|

|||||||

|

|

|||||||

|

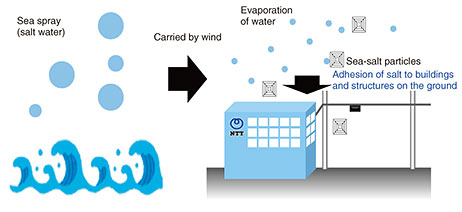

Practical Field Information about Telecommunication Technologies Vol. 20, No. 6, pp. 52–56, June 2022. https://doi.org/10.53829/ntr202206pf1 Salt Damage in RT-BOXes: Investigation and Countermeasures of Salt-damage EnvironmentsAbstractThis article provides an overview of salt-damage maps, describes a case study of salt damage in remote-terminal boxes (RT-BOXes) installed in coastal regions, and introduces methods of implementing environmental investigations and countermeasures against salt damage in RT-BOXes. This is the seventieth article in a series on telecommunication technologies. Keywords: salt damage, RT-BOX, salt-resistant filter 1. IntroductionNTT’s telecommunication facilities are installed in various natural environments throughout Japan. The materials that constitute these facilities, such as metals and plastics, deteriorate due to ultraviolet rays and other effects of the surrounding environment. As shown in Fig. 1, salt damage, one of the causes of such deterioration, is a phenomenon by which strong winds blow sea-salt particles (salt) onto metal-containing equipment, where they adhere and accelerate corrosion. Sea-salt particles blowing from sea spray fall to the ground in coastal regions owing to the limited distance they can travel; consequently, the effects of salt damage are more pronounced in facilities closer to the coast, which suffer premature deterioration.

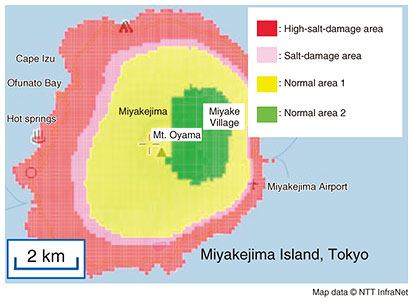

In response to requests from the field, the Technical Assistance and Support Center (TASC), NTT EAST, has been investigating the effects of salt damage to outdoor facilities and indoor equipment. At TASC, we have also devised ways to protect telecommunication facilities from salt damage by using salt-damage maps [1] and creating new inspection methods of determining the deterioration status of remote-terminal boxes (RT-BOXes) [2]. This article provides an overview of salt-damage maps, describes a case study of salt damage in RT-BOXes installed in coastal regions, and introduces methods of implementing environmental investigations and countermeasures against salt damage in RT-BOXes. 2. Salt-damage mapsThe salt-damage maps were created by NTT’s former Energy and Environment Systems Laboratories and the underlining technology was provided to NTT EAST in 2011. In 2018, TASC improved the maps by refining them with the latest weather data. As shown in Fig. 2, these maps display the corrosion rate of zinc with colors at any given point in Japan in a manner that makes it easy to determine the degree of salt damage by looking at differences in colors.

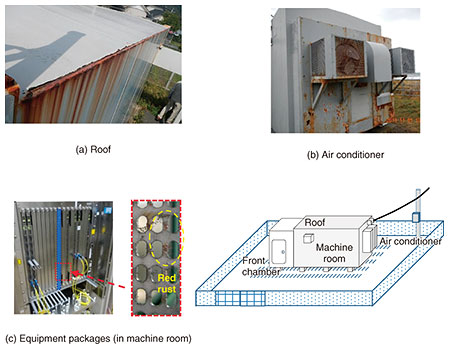

Hardware and other fixtures used in telecommunication facilities are galvanized on the surface (plated) to prevent corrosion of steel plates. Since the corrosion rate of zinc represents the rate at which this plating wears off, a high corrosion rate of zinc results in early loss of the zinc plating and direct exposure of the underlying steel plates to the environment. As a result, corrosion of the steel plates progresses at an accelerated rate, causing thinning of the plates that leads to problems in terms of strength and other safety aspects of the facility. Under such circumstances, a salt-damage map can be used to determine where to implement measures to deter early deterioration of facilities. Such measures include applying a heavy-duty anti-corrosion coating (with higher salt-damage resistance) to outdoor facilities in areas with severe salt damage. For indoor facilities, salt must be prevented from entering the facilities. The following section introduces an example of such a salt-resistance measure used for RT-BOXes. 3. Investigation of the salt-damage environment of RT-BOXes and related countermeasures3.1 Examples of outdoor and indoor corrosion in an RT-BOXThe occurrence of red rust on the exterior surface and interior of an RT-BOX installed in a coastal region is shown in Fig. 3. Outside the RT-BOX, rust occurs at the edges of structures where the paint tends to thin out and in areas where the structure is complex and moisture tends to accumulate. An example of such an area is where the outdoor unit of an air conditioner is installed.

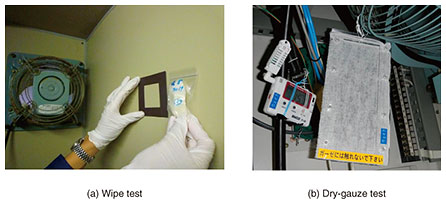

Indoors, rusting was observed inside the communication-equipment packages and on bolts inside the machine room, suggesting that salt was somehow entering the room. 3.2 Method of investigating the salt-damage environmentWhether the environment in which the telecommunication facility is located is significantly affected by salt damage can be evaluated by directly measuring the amount of salt present in the environment using the measurement methods. These measurements can also be taken indoors to determine if salt is entering the facility. The two measurement methods used for the interior of an RT-BOX are described as follows. Method I: Measuring the amount of adhered salt by conducting a wipe test (Fig. 4(a)). This method is used to measure the amount of salt remaining inside an RT-BOX. The surface of areas presumed to be less affected by access from workers thus more prone to salt accumulation, such as under equipment racks, is wiped with a non-woven cloth containing ion-exchange water to collect deposits. The amount of chloride ions (Cl–) contained in the deposits is measured using ion chromatography then converted into sodium chloride (NaCl) to determine the amount of adhered salt. Method II: Measuring the amount of airborne salt by conducting a dry-gauze test (Fig. 4(b)). This method is used to measure the amount of airborne salt that infiltrates an RT-BOX from outdoors. In accordance with JIS Z2382 (the Japanese industrial standard for measuring environmental-pollution factors to evaluate the corrosivity of atmospheres), a dry-gauze plate (i.e., a plastic plate with a dry gauze attached) is used to collect airborne salt. The plate is exposed to the atmosphere inside the RT-BOX, and salt suspended in the air adheres to the gauze. Specifically, several dry-gauze plates are placed on open-air inflow points inside the RT-BOX (such as near ventilation fans), and the dry gauzes are retrieved after approximately 30 days to collect the airborne salt. The amount of airborne salt is then measured using ion chromatography in the same manner as with Method I.

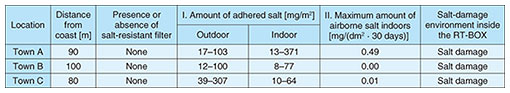

3.3 Investigation of salt-damage environment in RT-BOXes in coastal regionsThe results of the investigation of the amount of adhered and airborne salt in RT-BOXes in coastal regions are listed in Table 1.

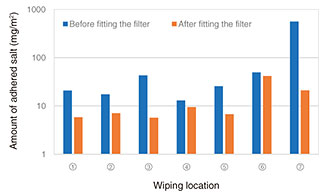

The maximum amount of adhered salt measured at ten locations inside an RT-BOX exceeded the standard for salt-affected areas (i.e., 50 mg/m2) in all RT-BOXes [3]. The amount of airborne salt measured at four indoor locations was particularly high in the RT-BOX in town A. These results confirm that for all RT-BOXes, salt infiltration into an RT-BOX occurs due to the coastal location of such facilities. 3.4 Countermeasures against salt infiltration by using salt-resistant filtersThe salt detected inside RT-BOXes is considered to have entered through (i) gaps in the wall surface caused by aging or (ii) the outdoor unit of the air conditioner installed outside RT-BOXes. Accordingly, to curtail salt adhesion inside an RT-BOX, a commercially available salt-resistant filter was fitted to the outdoor unit of the air conditioner, as shown in Fig. 5. The amount of adhered salt at seven locations in the RT-BOX before and after fitting the filter are compared in Fig. 6.

It was observed that the amount of adhered salt in all locations decreased after the filter was fitted. It can thus be concluded that the filter effectively prevents salt from entering the RT-BOX. Note that two locations still gave values close to 50 mg/m2 (the standard for salt-affected areas) after the filter was fitted, but those values may be due to salt accumulated inside the RT-BOX prior to the filter fitting. It is thus necessary to remove that salt by carefully cleaning without dispersing salt particles during cleaning. These measures to prevent salt from infiltrating an RT-BOX are thought to contribute to preventing the corrosion of steel walls inside the facility as well as equipment failure and other malfunctions. 4. ConclusionTo protect telecommunication facilities from corrosion damage caused by salt, it is necessary to (i) apply appropriate heavy-duty anti-corrosion coatings to facilities outdoors where direct contact between steel plates and salt occurs and (ii) implement countermeasures such as fitting filters to prevent salt from entering from outside and accumulating inside the facilities. The application of these countermeasures will prolong the service life of facilities, especially in salt-affected areas along the coast. TASC will continue to promote technical cooperation to solve problems in the field, such as problems related to equipment deterioration due to corrosion from salt damage, and contribute to improving the quality and reliability of telecommunication services. References

|

|||||||