|

|||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||

|

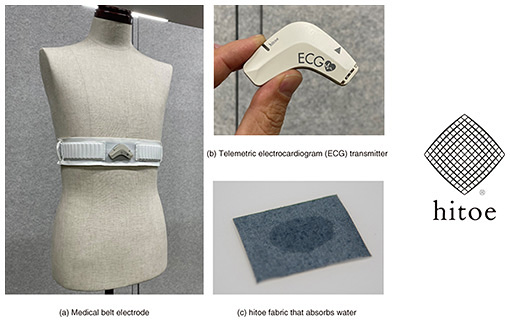

Feature Articles: Recent Updates on Bio-soft Materials Research Vol. 22, No. 5, pp. 18–23, May 2024. https://doi.org/10.53829/ntr202405fa1 Materials and Sensing Technologies for Constructing On-chip Biological ModelsAbstractBy creating unique process technologies of bio-friendly soft materials, such as hydrogels, and combining them with biomaterials, such as cells, the breadth of research and the potential for application of these technologies have dramatically increased. Under NTT’s Medical and Health Vision, new basic technologies are being developed to contribute to medical care and medicine. This article introduces the latest developments in bio-soft materials research at NTT Basic Research Laboratories. Keywords: soft materials, cells, on-chip biological models 1. Bio-soft materials research at NTT Basic Research LaboratoriesNTT Basic Research Laboratories (NTT BRL) has been conducting research on biointerfaces targeting information communication with the brain since the 1980s. Research on nano-bio devices combined with microfabrication technologies, such as semiconductors, and live imaging of biomolecules using a high-speed scanning probe microscope has been carried out [1]. NTT announced its Medical and Health Vision “Realization of Bio-Digital Twin” in November 2020 and has started developing medical and health support technology [2]. A bio-digital twin is a technology that creates a map of the body and mind in a virtual space to predict and simulate diseases. In addition to data science, NTT’s bio-soft materials research has been incorporated into this initiative to conduct basic research on devices such as bio-micro robots for diagnosis and treatment of the human body and organ-on-a-chips that reproduce the functions of the human body and organs on a device chip. This is an initiative that involves engineers and researchers in a wide range of fields, including devices, bioscience, and materials science, and is not limited to researchers in medicine and information science. For those who have been engaged in basic research on bio-soft materials at NTT BRL, this activity has broadened their visions from a narrow scope of communication with the brain to a wide range of device technologies that acquire biological information and technologies that artificially mimic biological functions. The development of the conductive fabric called hitoe™*1 is one of the first studies that led to the expansion of our vison and has its origins in the technique of coating surgical silk threads with the conductive polymer poly(3,4-ethylenedioxythiophene)-poly(styrenesulfonate) (PEDOT:PSS) in an experiment to detect neural activity in the mouse brain, which was originally conducted at NTT BRL. This fabric was developed jointly with Toray Industries, Inc. as a hydrophilic electrode material for detecting electrical potentials from the human skin such as electrocardiogram and electromyogram. In 2014, it was launched as sportswear for measuring heart rate [3]. More recently, services as medical devices have been developed and are expected to be powerful tools for measuring biological data for medical care, health, and well-being [4] (Fig. 1).

In bio-soft materials research at NTT BRL, not only the extension of traditional technologies and research themes but also new techniques and themes are being developed and promoted. The Feature Articles “Recent Updates on Bio-soft Materials Research” in this issue highlights research results obtained at NTT BRL related to on-chip biological models that reproduce cellular and biological functions on a chip and mimic biological movements, as well as results produced in combination with state-of-the-art sensing technology.

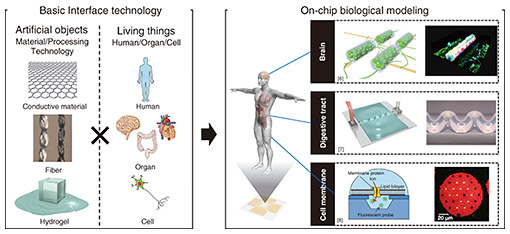

2. On-chip biological modelThe technology of materials processing has been becoming more sophisticated and finer with the progress in precision machinery and electronic devices, and at NTT laboratories, glass and semiconductor microfabrication technologies have evolved in line with the research and development of electrical and optical communication devices. In conventional bio-soft materials research, we tended to think in terms of making good use of current fabrication technologies, such as microfabrication of silicon semiconductors, to integrate with biotechnology. However, the combination of so-called hard and dry materials with advanced processing technologies is only one part of the expanding the possibilities of bio-soft materials research. Since 2016, when the Feature Articles “Forefront Research on Bio-soft Materials” was published in this journal [1], NTT BRL has been developing original processing technologies for bio-friendly materials (materials that can be safely placed in living bodies, grow cultured cells, and serve as scaffolds for cell culture), focusing on soft materials, rather than simply current processing technology. The pioneering research is the three-dimensional (3D) self-assembly of the silk-gel thin-film bilayer system [5]. This research has led to the creation of the on-chip cultured brain model using the graphene-parylene bilayer system, which is introduced in this issue [6]. The controlled buckling-delamination technique using a hydrogel thin film on a glass substrate was also established [7]. The principle of these two processing techniques is unique: they spontaneously form rolls and process them into channels by successfully controlling stresses resulting from differences in physical properties at the interface of foreign materials, which are rather undesirable in semiconductor substrate growth and processing. These unique processing technologies have led to the development of basic technologies such as the fabrication of 3D electrodes for detecting biological signals and the formation of flow channels with a wide variation in thin films. In 2023, dynamic control technology was developed to mimic the movement of living organisms by light irradiation. Since all these technologies involve using highly biocompatible materials, research has progressed rapidly, such as for fabricating a cell-culture scaffold and observing the movement of three-dimensionally formed cell tissues and biological signals (Fig. 2).

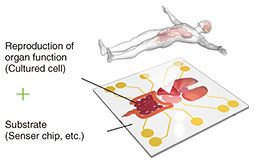

More details can be found in each article of this issue. With the self-assembly technology of graphene/parylene, which is introduced in the article “Brain-on-a-chip Model Using Deformable Graphene-based Electrode Array” [6], cells can be wrapped without a large load by spontaneously forming a 3D roll structure using a sacrificial layer, and a large number of cell masses can be cultured and a neural network can be formed on the chip between them. We succeeded in acquiring biological signals from each cell mass using this graphene as an electrode. With this self-assembly technology of graphene, it is also possible to control the roll diameter and 3D shape by controlling the number of graphene layers and thickness of the base material. With the buckling-delamination technology of hydrogel introduced in the article “Creation of Hydrogel Actuator toward Construction of On-chip Biological Models” [7], the flow path structure with variations is formed by controlling the adhesion pattern and hardness of hydrogel on a glass substrate, and the biomimetic motion is reproduced using photo-heat by synthesizing the photo-heat reactive hydrogel, thus enabling the action of blood vessel and intestine on the chip. Culturing cells on this hydrogel actuator is expected to lead to new developments in research combining the movement of the device and the flow in a channel with cultured cells. The article “Functional Evaluation of Bilayer Lipid for the Development of Artificial Cell-membrane Structures” [8] introduces the research progress on artificial cell membranes. An artificial cell membrane is a technology for reproducing on a chip the function of membrane proteins that exist in or on the surface of a cell membrane by covering microfabricated wells on a silicon semiconductor substrate with a lipid bilayer membrane, which is the substrate of the cell membrane. Regarding artificial-cell-membrane devices, we are studying methods to control phase-separated membranes caused by differences in lipid components on substrates and the introduction of recombinant membrane proteins by insect-cell-derived viruses. The development of a method for suppressing the electrical leakage caused by the flow of ions through the gap between the substrate and lipid film has been progressing and will be soon established as a sealing technology for electrophysiological measurement. 3. Contribution to precision medicineA device for reproducing organ function on a chip in vitro is called an organ-on-a-chip. It is attracting attention for being useful for drug-discovery research, personalized medicine, disease modeling, etc. (Fig. 3). Although simple organ-on-a-chips are commercially available, they are expected not only to reproduce individual organ functions but also replace animal experiments by mimicking more complex biological systems. However, this requires various factors that have not yet been developed, such as the shape of 3D organs, movement of living organisms, transport mechanisms of blood and body fluids, and communication mechanisms of nerves.

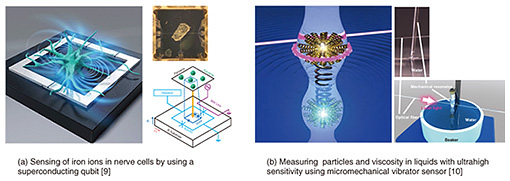

Since some organ-on-a-chips are available commercially, they are being used for medical research. In developing technology for practical devices, it is extremely important to clarify the purpose. In other words, without a clear purpose and what measurements you want to make, design guidelines will wobble, and eventually you will end up with a device that nobody can use. We should be aware that when we link research with the creation of devices for an application, the focus of research will shift to the application or combination of existing technologies and enhancing their performance to fulfill the requirements. The purpose of our research on on-chip biological models at NTT BRL is not the development for such practical devices, rather the creation of new functions by discovering new possibilities such as structure, motion, and sensing through synthesis and processing of bio-friendly materials. This has led to the development of technology that reproduces complex biological and biomimetic functions on a chip that cannot be achieved by extending conventional technologies. 4. Collaboration with highly sensitive sensing technologiesTo achieve more sensitive biosensing, NTT BRL is researching the combination of quantum technology and nano-mechanics technology (Fig. 4). The article “Characterization of Metal Ions in Neurons Using a Superconducting Flux Qubit” [9] in this issue introduces the sensing of iron ions in nerve cells by using a superconducting qubit. Superconducting qubits are not only the computational elements of quantum computers but are also very sensitive magnetic sensors that operate at ultra-low temperature. A superconducting flux qubit sensor can detect 20 electron spins (iron ions) and has a spatial resolution determined by its size (typically 10 to several micrometer square). This article introduces the measurement of the magnetization of nerve cells attached to a substrate. As this technology evolves, it is expected that trace metal elements can be analyzed with spatial resolution on a cell-by-cell basis. Although not introduced in this issue, research is underway on micromechanical vibrator sensors to detect the liquid properties and particles in liquids with ultra-high sensitivity [10]. High-sensitivity sensor technology, which has been used to target dry and hard materials such as metals and semiconductors, is expected to be applied to wet and soft bio areas.

5. Cherish the opportunity to encounter research partnersEven if our research topics are created from the bottom up, by connecting them with the issues of a research topic that we do not know much about, we may be able to find a new direction of using the research results and open up new applications. In fact, when the hydrogel fluidics device developed using our buckling-delamination technology introduced in this issue was exhibited at NTT R&D Forum, which is held every year by NTT laboratories, a professor from a medical institute suggested that the device could be used in experiments that would not be possible with conventional device chips. This is not to say that bottom-up basic research has nothing to do with what is actually useful, only that its orientation is not toward the development for specific practical devices. We believe that the on-chip biological models and sensing technologies introduced in this article can be used in various ways. It is important not to lose sight of the essence of research by pursuing the needs that have emerged, but we would like to conduct research so that we do not miss the progress made from new encounters. Toward effective coordination of such research, bio-soft materials research at NTT BRL promotes joint development and research in both Japan and overseas, mainly at the NTT Bio-Medical Informatics Research Center. Tetsuhiko F. Teshima, a senior research scientist at the Medical & Health Informatics Laboratories at NTT Research, Inc., who worked on 3D self-assembly of silk gel thin films and the graphene parylene bilayer system at NTT BRL, is currently conducting research based at the Technical University of Munich. In Japan, we also participate in World Premier International Premium Research Institute for Human Metaverse Medicine (WPI-PRIMe)*2 based at Osaka University. We will continue to carry out our research to open the frontiers of bio-soft materials by valuing new encounters in Japan and overseas.

References

|

|||||||||||||||||||||||||