|

|||||||||||||||||||

|

|

|||||||||||||||||||

|

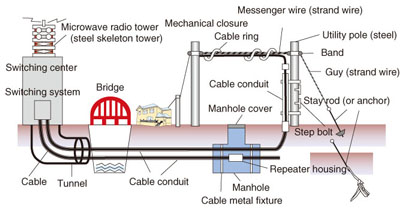

Feature Articles: Environmental and Energy Technologies for ICT Society Vol. 11, No. 1, pp. 23–27, Jan. 2013. https://doi.org/10.53829/ntr201301fa4 Increasing the Lifetime and Reliability of Telecommunication Plant MaterialsAbstractWe are researching and developing techniques to strengthen the reliability and environmental adaptation of telecommunication facilities in order to increase their lifetime. This article introduces examples of techniques to determine the degradation of coatings on telecommunication steel towers. An application to lightning damage prediction is also introduced as a risk-based facility maintenance strategy to evaluate the need for maintenance depending on the degree of risk. 1. Overview of telecommunication facilitiesAn enormous quantity of telecommunication plant materials is required to provide information and communications technology (ICT) services to communities. An example of some of the materials composing the outdoor infrastructure in the telecommunication field is shown in Fig. 1. NTT owns around 700,000 km of optical fiber cable, more than 1,100,000 km of long metal cable, approximately 12,000,000 telephone poles, and nearly 620,000 km of long cable conduits throughout Japan. Consequently, it is crucial to reduce the impact of these materials on the environment and to increase maintenance efficiency [1], [2]. We have investigated this issue focusing on the areas of materials science and a risk management system. In this article, we describe examples of techniques to determine the degradation of coatings on steel towers used for wireless telecommunications, and we introduce a risk-based facility maintenance application to predict lightning damage.

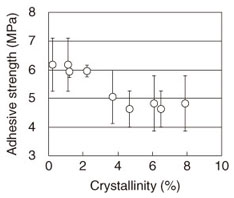

2. Technique to determine degradation of coatingsSteel towers and cable conduits under bridges are examples of outdoor equipment that are protected by organic coatings [3]. Steel towers have been installed at various NTT locations, and the maintenance of these huge structures includes periodical repainting. 2.1 Objective of degradation determinationVisual observation and adhesion testing are normally performed before NTT's steel towers are repainted. A practical cross-cut test (JIS K 5600-6-6) is used to evaluate adhesion. This involves cutting a section of the coating film into nine squares, placing adhesive tape over them, and then peeling off the tape. The number of remaining squares corresponds to the adhesion force. This is a simple evaluation method, although it is not very precise for detecting the onset of degradation. If the degradation goes undetected, corrosion will proceed, and this often results in the need to replace steel parts, which increases the maintenance cost. Therefore, we are developing new techniques to evaluate degradation. 2.2 Evaluation of film performance and material propertiesWe have introduced various coatings at NTT such as solvent-type coatings that are applied to steel towers and cable conduits used on bridges as well as powder coatings that are coated on steel telephone poles. It is possible to efficiently determine the film degradation by clarifying the relationship between film performance, that is, the film's adhesive strength and impact resistance, and the material properties. We have focused on the material properties, which are measurable and useful for determining the appropriate time to repaint and replace components. The relationship between the adhesive strength and crystallinity, one of the material properties [4], is shown in Fig. 2 for powder coatings. The crystallinity is the ratio of crystalline parts in a crystalline and non-crystalline mixture of polymer material. Polyester powder is a crystalline polymer, so the film performance varies depending on the degree of crystallinity. Good performance, which is higher adhesive strength here, was obtained with up to 3% crystallinity, as shown in Fig. 2.

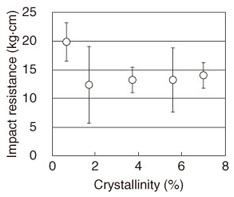

The relationship between the impact resistance and crystallinity [4] is shown in Fig. 3. As with adhesive strength, it is observed that higher impact resistance is obtained in the lower crystallinity region.

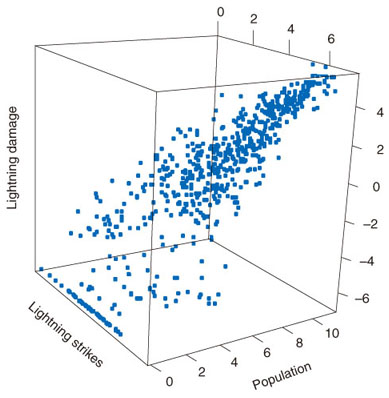

We were able to clarify practical film performance by understanding one of the basic material properties (crystallinity in this case). 2.3 Study of new material indicatorWe are developing new criteria to determine coating degradation and are focusing on viscoelasticity to quantify the degree of degradation of solvent-type anti-corrosion organic coating films. Viscoelasticity, as the name suggests, is the combination of viscous and elastic properties. It is generally known that most of the energy necessary to peel a film is consumed by deformation of the bulk material, and thus, the adhesive performance strongly depends on the viscoelasticity. Also, we previously reported that the viscoelasticity of solvent-type anticorrosion organic coating film varies depending on the degradation [5]. Thus, we believe that it is possible to precisely evaluate the degree of degradation by measuring viscoelasticity as the material property of the coating film. Furthermore, because this measurement is very sensitive to even a small variation of the property and because the measurement distribution is small, this technique is expected to indicate the onset of degradation. 3. Risk-based maintenanceRisk-based maintenance is a new methodology for maintaining infrastructure that involves assessing the risk for each component of the infrastructure and preparing an appropriate maintenance plan for each component on the basis of the risk assessment. This method makes it possible to balance the need to control maintenance costs with the requirement to ensure the reliability of the infrastructure. This method was developed with the intended use of maintaining chemical plants in western countries and is also being applied in chemical plants in Japan [6]. Telecommunication industries have not yet applied this method. The risk for a component is determined by the expected likelihood and consequences of a specific failure of the component. One of the first research tasks is to establish a method of estimating the likelihood and consequences using some particular data, such as information on facility features, inspection results, and weather information. Here, we introduce a method of estimating the risk of lightning damage. 3.1 Aim of method to evaluate risk of lightning damageFor many years, damage to telecommunication infrastructure caused by lightning surges has been a serious issue [7]. The cost associated with such damage has been increasing year on year as low-voltage LSIs (large-scale integrated circuits) and electrical devices connected to the network become more prevalent in the ever-expanding information technology (IT) society. Furthermore, our study of long-term trends in the number of annual days with lightning [8] indicates that lightning damage will become more serious because of the increased occurrence of lightning in Japan in conjunction with future global warming. Although lightning damage can be reduced by introducing lightning protection countermeasures, it is difficult to introduce countermeasures uniformly throughout the country because of the high cost. An advanced method is needed to classify areas by the cost-effectiveness of introducing countermeasures. We have been researching a method to evaluate the risk of lightning damage; it involves estimating the potential number of equipment failures and the subsequent economic loss. The estimation of the potential number of equipment failures corresponds to likelihood estimation in the risk-based maintenance, and the economic loss estimation corresponds to the consequence estimation. 3.2 Model for estimating degree of lightning damageWe analyzed the relationship between the number of equipment failures, the number of lightning strikes, i.e., the cause of the damage, and the amount of equipment, i.e., the location of the damage. A scatter plot graph of the logarithmic values of these three variables, where the resident population is substituted for the amount of equipment, is shown in Fig. 4. As this graph indicates, the number of equipment failures is proportional to both the number of lightning strikes and the resident population. Thus, we defined the lightning damage estimation model [9] as: 1og(Y)=log(a)+ b11og(L)+b21og(P). Here, Y is the number of equipment failures; L is the number of lightning strikes; P is the resident population; and a, b1, and b2 are coefficients of regression. We conducted a case study of three prefectures in Japan to validate the accuracy of the model using past data, and we confirmed that the correlation coefficient between the values estimated using our estimation model and the actual values was more than 0.8. These correlations can be considered statistically significant.

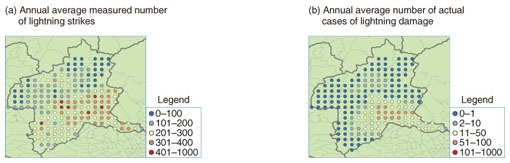

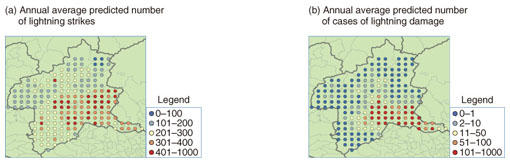

3.3 Prediction of future lightning damage and equipment failuresThe potential number of equipment failures can be estimated using the estimation model from the predicted number of lightning strikes [8] and population in the future. The average numbers of lightning strikes and equipment failures between 2006 and 2010 in Gunma prefecture, where the density of lightning strikes is among the highest in Japan, are shown in Fig. 5. The average predicted numbers of lightning strikes and equipment failures between 2026 and 2030 are shown in Fig. 6. The predicted results show that the number of equipment failures in the late 2020s will increase owing to the remarkable increase in the number of subscribers of optical fiber broad- band services and the increase in the number of lightning strikes.

3.4 Identification of high-priority areas for countermeasuresWe are using the results of our study to analyze the potential economic loss and the cost-benefit of implementing lightning countermeasures in nearly every region of Japan. Our method makes it possible to identify the areas where countermeasures should be implemented first and is thus expected to be useful to ensure the reliability of telecommunications services and to optimize maintenance costs by reducing lightning damage and maintenance work. 4. Future prospectsNTT will continue to develop techniques to assess degradation by focusing on coating properties and risk-based maintenance and will also continue working to reduce both environmental load and maintenance costs in the future. References

|

|||||||||||||||||||