|

|||||

|

|

|||||

|

Special Feature on Technical Solutions to Real-world Problems Vol. 5, No. 8, pp. 8–10, Aug. 2007. https://doi.org/10.53829/ntr200708sf2 A More Efficient Method of Inspecting Utility Pole Damage Caused by Major EarthquakesAbstractEarthquakes such as the Niigata Prefecture Chuetsu earthquake are expected to produce severe damage to communication facilities. In addition to the obvious need for early restoration of service immediately after the disaster, an important task in reconstruction is to ensure the reliability and safety of locations where the damage may not be obvious. This article describes an efficient maintenance inspection method devised as a result of investigating the damage to utility poles that occurred in the Chuetsu earthquake.

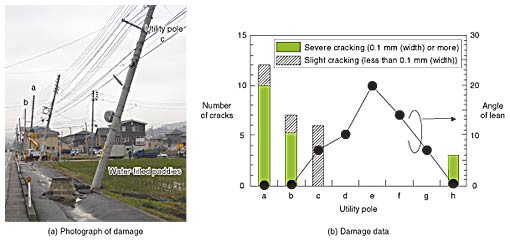

1. Damage to utility poles in the Chuetsu earthquakeThe Niigata Prefecture Chuetsu earthquake, which occurred on October 23, 2004, registered a maximum seismic intensity of 6.9 on the Richter scale. It caused serious loss of life and many injuries and severe damage to homes, buildings, roads, and infrastructure facilities such as gas, water, and electricity supplies. Damage to communication facilities was also severe [1]. A total of 3401 utility poles supporting communication cables were toppled, broken, or left leaning. That is about the same number of poles as damaged in the Hanshin-Awaji earthquake, which registered 7.2 on the Richter scale. Most of the damage in Niigata occurred because the poles had been installed on weak ground, so they were damaged by ground movement (Fig. 1).

2. Restoration of damaged utility polesThe repair of collapsed, broken, or leaning utility poles, an essential first measure in the restoration of communication and maintenance of safety, can be accomplished through the efforts of maintenance technicians. There are, however, facilities that appear normal at a glance, but which have reduced reliability as a result of cracking or bending. Post-earthquake inspections for safe operation of communication facilities require a huge amount of labor and time. Therefore, how to efficiently identify and inspect defects in a huge number of facilities is a problem that needs to be solved. We identified and categorized the damage for each type of installation environment and each type of utility pole. 2.1 Installation environmentsWe analyzed the circumstances of utility pole damage, broadly dividing installation locations into rural and urban areas. (1) Rural areasToppled and leaning utility poles are most often seen in areas where the installation is on weak ground or adjacent to weak ground. In particular, in places where utility poles are installed beside roads and anchored in hard asphalt adjacent to water-filled paddies, the swaying of the pole tops during an earthquake tends to cause leaning toward the soft-ground side (Fig. 2(a)). In such damage areas, a utility pole that leans over more than the others (utility pole e) pulls down on the adjacent poles (a–h) (Fig. 2(b)) to produce a chain-like effect that results in a series of leaning utility poles. In such circumstances, cracking or other such damage is not seen in the pole that leans the most, but such other damage is found in the surrounding poles that lean only slightly. Therefore, it is necessary to inspect and repair the surrounding poles as well as to repair the poles with the most obvious damage.

(2) Urban areasIn residential districts and other such areas where utility poles are anchored in asphalt or other hard material that completely surrounds them, the leaning phenomenon seen in rural areas is seldom observed. Most of the damaged utility poles have horizontal cracking near the base (Fig. 3). This cracking is believed to result from the large moment created by the swaying pole top due to seismic movement and the firmly anchored base. For utility poles installed in urban areas, it is therefore important to focus inspection on the part of the pole near the base, where damage is most likely to occur.

2.2 Type of utility poleThe tendency of a utility pole to sway depends on the weight and length of the pole itself and on other constraints such as the cables it supports. Therefore, we analyzed the degree of damage according to the type of utility pole. We found that the order of damage severity was as follows. • Concrete pole > steel pole • Combined utility pole*1 > dedicated pole*2 • Heavy suspended weight > no heavy suspended weight • End pole*3 > pole at a curve*4 > intermediate pole*5 Most of the damage to concrete poles was attributed to their high weight compared with steel poles. Looking at the details of the damage to concrete poles, we see that combined utility poles, which are long and heavy, had the highest rate of damage. In particular, combined utility poles that bore heavy weights such as transformers were the most frequently damaged. Furthermore, the damage also varied with the installation location of the utility pole. Because the suspended cables exerted asymmetric tension on the poles during seismic motion, the damage was greater for end poles followed by poles located at curves followed by intermediate poles. Based on a statistical analysis of these damage circumstances, we established an inspection priority according to the installation environment and type of utility pole. This raised the efficiency of the post-disaster inspection after the Chuetsu earthquake. 3. ConclusionWhen large-scale disasters such as the Niigata Prefecture Chuetsu earthquake occur, an important task in addition to the immediate work of restoring communications and ensuring safety after a disaster is to ensure the reliability of facilities in which damage may not be obvious. Ensuring the reliability of a huge number of facilities requires a lot of labor and time, but we have increased the efficiency of inspection work by systematizing the damage characteristics and establishing priorities. Reference

|

|||||