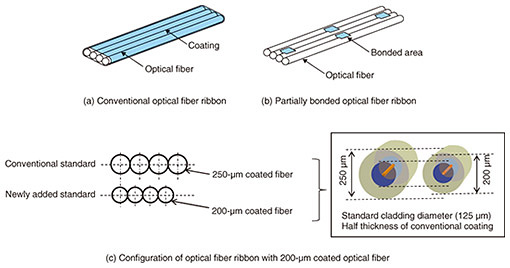

2. Recent trend in standardization for optical fibers and cablesIn the field of fiber optics for IEC TC 86, discussions on the standardization of optical cables and connecting devices for access systems have been active, especially against the background of the rapid increase in demand for optical fiber cables in datacenters and the rapid spread of FTTH (fiber to the home) in Europe and emerging countries. At SC 86A, which handles optical fiber cable standards, revisions are being made to optical fiber and optical fiber ribbon standards in line with the increasing number and high density of optical cables, and proposals and discussions are being made on various testing methods for optical cables in consideration of the usage environment in each country. The standardization of a partially bonded optical fiber ribbon, which was developed and used for ultra-high density optical cables in Japan, has been discussed. Figure 3 shows the configuration of an optical fiber ribbon. A partially bonded optical fiber ribbon can be discretely bonded in the longitudinal direction to improve flexibility, such as being able to roll up or bend in any direction, and can be mass spliced. By using the partially bonded optical fiber ribbon, the optical fiber assembled density in the optical cable can be dramatically increased, and it is commercially used for optical fiber networks in Japan. In IEC, the standard document was newly established as a product standard of optical fiber ribbon (IEC 60794-1-31). It has recently been applied to ultra-high fiber-count optical cables for inter/intra datacenter networks. In ultra-high fiber-count optical cables, it is effective in reducing the coating diameter of the optical fiber ribbon to make it smaller and denser. In addition to the standard coating diameter of 250 μm, an alternative coating diameter of 200 μm has been standardized. By applying this to optical fiber ribbon, it is possible to reduce the diameter, increase the density, and improve connection efficiency. In view of the situation in which connection compatibility can be ensured by the progress of fusion-splicing technology corresponding to 200-μm coating, as shown in Fig. 3(c), the standard document was published as a product standard of optical fiber ribbon applying 200-μm coated optical fiber. For submarine optical fiber cables, it is necessary to increase the number of optical fibers as communication demand increases. We are also deliberating the application of 200-μm coating, which is an alternative coating diameter, to cut-off shifted fiber (IEC 60793-2-50: B-654. A, B, and C) used for submarine applications.

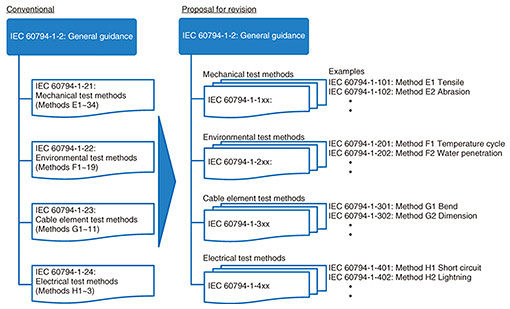

The standards of test methods for optical fiber cables are indispensable for proper characterization of optical fiber cables. Figure 4 shows the numbering system of such test methods and the proposal for revision. A wide variety of test-method standards are divided into separate volumes to ensure timely maintenance of each standard. Japan proposed a test method for evaluating the freezing resistance of optical fiber cables considering their installation in cold regions on the basis of NTT’s knowledge, and published it as a freezing test method (IEC 60794-1-215: Method E15C). Among the cable element test methods, Japanese experts are revising the document of the test methods for ribbon dimensions and geometry (IEC 60794-1-302: Method G2, IEC 60794-1-303: Method G3) and the test method for ribbon tear (separability) (IEC 60794-1-305: Method G5), which are closely related to the product standards for optical fiber ribbon, and deliberations are underway to make them appropriate test-method standards.

In the research and development (R&D) process, NTT conducts evaluation using these test methods to feedback to optical cable design and compatibility with the usage environment, and examines performance and reliability evaluation in practical application development of new products and expansion of application of developed products. Therefore, we are promoting the globalization of technologies developed by NTT and Japan through standardization activities in conjunction with R&D activities. 3. Further activitiesJapan has aggressively promoted the domestic deployment of optical-fiber-cable technology, and has a strong presence as one of the major countries in IEC TC 86. On the basis of our extensive experience and knowledge in the introduction and operation of optical fiber and cable technologies, we will contribute to the development of international standards that contribute to the development of optical communication networks by closely cooperating with ITU-T, which is also involved in international standardization. We will also promote the establishment of next-generation optical fiber and cable technologies, which will be indispensable for IOWN (the Innovative Optical and Wireless Network), through both R&D and standardization activities. |

|