1. Introduction

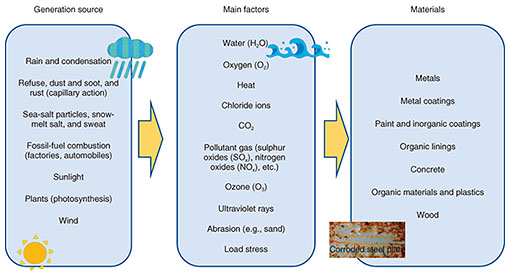

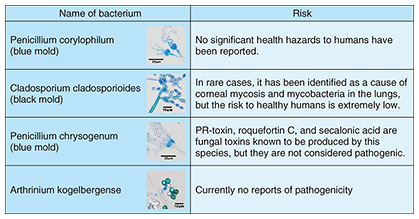

Telecommunication equipment and facilities are composed of various materials, including metals, concrete, and plastics, which degrade with prolonged use. The rate of degradation of those materials depends on the environment in which they are installed. Consequently, some equipment and facilities may degrade at a significantly higher rate than others and may subsequently fail or cause accidents. As shown in Fig. 1, the degradation progresses due to many factors in the environment in which the equipment or facility is installed [1]. It is known that natural and climatic phenomena cause the degradation. For example, particles of sea salt cause corrosion to metallic materials called “salt damage” and ultraviolet rays contained in sunlight cause damage to organic materials. On the other hand, organisms have been reported to cause unique failures. For example, cicadas, rats, etc. have been reported to damage aerial communication facilities and cause failures [2]. We have also received inquiries from the field about mold growth and the possibility of its impacts on material degradation depending on the environment surrounding telecommunication equipment and facilities. In this article, two case studies investigating the occurrence of mold in telecommunication equipment and facilities and its impacts on the materials of the equipment and facilities are presented.

Fig. 1. Major factors affecting degradation of materials in air.

2. Characteristics of mold and their impacts on telecommunication equipment and facilities

Mold can be found in people’s homes and even suspended in the air; in other words, it can be found everywhere—indoors and outdoors. It is also important to note that some molds are known to pose a health hazard to the human body. Mold grows when spores implant in various environments and grow into mold while absorbing nutrients and moisture through the tips of their fungal filaments. After a while, more spores are dispersed from the mold and spread through the air. Mold growth primarily requires nutrition, the right temperature, and moisture (humidity) [3]. The temperature range in which mold can grow is 0 to 40°C, in which the optimum growth temperature is 25 to 28°C. Moisture is also essential for mold growth. A decrease in moisture content causes a decrease in the growth rate of mold and eventual cessation of growth. To maintain a mold-free environment, relative humidity of the environment in question must be kept below 60% constantly regardless of temperature changes [4].

Metal corrosion also proceeds when oxygen and moisture (humidity) coexist as major factors (Fig. 1). If the environmental temperature increases, the reaction rate of such corrosion increases and may accelerate degradation of materials. The fact that mold is generated and continues to grow without dying suggests that the humidity of the environment in which the telecommunication equipment is installed is maintained at a consistently high level. In other words, maintaining a mold-free environment effectively prevents material degradation.

This article presents two case studies on mold growth: one concerning the walls of an outdoor telecommunication box (Section 3), and the other concerning the machine room of a telecommunication center building (Section 4).

3. Investigation of foreign matter on the walls of an outdoor telecommunication box

3.1 Circumstances of foreign-matter generation

The first case study concerned the walls of an outdoor telecommunication box. We received reports of black adhering substances on some of the walls of an outdoor telecommunication box and peeling paint in some of the areas where the adhering substances are present. The condition of the wall surfaces of the telecommunication box in question is shown in Fig. 2. The local maintenance personnel requested the Technical Assistance and Support Center (TASC), NTT EAST to investigate and identify any foreign matter adhering to the walls and determine its impact on the paint peeling.

Fig. 2. Appearance of outdoor telecommunication box. Left: side with poor sunlight; right: side with good sunlight.

3.2 On-site environmental investigation and analysis of foreign matter

To identify adhering substances of foreign matter on walls of the telecommunication box, we conducted (1) a visual inspection and (2) observation and analysis of adhering substances. We also conducted (3) an adhesion test of wall paint to determine the degradation of the exterior-wall paint.

(1) Visual inspection

Visual inspection revealed adhering substances on the exterior wall of the outdoor telecommunication box. We observed no adhering substances on the walls of the box that received plentiful sunlight due to the location of the facility; to the contrary, we observed adhering substances on the walls that received poor sunlight. We also observed peeling paint on the wall surfaces where the adhering substances were observed (Fig. 3). In contrast, we observed no significant peeling of the paint on the walls without adhering substances of foreign matter.

Fig. 3. Adhering substances and peeling paint on the wall.

(2) Observation and analysis of adhering substances

We observed the adhering substances on the walls using optical microscopy and scanning-electron-microscope energy-dispersive X-ray spectroscopy (SEM-EDS) (Fig. 4).

Fig. 4. Adhering substances on the walls. Top: optical-microscope image; bottom: SEM image.

The results of the EDS analysis indicate that the adhering substances were mainly composed of carbon and oxygen, i.e., organic matter. The environment surrounding the outdoor telecommunication box in question, which is located in a mountainous area, suggests that the adhering substances also contain organic matter such as moss and dust. However, the shape, size, color, and other characteristics of the spores observed in the SEM and optical-microscope images—as well as the fact that the adhering substances were observed mainly in the shade—confirmed that the adhering substances on the walls were molds.

(3) Adhesion test of wall paint

A paint layer with adhesion strength meeting the standard prevents oxygen and moisture from penetrating the wall surface and protects the steel materials composing the facility from corrosion. We therefore used the prescribed method to measure the overall adhesion strength of the paint on the walls of the outdoor telecommunication box. When we compared the adhesion strength of the paint on the walls with the adhering substances with that of the paint on the walls without the adhering substances, we found no difference in the adhesion strengths. We also confirmed areas of the walls of the entire telecommunication box in which the adhesion strength of the paint was below standard.

3.3 Considerations and countermeasures

The results of the above-described investigation confirmed the presence of mold in the adhered organic matter. Since we found areas with paint below the standard adhesive strength on the telecommunication box, regardless of the presence or absence of the adhering substances, we concluded that mold was not the direct cause of the decrease in adhesive strength of the paint. However, we presumed that the adherence of foreign matter such as mold created a high-humidity state, which further accelerated degradation such as the observed peeling of paint.

Mold like this and other adhering substances on walls can result in degradation of paint being overlooked and accelerate such degradation. It should thus be cleaned and removed from the walls of outdoor telecommunication boxes during inspection. When degradation is observed, such as a decrease in adhesion strength of the paint or peeling of paint, repairs such as repainting are necessary.

4. Investigation of foreign matter in the double floor of the machine room of a telecommunication center building

4.1 Circumstances of foreign-matter generation

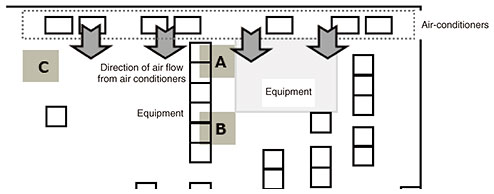

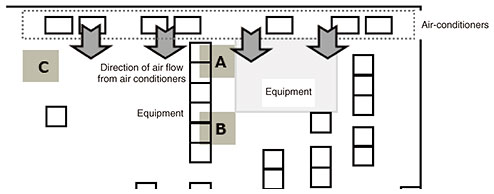

The second case study concerned a machine room of a telecommunication center building. A white foreign matter adhering to cables was founded in the double-layer floor of the machine room of a telecommunication center building. The layout of the equipment in the machine room is shown in Fig. 5.

Fig. 5. Layout of equipment in machine room.

White foreign matter was observed at locations A and B in the figure, but not at location C. The local maintenance personnel asked TASC to investigate this white foreign matter and determine if it was mold and what impacts it had on the equipment in the double floor and people’s health.

4.2 On-site environmental investigation and analysis of foreign matter

(1) Visual inspection

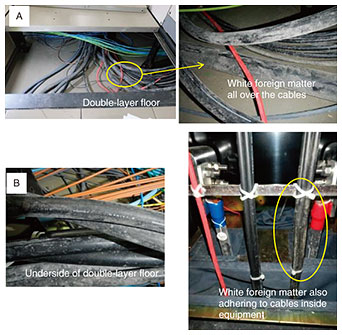

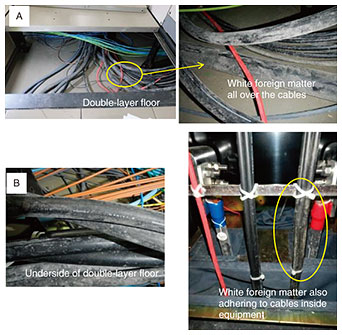

We inspected the detailed state of the foreign matter. As shown in Fig. 6, the foreign matter was found adhering to cables, the underside of the double-layer floor, and duct openings at locations A and B in the machine room. Upon checking around the inside of the equipment, we also found the foreign matter at the points at which the cables housed inside the equipment were installed above the floor.

Fig. 6. Condition of facilities.

(2) Measurement of temperature and humidity

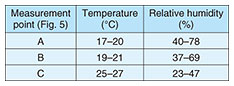

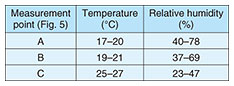

To investigate the cause of foreign matter occurring only in certain parts of the machine room, we installed temperature and humidity data loggers over a long period. We then investigated whether differences in temperature and humidity exist in the areas where the foreign matter was observed and the areas where not observed. The temperature and relative-humidity ranges for the measurement period (late April to early May) are listed in Table 1.

Table 1. Results of measuring temperature and humidity. (Range of measured values during the measurement period).

Compared with locations where no foreign matter was observed (location C in Fig. 5), the locations where foreign matter was observed (locations A and B) were found to be in a low-temperature, high-humidity environment.

(3) Observation and analysis of foreign matter

Component analysis and morphological observation of the collected foreign matter using SEM-EDS revealed that it was composed of about 50% carbon by weight, which indicates that organic matter was the main component, although magnesium, an inorganic element, was also detected at about 7% by weight. The magnesium is thought to be derived from magnesium hydroxide, which is a flame retardant contained in the outer sheath of the cables. Magnesium hydroxide is known to be harmless, non-toxic, and non-corrosive, so it is not expected to affect the human body or cables. Precipitation of magnesium from the surface of the cables is only trace amounts, and it has little impact on the flame resistance and electrical properties of the cables; therefore, continued use of the cables with magnesium precipitation should pose no problems.

(4) Mold culture test and analysis

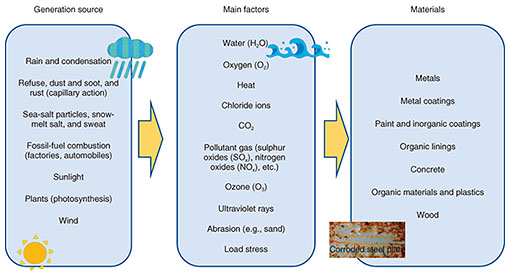

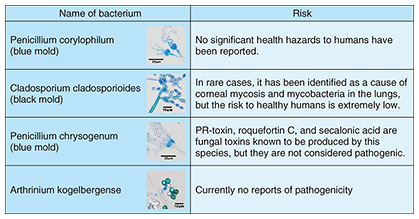

Considering the results of the above investigation and given that organic matter was the main component of the foreign matter, we assumed that the foreign matter was mold. Since the foreign matter was generated in the machine room, we had concerns about its impact on the human body. Accordingly, by collecting and culturing the foreign matter taken from the site, we conducted detailed analyses of the foreign matter by morphological observation, microbiological examination, and rDNA-sequence analysis to determine the fungal genus and species. The results of the analyses showed that the foreign matter was mainly blue mold (Penicillium) and black mold (Cladosporium), which commonly occur in living environments (Table 2). Both of these bacterial strains have been reported to have a low risk in regard to the human body.

Table 2. Results of culture test, analysis of molds and risks to human health.

4.3 Considerations and countermeasures

The main component of the foreign matter was mold, and the cause of growth of the mold was the high-humidity environment; therefore, to prevent mold growth, the relative humidity of the machine room must be kept constantly below 60% [3]. The presence of moldy and non-moldy areas in the same machine room also indicates that temperature and humidity are unevenly distributed in the room. Although the mold identified in this investigation is harmless to humans, the presence of a mold-prone environment in some parts of the machine room may cause condensation or other problems that may affect the equipment in the room.

Under those circumstances, two countermeasures to prevent recurrence of mold outbreaks are necessary: (1) remove the mold with ethanol-containing paper towels or other means; (2) check whether the current statuses of the outside-air inflow and the temperature and humidity distributions in the machine room are properly controlled, identify the cause of high humidity, and implement improvements to the air-conditioning system.

5. Concluding remarks

To protect telecommunication equipment and facilities from degradation due to adhesion of naturally occurring foreign matter, such as mold, it is necessary to regularly inspect outdoor equipment and facilities and check for the presence of foreign matter. If foreign matter is found, it should be removed by cleaning or other means. As for indoor equipment and facilities, for example, in a machine room, it is necessary to prevent the generation of foreign matter by appropriately controlling temperature and humidity of the room.

TASC will continue to engage in technical cooperation to solve problems in the field, such as degradation of equipment and facilities caused by natural phenomena and natural organisms and microorganisms, to contribute to improving the quality and reliability of telecommunication services.

References

| [1] |

Japan Society of Corrosion Engineering (ed.), “Introduction to Environmental Materials Science,” p. 170, Maruzen Publishing, Tokyo, Japan, 1994 (in Japanese). |

| [2] |

Technical Assistance and Support Center, NTT EAST (ed.), “Useful Q&A on Problems with Telecommunication Facilities in the Field (3rd Edition),” pp. 423–427, The Telecommunications Association, Tokyo, Japan (in Japanese). |

| [3] |

Hygiene & Microbiology Research Center, “Basic Knowledge of Mold” (in Japanese),

https://kabi.co.jp/basic-knowledge-of-kabi/ |

| [4] |

Ministry of Education, Culture, Sports, Science and Technology, “Countermeasures Manual for Mold—Basics” (in Japanese),

https://www.mext.go.jp/b_menu/shingi/chousa/sonota/003/houkoku/1211830_10493.html |